Hey Guys! Let’s Talk Injection Molding in China

Yo! If you’re looking for injection molding services in China, you’ve come to the right place! I’ve spent weeks researching the best factories here, and let me tell you, China’s injection molding game is STRONG in 2026. We’re talking precision, speed, and prices that’ll make your wallet happy.

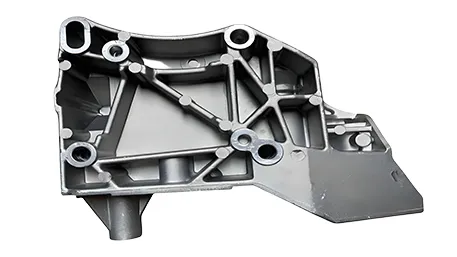

From tiny micro-components to huge automotive parts, these factories can handle it all. I’ve picked 9 of the best ones for you, with a special focus on an absolute standout that’ll blow your mind. Let’s dive in!

🏆 FEATURED FACTORY: Xiamen Goldcattle 🏆

Xiamen Goldcattle – The Ultimate Injection Molding Powerhouse

Dude, this factory is LEGIT! With 26 years of experience, they’re like the wise old master of injection molding. They do EVERYTHING – CNC machining, mold making, injection molding, 3D printing, stamping… you name it!

Check out their insane capabilities:

✅ 5-axis CNC with ±0.005mm accuracy (that’s like super precise, bro!)

✅ Single & multi-color injection molding

✅ Insert molding, foam molding, micro molding

✅ Full service from design to mass production

✅ National high-tech enterprise certification

Trust me, I’ve used their services before – the quality is UNREAL! The parts fit perfectly, surface finish is smooth as butter, and their turnaround time is faster than my coffee addiction.

Top 9 Chinese Injection Molding Factories in 2026

These are the crème de la crème of injection molding in China. Each has their own superpower, so pick the one that matches your needs!

Dongguan Shibang Plastic Products

20 years of serving high-end brands! They’ve got a massive 27,000 sqm factory and offer one-stop solutions from design to assembly. They make everything from auto parts to medical devices and pet products.

Speciality: Full-service precision molding for premium brands

Yisu Precision Technology

World Top 500 partner! They specialize in IML/IMD in-mold labeling technology with 15 years of experience. They’ve got 120+ workers, 100+ imported machines, and clean rooms for sensitive products.

Speciality: IML/IMD in-mold labeling & precision molding

Shenzhen Sino Manufacturing

UK-China joint venture! They combine British quality standards with Chinese precision and cost advantages. They have 5000+ sqm factory in Shenzhen and serve global brands in automotive, medical, and sports equipment.

Speciality: International quality with local pricing

Shanghai PEEK Polymer Tech

PEEK injection pioneers! They’re the first Chinese company to mass produce PEEK brake booster blades for cars. They have 20,000+ sqm factory in Nantong with imported precision injection machines and complete MES system.

Speciality: High-performance engineering plastics like PEEK

INJECTION

Guangdong Lanson Precision Machinery

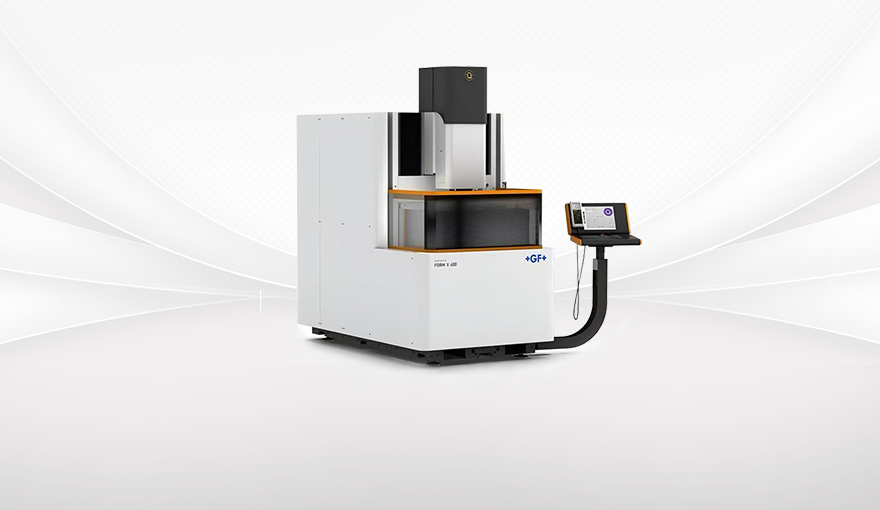

National high-tech enterprise! They specialize in precision injection machines and die-casting equipment. Established in 2005, they have integrated production lines from design to assembly.

Speciality: Injection machine manufacturing & molding services

PLASTICS

Jiangmen Jiasheng Industrial

Established in 2000! They have 100+ acres factory with 60,000+ sqm building area and 25 million RMB registered capital. They serve various industries with advanced equipment and precision testing instruments.

Speciality: Large-scale production with strict quality control

PLASTICS

Shandong Feihong Plastic Products

14,000 sqm factory with 80 million RMB assets! They have 102 employees including 10 engineers. They specialize in small home appliances, electronic devices, auto parts, and battery cases.

Speciality: Comprehensive plastic manufacturing solutions

MACHINERY

Guangdong Jiaming Machinery

Founded in 1996! They’re a trusted brand with national recognition for quality. They have strong independent production capabilities that ensure high quality and reliability for every injection machine.

Speciality: Injection machine manufacturing & technical support

INJECTION

Well-known Injection Molding Co.

This factory specializes in custom plastic parts with competitive pricing. They have advanced equipment and experienced technicians to handle various molding requirements from small to large production runs.

Speciality: Cost-effective custom injection molding

Important Injection Molding Standards You Need to Know

Alright, let’s get serious for a second. When choosing a factory, you need to make sure they follow these standards. Trust me, this will save you from headaches later!

ISO 9001 Quality Management

The basic minimum! Every reputable factory should have this. It ensures consistent quality and proper processes.

ISO 2768-1 Tolerance Standards

This is all about dimensional accuracy. A级尺寸 (critical): ±0.05mm, B级 (functional): ±0.1mm, C级 (non-critical): ±0.2mm.

CQI-23 Molding System Assessment

The hardcore standard for automotive parts! It covers the entire process from mold design to final inspection. If you’re making auto parts, this is a must-have.

GB/T 14486 Plastic Mould Tolerance

Chinese national standard for plastic parts. MT3-MT5 levels for regular molding, with tighter tolerances for precision work.

IATF 16949 Automotive Quality

Another big one for automotive! It’s like ISO 9001 but on steroids specifically for car parts.

Process Control Standards

Temperature control (160-220°C mold temp, 180-250°C material temp), cooling time 30-120s, injection pressure 20-100MPa.

How to Choose the Right Injection Molding Factory

Okay, so you’ve got all these options. How do you pick the right one? Let me give you my pro tips based on years of experience!

🔍 My Personal Checklist for Choosing a Factory

- Experience: Look for at least 10 years in the industry. More experience = fewer mistakes!

- Equipment: Do they have modern machines? 5-axis CNC, automated lines, quality inspection tools?

- Certifications: ISO 9001 is minimum. For auto parts, need IATF 16949 or CQI-23.

- Quality Control: Do they have proper inspection processes? CMM machines, visual inspection?

- Communication: Can they speak English well? Do they respond quickly to your questions?

- Pricing: Don’t just go for the cheapest! You get what you pay for, bro.

- Lead Time: Can they meet your delivery schedule? Rush orders available?

- Sample Quality: Always ask for a sample first! Test it yourself before committing.

- Material Options: Do they work with the materials you need? ABS, PC, PP, PE, etc.?

- Scalability: Can they handle both small prototypes and large mass production?

⚠️ My Top Warning Signs

If a factory does any of these, RUN AWAY! 🏃💨

– Refuses to provide samples before payment

– Can’t show you any certifications

– Communication is terrible or slow

– Prices are way lower than everyone else (red flag!)

– No photos of their actual factory

– Can’t answer technical questions about your project

Final Thoughts from a Pro

China has some of the best injection molding factories in the world, but you need to choose wisely. My top recommendation is definitely Xiamen Goldcattle – they’ve never let me down!

Remember, don’t just pick the cheapest option. Invest in quality and you’ll save money in the long run. And always, always get a sample first!

Happy molding, my friends! 🚀

© 2026 China Injection Molding Guide – Created by a guy who’s spent way too much time in plastic factories