1. Key Technology Comparison

Structured analysis of injection molding and 3D printing for mold manufacturing:

| Criteria | Traditional Injection Molding | 3D Printed Molds |

|---|---|---|

| Lead Time | 20-25 days (CNC machining, polishing) | 6-48 hours (direct printing + post-processing) |

| Cost (1,000 Parts) | 15,000−50,000 (steel/aluminum tooling) | 500−5,000 (polymer/composite molds) |

| Durability | 100,000+ cycles (steel) | 50-10,000 cycles (material-dependent) |

| Design Complexity | Limited by CNC/EDM capabilities | Freeform geometries, conformal cooling channels |

| Sustainability | High material waste (30%+ in machining) | Near-zero waste (additive process) |

2. Niche Applications Driving Customization

A. 3D Printing Dominates in:

- Prototyping & Low-Volume Production

- Case: PepsiCo reduced blow mold development from 4 weeks to 12 hours using Nexa3D’s xPEEK147 resin.

- Ideal for startups validating product-market fit.

- Medical & Dental Devices

- Patient-specific implants (e.g., hearing aids, surgical guides) require <100 units.

- Complex Cooling Systems

- Conformal channels boost cycle efficiency by 40% in automotive molds .

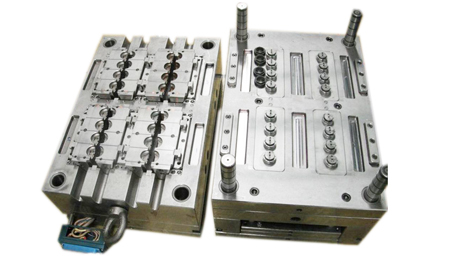

B. Injection Molding Excels in:

- Mass Production (>10,000 parts)

- Automotive components (e.g., dashboards, connectors) demand steel durability.

- High-Temperature Materials

- PEEK, Ultem require molds stable above 260°C.

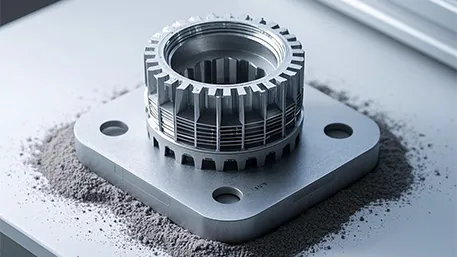

3. Material Innovations Bridging the Gap

3D Printing Materials for Demanding Tooling:

| Material | Key Properties | Use Cases |

|---|---|---|

| xPEEK147 (Nexa3D) | 180°C HDT, chemical resistance | Food-grade packaging molds |

| Rigid 10K (Formlabs) | Glass-filled resin, 100+ cycles | Consumer electronics prototyping |

| 18Ni300 (DMLS) | 50 HRC, 500°C thermal stability | Hybrid metal-polymer tooling |

Cost Trends (2023-2025):

- Metal 3D printing costs dropped to 0.8−1.2/g for tool steel, enabling 8k−12k molds for large automotive parts.

4. Decision Framework for Custom Tooling

Choose 3D Printing When:

✅ Rapid iteration (<1 week)

✅ <1,000 parts or complex geometries

✅ Budget <$10k

Choose Injection Molding When:

✅ High-volume orders (>10k units)

✅ Extreme thermal/mechanical demands

✅ Tolerances <±0.05mm

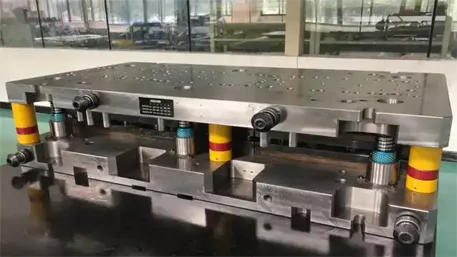

5. The Future: Hybrid Manufacturing

Leading EU/US manufacturers now adopt “Print-Last” strategies:

- 3D print molds for market testing.

- Transition to CNC-machined aluminum for mid-volume.

- Scale with steel molds post-validation.

Example: Humanetics (crash-test dummies) uses Markforged printers for customized inserts paired with legacy tooling.

Why This Matters for Custom Mold Buyers in 2025

- Speed-to-Market: Slash NPI cycles by 75% with printed tooling.

- Cost Control: Avoid $50k+ steel mold investments for unproven designs.

- Regulatory Edge: FDA/EU-compliant resins accelerate medical device approvals.

Action Tip: Partner with suppliers offering dual capabilities (e.g., Protolabs, Xometry) to flexibly scale production.