In the modern industrial system, the capability to machine large and complex components often determines the ceiling of high-end manufacturing. When turbine casings for energy equipment need to withstand kiloton-level pressures, or propeller shafts for aircraft carriers require micron-level precision, the limitations of traditional machining processes become increasingly evident. Large-scale CNC machining technology, with its digitally driven precision control capabilities, is reshaping the production paradigm of heavy industry, serving as the core link between design creativity and engineering realization.

I. The Transformation from Virtual Blueprints to Physical Parts: A Technical Deconstruction of Large-Scale CNC Machining

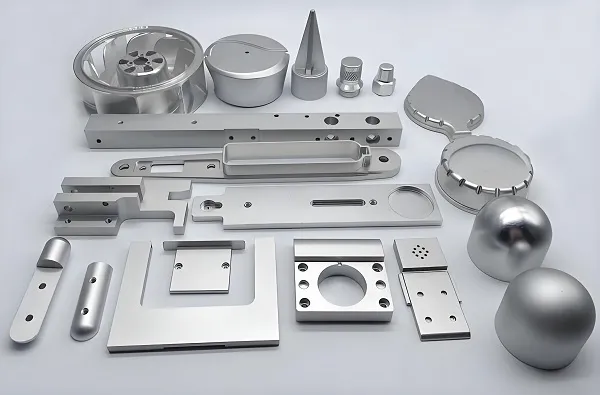

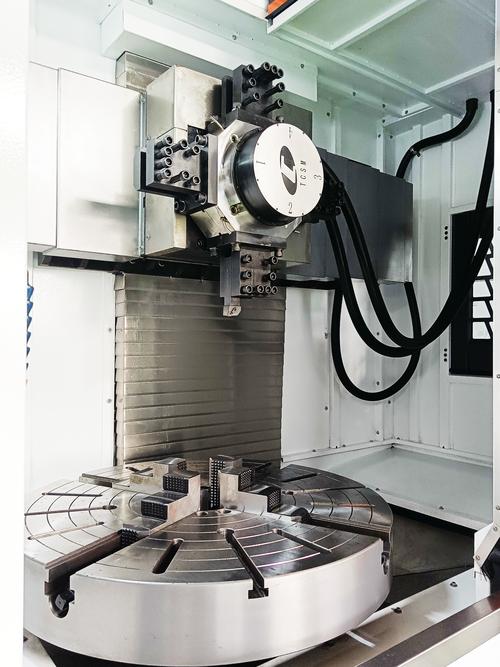

The essence of large-scale CNC machining lies in the precise control of heavy machine tools through computer numerical control (CNC) systems to achieve precision machining of complex workpieces measuring several meters in length and weighing multiple tons. Its core processes exhibit a high degree of intelligence:

- Digital Twin Construction: CAD software is used to create 3D models incorporating stress analysis and thermal deformation simulation. For example, when designing a main shaft for wind power equipment, virtual simulation is essential to verify its structural stability under extreme working conditions.

- Code Empowering Reality: CAM systems convert design models into G-code recognizable by machine tools. For large workpieces with long machining cycles, tool paths must be optimized to avoid precision deviations caused by thermal expansion, with some complex parts requiring millions of lines of code.

- Physical World Mapping: Specialized equipment such as five-axis gantry milling machines and horizontal boring machines come into play, achieving sub-millimeter workpiece positioning through laser alignment systems, and completing multi-stage machining from roughing to mirror polishing with automatic tool changers. Take the machining of a compressor cylinder for an energy enterprise as an example: its complex internal cavity requires 120 hours of continuous operation, with sensors monitoring tool wear and vibration data in real time.

II. Dual Challenges of Materials and Geometry: The Technical Thresholds of Large-Part Machining

Facing high-end demands such as aerospace titanium alloy frames and corrosion-resistant valve bodies for petrochemicals, large-scale CNC machining must overcome multiple technical barriers:

- Material Adaptability: The high hardness of titanium alloy causes tool wear three times faster than aluminum alloy, requiring coated cemented carbide tools and high-pressure cooling systems. The risk of interlaminar delamination in carbon fiber composite materials necessitates controlling cutting speeds at 60% of those for ordinary metals.

- Geometric Complexity: The twisted blade surfaces of marine propellers require five-axis (five-axis simultaneous motion) machining. Through the coordinated movement of rotary tables and main shafts, the tool axis is matched with the surface normal vector in real time to ensure a surface roughness of Ra0.8μm.

- Precision Maintenance: Thermal deformation of workpieces during machining can reach 0.1-0.3mm, requiring temperature-controlled workshops (accuracy ±0.5°C) and online laser measurement systems for dynamic error compensation. In machining a rocket fuel compartment for an aerospace enterprise, real-time closed-loop control kept the roundness error of the 3-meter-diameter compartment within 5μm.

III. Scenario Reconstruction in Heavy Industry: Full Industrial Chain Penetration from Energy to Aerospace

Large-scale CNC machining is becoming the infrastructure of high-end manufacturing, with application scenarios covering key sectors of the national economy:

- Frontline of the Energy Revolution: In nuclear power, the machining of reactor pressure vessel nozzles by CNC boring machines must meet the ASME code’s 0.01mm-level sealing surface accuracy requirements. For wind power, the machining of hundred-meter-level blade molds via gantry milling centers achieves one-time forming of complex flow channels.

- Heart of the Transportation Industry: In the machining of integrated die-casting molds for electric vehicles, large-scale CNC milling completes precise engraving of mold cooling water channels, increasing casting cooling efficiency by 40%. The machining of high-speed rail bogie welding frames uses multi-axis to achieve the optimal balance between weight reduction and strength.

- Aerospace Precision Manufacturing: The machining of honeycomb structures for satellite antenna reflectors requires vacuum adsorption fixtures and micro-milling technology to ensure surface accuracy reaches λ/10 (λ = working wavelength). The machining of multi-curvature nozzles for rocket engines relies on five-axis technology to achieve smooth transitions without tool marks.

IV. The Balancing Act of Efficiency and Precision: Core Advantages of Large-Scale CNC Machining

Compared with traditional machining methods, CNC technology demonstrates revolutionary breakthroughs:

- Integrated Manufacturing Philosophy: Multi-surface machining completed in a single setup on large machine tools reduces the number of processing steps for a heavy machinery gearbox housing from 8 to 2 in traditional processes, lowering assembly errors by 70%.

- Batch Consistency: In the CNC machining of automotive panel molds, repeat positioning accuracy reaches ±0.005mm, ensuring part size fluctuations remain below 0.02mm during millions of stamping productions.

- Whole-Life Cycle Cost Optimization: Although the initial investment in large machine tools can reach tens of millions, automated machining reduces manual intervention by 70%, and material utilization increases from 55% in traditional processes to 85%. In scenarios with annual production exceeding 1,000 units, the cost per part is reduced by over 30%.

V. Breaking Through Manufacturing Boundaries: Xiamen Goldcattle’s Technical Edge

In the large-scale CNC machining arena, Xiamen Goldcattle has built a competitive edge through end-to-end technical capabilities. Its large-scale turning-milling composite centers can machine super-large rotating parts with a diameter of 2.5 meters and a length of 12 meters. Through a real-time thermal deformation compensation system, cylindricity error is controlled within 0.015mm/m. The laser interferometer calibration system installed on its five-axis vertical machining centers ensures machining accuracy of complex cavities reaches ±0.008mm. For titanium alloy structural parts in aerospace, its developed stepped cutting strategy increases machining efficiency by 45% while extending tool life by 200%.

Conclusion: Defining the Coordinates of Future Manufacturing

As large-scale CNC machining transforms human engineering imagination into precision entities, its significance extends beyond technological innovation. From pressure-resistant casings for deep-sea exploration equipment to fuel tanks for interstellar probes, this technology is defining the coordinates of high-end manufacturing. With the deep integration of AI algorithms and machine tool hardware, future large-scale CNC machining will evolve toward self-sensing and self-optimizing smart manufacturing, becoming the core key to unlocking the digital transformation of heavy industry. In this challenging field, every precise tool insertion remeasures the limits of manufacturing.