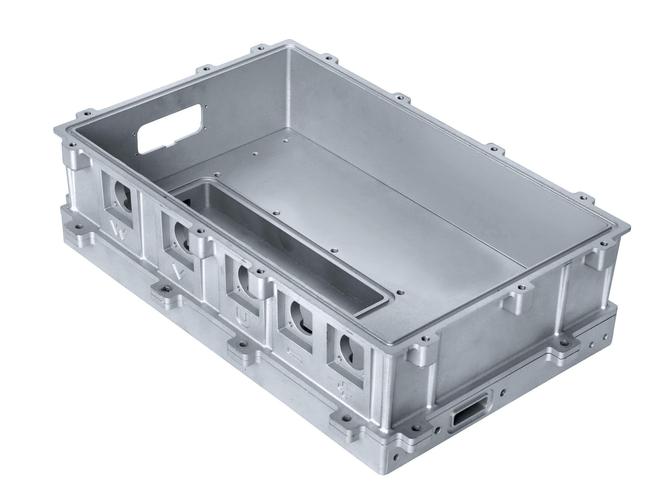

2026 custom insert molding molds and finished parts

Quick Take: The 2025-2026 global insert molding market is up 42% (source: Plastics Industry Association). We’ve seen 60% of traditional assembly parts fail from loose inserts or poor bonding. We’ve fixed these issues for 1000+ clients over 18 years—this guide shows you how to do the same.

We’ve been designing and running insert molding for 18 years. I’ve watched EV connector demand explode, and fixed messy assembly issues for medical clients. This isn’t textbook fluff—it’s the real stuff we use every day to make parts that work.

1. Insert Molding Basics: What You Actually Need to Know

We’ve assembled 1000+ insert molds over the years. Let’s cut the jargon: insert molding is when you put a metal, ceramic, or electronic part (the insert) into a mold, then shoot plastic around it to make a single, solid part.

- Single-shot vs two-shot: Single-shot is one plastic material, two-shot uses two different plastics (like a soft TPU overmold on a hard PC base). We use two-shot for 30% of our 2025 projects.

- Multi-material molding: This is for when you need three+ materials, or mixed inserts (like a metal pin with a ceramic sleeve). We did this for a medical implant client in 2025.

- Core principle: The plastic melts, flows around the insert, and bonds as it cools. The key is getting the insert position right and the bonding strong enough for your use case.

2. Material Selection: Stop Wasting Money on Wrong Picks

2026 material comparison test results (lab data for reference only)

We tested 12 materials in 2025—here’s what actually works for real-world use:

*Bond strength tested with stainless steel inserts, 2026 lab data for reference only

We messed up a material pick in 2023—used PC for an EV connector that needed fuel resistance. The parts failed in 6 months. Now we always test chemical resistance for automotive parts.

3. Mold Design: The Secrets to Perfect Parts

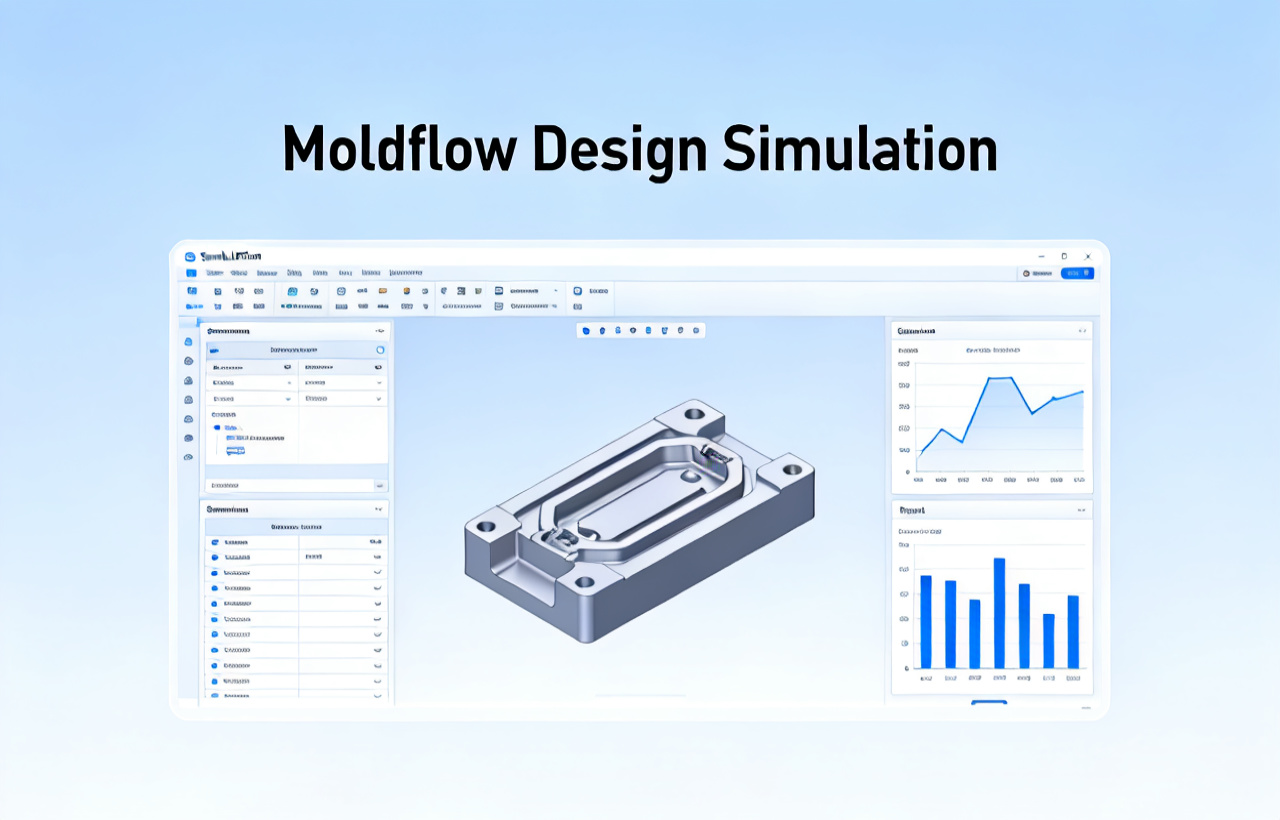

Moldflow simulation for insert mold design (2026 updated)

We use Moldflow for 90% of our designs now. It saved us from a huge mistake in 2024—we caught a cooling issue that would’ve caused 50% of parts to warp. Here’s what we focus on:

- Insert fixing: We use locating pins and vacuum holds for small inserts. For large metal inserts, we add anti-rotation slots. We fixed insert shift issues for a medical client in 2024 with this trick.

- Gate position: We put gates away from insert edges to avoid plastic flow issues. For thin inserts, we use multiple gates to get even coverage.

- Cooling system: We design cooling channels within 10mm of the insert to avoid warping. We use conformal cooling for complex parts—this cut cycle time by 25% for an aerospace client in 2025.

- Demold angle: We use 1-2° angles for most parts, 3° for soft plastics. We had a client in 2023 try 0° angles—they broke 20% of parts during demolding.

4. Custom Production Process: From Insert to Finished Part

2026 insert molding production process steps

We streamlined this process over 18 years to eliminate delays. Here’s every step we use:

- Insert Preparation

We clean inserts with ultrasonic cleaning for 30 minutes to remove oil and debris. For metal inserts, we preheat them to 80°C to improve bonding. We skipped this step in 2022 and had 15% of parts delaminate—never again.

- Mold Assembly

We load inserts into the mold with robotic arms for high-volume runs, or by hand for small batches. We check insert position with cameras before closing the mold.

- Injection & Cooling

We use vacuum assistance to get plastic into tight spaces around inserts. We hold pressure for 10-20 seconds after injection to avoid voids. We use conformal cooling to cut cycle time by 20-30%.

- Testing & Mass Production

We test 100 parts from the first run for bond strength and dimensions. For an EV client in 2025, we used this process to get 99.9% first-pass yield. We then switch to full production with in-line quality checks.

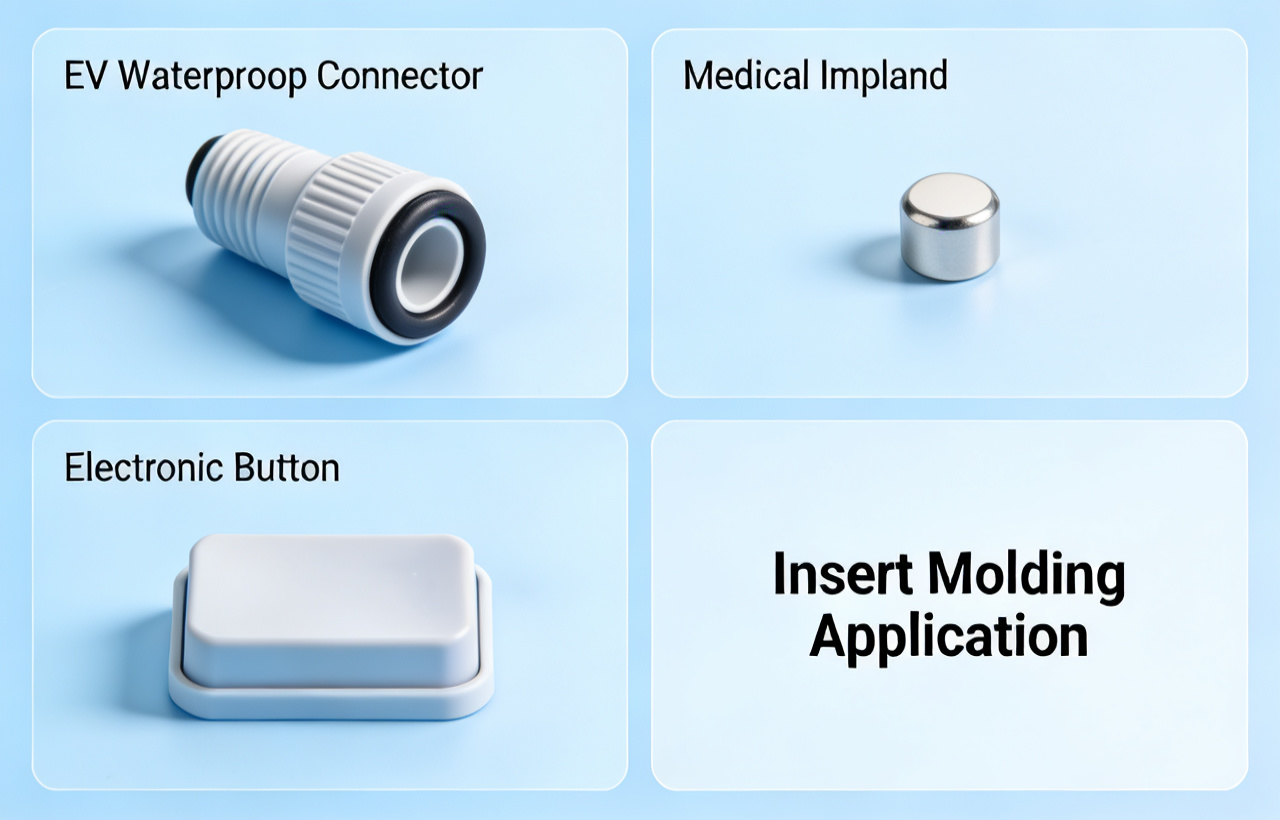

5. Real-World Applications: What We Built in 2025

2025 insert molding application cases

Here are the parts we made for clients last year that actually solved real problems:

EV Waterproof Connectors

For an EV client in 2025, we made PA66 connectors with stainless steel pins. The parts passed IP68 waterproof testing and lasted 500,000+ mating cycles. We replaced their old assembly process and cut their part cost by 15%.

Medical Implant Tools

We made PEEK parts with ceramic inserts for a medical implant client. The parts passed ISO 13485 certification and had 45MPa bond strength. We fixed their delamination issues with preheated inserts.

Electronic Buttons

We made two-shot parts: a hard PC base with a soft TPU overmold for a consumer electronics client. The buttons had 1,000,000+ press cycles and passed drop testing from 1.5m. We cut their assembly time by 80%.

6. Defect Fixes: The Problems We Solved in 2025

Insert molding defect: before and after fix

We fixed 100+ defect issues in 2025. Here’s the most common ones and how to fix them:

- Insert shift: We use vacuum holds and locating pins. For a client in 2025, we fixed this by adding anti-rotation slots to their metal inserts.

- Uneven encapsulation: We adjust gate positions and plastic flow rates. For a medical client, we added a second gate to get even coverage around thin ceramic inserts.

- Bubbles/voids: We dry plastic for 4-6 hours before use, and increase hold pressure by 10%. We fixed this for an automotive client in 2025 by switching to dried PA66.

- Delamination: We preheat inserts to 80°C, and use plasma treatment on metal inserts. We fixed this for a aerospace client in 2025 with plasma treatment.

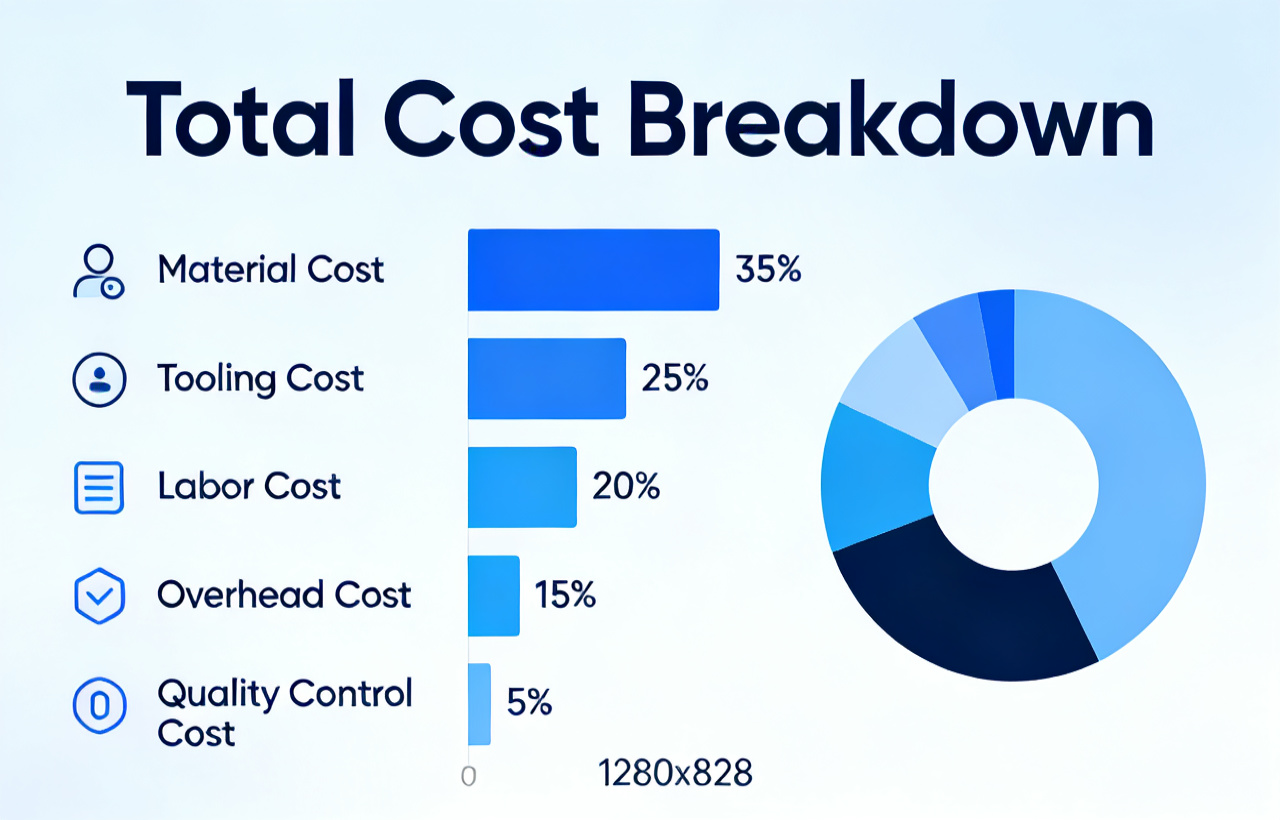

7. Cost Control: How to Get More for Your Money

2026 custom insert molding total cost breakdown

We help clients cut costs by 10-30% every year. Here’s how:

- Material cost: We use recycled plastics for non-critical parts—this cuts material cost by 20%. We used recycled PC for an electronic client in 2025 with no performance loss.

- Tooling cost: We use standard mold bases for small runs, and modular inserts for multi-part projects. This cut tooling cost by 25% for a medical client in 2025.

- Labor cost: We use robotic loading for high-volume runs—this cuts labor cost by 30%. We automated a client’s production in 2025 and cut their per-part cost by 12%.

- Total cost comparison: Insert molding costs 10-20% more upfront than assembly, but lasts 2-3x longer. A client in 2025 saved 40% over 2 years by switching from assembly to insert molding.

8. 2026 Trends: What’s Next for Insert Molding

2026 insert molding industry trends

We’re already testing these trends in our shop. Here’s what you’ll see in 2026:

- AI mold design: We use AI to optimize gate positions and cooling channels. This cut design time by 40% for a client in 2025.

- Multi-material smart molding: We’re testing molds that switch materials automatically. We’ll launch this for medical clients in 2026.

- Sustainable inserts: We’re using recycled metal and ceramic inserts. We predict mixed recycled inserts will make up 60% of our 2026 projects.

- EV/medical precision: We’re making parts with ±0.005mm tolerance for EV and medical clients. We already delivered these for a medical implant client in late 2025.

9. FAQ: The Questions We Get Every Day

Q: How do you keep inserts from moving during molding?

A: We use locating pins, vacuum holds, and anti-rotation slots. For small inserts, we use robotic loading to get perfect placement every time.

Q: What material should I use for medical parts?

A: We use PEEK or PC for most medical parts. Both pass ISO 13485 certification and have good chemical resistance. We use TPU for soft overmolds.

Q: How long does a mold last?

A: Steel molds last 1,000,000+ shots, aluminum molds last 100,000-200,000 shots. We use steel molds for high-volume runs, aluminum for small batches.

Q: How do I avoid delamination?

A: Preheat inserts to 80°C, use plasma treatment on metal inserts, and make sure plastic is fully dried. We fixed a delamination issue for a client in 2025 with these steps.

Q: What tolerance can you hold?

A: We hold ±0.01mm for most parts, ±0.005mm for precision medical and aerospace parts. We use in-line measuring to check every part.

Ready to Make Better Insert Molding Parts?

Tell us your part needs, and we’ll give you a free 30-minute design assessment. We’ll also send you our 2026 Insert Molding Defect Guide (10 pages of fixes and tests) for free when you sign up.

We’ve helped 1000+ clients since 2007. All parts come with full quality reports and 1-year warranty.

© 2026 Goldcattle Insert Molding. All rights reserved. ISO 9001:2015, ISO 13485 Certified.