In the world of automotive manufacturing, the precision of every component directly impacts a vehicle’s performance and safety. 5-axis CNC machining technology, like a skilled craftsman, plays a crucial role in the production of automotive parts. Today, we’ll explore how this technology protects and escorts automotive parts from multiple dimensions including materials, processes, and workflows.

What Exactly is 5-Axis CNC Machining?

Some people might not be very familiar with 5-axis CNC machining. Simply put, traditional 3-axis machining can only move in three linear directions (X, Y, Z), similar to cutting with a knife on a flat surface with fixed angles. 5-axis CNC machining, however, adds two rotational axes (usually A and C axes) to these three linear axes. This is like equipping the cutting tool with flexible “joints,” allowing it to approach the workpiece from various angles and easily handle complex machining requirements.

With these two rotational axes, 5-axis CNC machining achieves synchronous movement of the workpiece in five degrees of freedom. This means it can complete multi-face machining in a single setup, significantly reducing errors caused by multiple setups and greatly improving machining precision and consistency. Current mainstream 5-axis CNC machines can achieve positioning accuracy of ±0.001mm and repeatability accuracy of ±0.0005mm, providing a solid foundation for high-precision automotive part machining.

Why Automotive Parts Can’t Do Without 5-Axis CNC Machining?

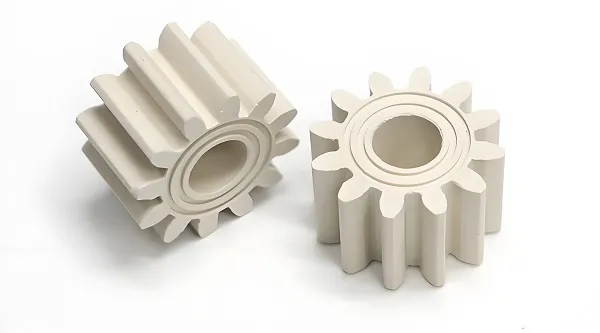

Many automotive parts have complex shapes and extremely high precision requirements, such as engine blocks, cylinder heads, and transmission gears. These parts, if produced using traditional machining methods, would be inefficient and difficult to ensure precision. 5-axis CNC machining perfectly solves these problems.

Take the engine block, for example, which contains many complex oil passages, water channels, and combustion chambers. The precision of these structures directly affects engine power and fuel consumption. 5-axis CNC machining can accurately produce these complex structures, allowing the engine to perform at its best. Moreover, with 5-axis CNC machining technology, the machining precision of engine blocks can reach ±0.01mm, fully meeting the strict requirements of automotive assembly.

In automotive mold manufacturing, the advantages of 5-axis CNC machining are even more prominent. Many automotive components such as body panels and interior parts rely on molds for forming, and mold precision directly determines part quality. Previously, manufacturing a set of automotive molds might take 15 days, but with 5-axis linkage technology, the machining cycle is reduced to 5 days, improving efficiency by 66%. This not only accelerates the development of new vehicle models but also reduces production costs.

Core Materials and Applications in 5-Axis CNC Machining of Automotive Parts

Automotive part machining involves a variety of materials, and 5-axis CNC machining has good adaptability to different materials, fully utilizing the performance advantages of each material.

Aluminum Alloys: The Mainstay of Lightweight Materials

Aluminum alloys are the most widely used lightweight materials in automotive part machining, with 6061 and 7075 being the most commonly used grades. 6061 aluminum alloy has moderate strength (tensile strength around 310MPa) and good weldability, widely used in automotive body frames and chassis structural parts; 7075 aluminum alloy has higher strength (tensile strength up to 572MPa), close to that of steel, commonly used in engine brackets, suspension systems, and other load-bearing components.

5-axis CNC machining of aluminum alloys demonstrates excellent performance: cutting speeds can reach 200-500m/min, feed rates 0.1-0.3mm/r, and material removal rates as high as 16,400 cm³/min, 2-3 times that of traditional 3-axis machining. In the machining of new energy vehicle battery trays, a company using 5-axis linkage technology to process 6061 aluminum alloy trays not only controlled dimensional accuracy within ±0.02mm but also reduced the processing defect rate from 25% to 5%, increasing daily output of a single production line by 30 units.

Mold Steels: The Foundation of Precision Molds

High-performance mold steels are essential for automotive mold manufacturing, with H13 and P20 being representative materials. H13 hot-work die steel, after quenching and tempering, can reach a hardness of 42-48HRC, offering excellent hot strength and wear resistance, mainly used in automotive engine block die-casting molds and hot forging dies; P20 pre-hardened plastic mold steel has a hardness of 28-32HRC and good machinability, suitable for manufacturing injection molds for automotive interior parts.

5-axis CNC machining of mold steels adopts a layered machining strategy: in the roughing stage, 70%-80% of the allowance is removed using 16-20mm diameter carbide end mills with cutting speeds of 50-80m/min and feed rates of 0.1mm/r; semi-finishing uses 10mm tools to improve precision to ±0.01mm; finishing employs 6mm ultra-fine grain carbide tools, controlling surface roughness to Ra 0.4-0.8μm. Data from an automotive mold factory shows that 5-axis machining of H13 steel molds achieves pre-polishing surface precision of Ra 0.8μm, reducing polishing time by 50% compared to traditional machining.

Magnesium Alloys: The Choice for Ultimate Lightweighting

Magnesium alloys are currently the lightest structural materials in the automotive industry, with a density of only 1.74g/cm³, 30% lighter than aluminum alloys. AZ91D is the most commonly used die-cast magnesium alloy, with a tensile strength of 230MPa, used in transmission housings, instrument panel brackets, and other parts. However, magnesium alloys have high chemical activity, posing fire hazards during cutting, requiring special processing equipment and techniques.

5-axis CNC machining of magnesium alloys must use dedicated cooling systems with cutting fluid flow rates not less than 20L/min, cutting speeds controlled at 100-300m/min, and feed rates of 0.15-0.25mm/r. A luxury car brand using 5-axis technology to process AZ91D transmission housings reduced part weight by 2.3kg while shortening machining time to 45 minutes per piece through optimized tool paths, improving efficiency by 40% compared to 3-axis machining.

Stainless Steels: The First Choice for Corrosion-Resistant Components

Automotive exhaust systems, fuel lines, and other corrosion-resistant components mainly use 304 and 430 stainless steels. 304 stainless steel contains 18% chromium and 8% nickel, offering excellent corrosion resistance but being difficult to cut; 430 ferritic stainless steel contains no nickel, has lower cost, and is suitable for decorative components. The biggest challenge in stainless steel machining is severe work hardening, with hardened layer depths reaching 0.1-0.3mm.

5-axis CNC machining of stainless steels uses PCBN (polycrystalline cubic boron nitride) tools with cutting speeds of 80-150m/min, feed rates of 0.08-0.15mm/r, and cutting depths controlled within 0.5-1mm. Data from an exhaust system manufacturer shows that 5-axis machining of 304 stainless steel flanges achieves surface roughness of Ra 1.6μm and dimensional accuracy of ±0.015mm, extending tool life by 3 times compared to traditional machining.

Key Process Links in 5-Axis CNC Machining of Automotive Parts

5-axis CNC machining of automotive parts is a complex process involving multiple key links, each affecting the final part quality.

Tool path planning is a crucial link. 5-axis CNC machining can generate precise tool paths through computer-aided manufacturing software, like planning the optimal “route” for the cutting tool. In machining complex curved automotive parts, curvature-based adaptive isoparametric strategies are adopted to adjust tool path spacing according to surface curvature changes, ensuring machining precision while improving efficiency. For example, in machining complex curved parts like automotive engine blades, reasonable tool paths allow uniform cutting, reducing surface errors.

Cutting parameter settings directly affect machining results. For easily machined materials like aluminum alloys, cutting speeds can typically reach 200-500m/min with feed rates of 0.1-0.3mm/r; for harder materials like mold steels, cutting speeds are reduced to 30-80m/min with feed rates around 0.05-0.1mm/r. Appropriate cutting parameters reduce tool wear, ensure machining surface quality, and avoid issues like built-up edges that affect part precision.

Cooling and lubrication are also essential process links. During 5-axis CNC machining, friction between the tool and workpiece generates significant heat, especially when machining high-hardness materials. Good cooling and lubrication reduce cutting temperatures, minimize tool wear, and improve machining precision. Many current 5-axis machining equipment are equipped with efficient cooling systems that accurately deliver cutting fluid to the cutting area, ensuring stable machining processes.

Complete Workflow of 5-Axis CNC Machining for Automotive Parts

5-axis CNC machining of automotive parts follows a standardized workflow, with each step from pre-preparation to final inspection being crucial.

First is drawing analysis and process planning. After receiving design drawings of automotive parts, technicians analyze part structure characteristics, precision requirements, and material properties, then develop detailed machining process plans including determining machining sequences, selecting tools and fixtures, and planning cutting parameters. For example, when machining automotive transmission gears, roughing, semi-finishing, and finishing sequences are planned based on gear tooth precision requirements and material hardness.

Next is programming and simulation. Programmers write 5-axis machining programs using professional CAM software based on process plans to generate tool paths. The programs are then verified through solid cutting simulation software to check for tool overcutting, interference, and other issues, like conducting a “simulated machining” in advance to identify and modify program errors, preventing problems during actual machining.

Then comes workpiece clamping and tool setting. The blank material is fixed on the 5-axis CNC machine table using fixtures to ensure secure clamping. Tool setting determines the relative position between the tool and workpiece, with tool length and diameter accurately measured using a tool setter and data input into the machine system to ensure machining dimensional accuracy.

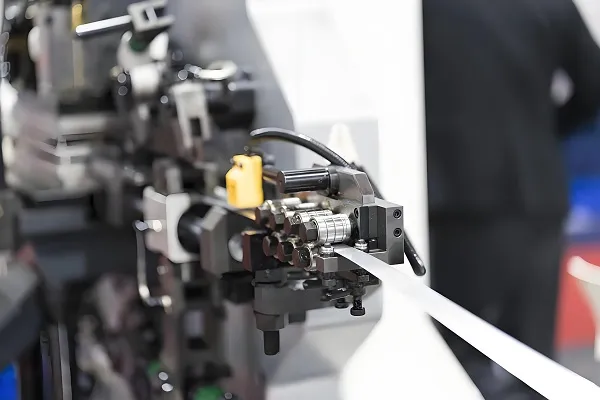

In the formal machining stage, the machine operates automatically according to the programmed instructions, with the tool cutting in 5-axis linkage. During machining, operators monitor machine operation in real-time, observing cutting conditions and cooling system performance to ensure stable machining processes.

After machining is completed, parts undergo quality inspection. Precision testing equipment like coordinate measuring machines are used to check if part dimensional accuracy and geometric tolerances meet design requirements. If issues are found, causes are analyzed and rework is performed until part quality meets standards.

Common Questions About 5-Axis CNC Machining of Automotive Parts

What considerations are there for tool selection when machining different automotive part materials with 5-axis CNC?

For softer materials like aluminum alloys, high-speed steel or coated carbide tools are typically used, as these tools have high sharpness and reduce built-up edge formation; for hard materials like mold steels, carbide or CBN tools are chosen for their high hardness, wear resistance, and ability to withstand high cutting forces. Additionally, tool geometric parameters matter—sharper cutting edges are used for ductile materials, while slightly duller edges work better for brittle materials.

How to ensure surface quality when machining automotive molds with 5-axis CNC?

First, optimize cutting parameters by reasonably controlling cutting speed, feed rate, and depth of cut to avoid surface roughness caused by improper parameters; second, select appropriate tools with sharp cutting edges to minimize surface impact from tool wear; ensure adequate cooling and lubrication during machining to reduce surface quality damage from frictional heat; finally, optimize tool paths using smooth cutting trajectories to reduce cutting force fluctuations, ensuring mold surface roughness meets Ra 0.4-0.8μm requirements.

How much more efficient is 5-axis CNC machining for automotive parts compared to traditional machining?

The advantages are significant for complex parts: in automotive mold machining, traditional methods might take 15 days, while 5-axis linkage technology reduces this to 5 days, improving efficiency by 66%; for complex parts like engine blocks, 5-axis machining completes multi-face processing in one setup, reducing clamping time and improving overall efficiency by 40%-60%. Additionally, material removal rates are higher—5-axis CNC achieves 2-3 times the material removal rate of traditional 3-axis machining for aluminum alloys.

Is 5-axis CNC machining suitable for small-batch automotive part production?

Absolutely. For small-batch production, 5-axis CNC machining completes multiple processes in one setup, reducing fixture investment and lowering production costs. Although initial investment in 5-axis equipment is higher, small-batch production avoids allocating large mold costs while ensuring part precision and consistency. 5-axis CNC machining is a cost-effective choice for custom automotive components or small-batch production during new vehicle development stages.