Abstract: With the rapid development of modern manufacturing industry, five-axis CNC machining technology has become one of the key technologies for manufacturing high-precision and complex-shaped parts. This article aims to explore the technical characteristics, application advantages and future development trends of 5-axis CNC machining parts. Through detailed analysis of the principle, process and application cases of five-axis CNC machining technology in fields such as automobiles, aerospace and medical devices, this article reveals the significant advantages of 5-axis CNC machining parts in improving production efficiency, reducing production costs and enhancing product quality, and looks forward to its future development prospects.

I. Introduction

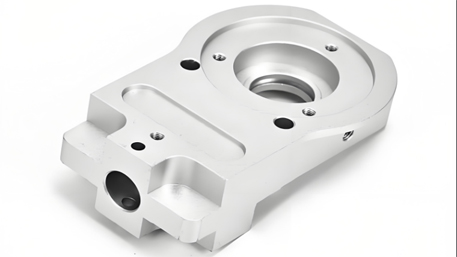

As an important part of modern manufacturing industry, five-axis CNC machining technology plays an increasingly important role in the field of parts manufacturing with its characteristics of high precision, high efficiency and high flexibility. Five-axis CNC machine tools can achieve one-time processing of complex-shaped parts by simultaneously controlling the movement of five axes, greatly improving processing efficiency and product quality. This article will deeply explore the technical characteristics, application advantages and future development trends of 5-axis CNC machining parts.

II. Overview of Five-axis CNC Machining Technology

Technical principle: Five-axis CNC machining technology is based on the traditional three-axis CNC machining technology, adding two rotational axes (usually A axis and C axis), thereby realizing the simultaneous control of the part in five directions. This technology can achieve one-time processing of complex-shaped parts, avoiding the errors caused by multiple clamping and positioning.

Process: The five-axis CNC machining process includes parts design, programming, processing and inspection. First, the part is designed through CAD software, and then programming is carried out using CAM software to generate the processing path and tool trajectory. Then, the programming data is input into the five-axis CNC machine tool for processing. Finally, the processed part is inspected through inspection equipment to ensure it meets the design requirements.

III. Application Advantages of 5-axis CNC machining parts

Improve production efficiency: Five-axis CNC machining technology can achieve one-time processing of complex-shaped parts, avoiding the time waste caused by multiple clamping and positioning, thereby improving production efficiency.

Reduce production costs: Since five-axis CNC machining technology can reduce material waste and manual intervention in the processing process, production costs can be reduced. In addition, by optimizing the processing path and tool trajectory, the processing cost can be further reduced.

Improve product quality: Five-axis CNC machining technology has the characteristics of high precision and high flexibility, which can achieve precise control of the part shape, thereby improving product quality. In addition, since the errors caused by multiple clamping and positioning are avoided, the accuracy and consistency of the parts can also be improved.

IV. Application Cases of 5-axis CNC machining parts

Automotive industry: In the automotive industry, five-axis CNC machining technology is widely used in the processing of complex-shaped parts such as engine blocks, cylinder heads and suspension systems. Through five-axis CNC machining technology, one-time processing of these parts can be achieved, improving production efficiency and quality.

Aerospace: In the aerospace field, five-axis CNC machining technology is used to manufacture high-precision parts such as aircraft structural parts and engine components. These parts have complex shapes and strict precision requirements, and these requirements can be met through five-axis CNC machining technology.

Medical devices: In the field of medical devices, five-axis CNC machining technology is used to manufacture high-precision parts such as surgical instruments and implants. These parts require high precision and good biocompatibility, and these requirements can be met through five-axis CNC machining technology.

V. Future Development Trends of 5-axis CNC machining parts

Technological innovation: With the continuous development of science and technology, five-axis CNC machining technology will continue to innovate and improve. For example, by introducing more advanced sensors and control systems, more precise processing control and higher production efficiency can be achieved.

Intelligent development: In the future, five-axis CNC machining technology will develop in the direction of intelligence. By introducing artificial intelligence and machine learning technologies, the automation and optimization of the processing process can be realized, further improving production efficiency and product quality.

Green manufacturing: With the increasing global attention to environmental protection and sustainable development, five-axis CNC machining technology will develop in the direction of green manufacturing. Through measures such as optimizing processing paths and tool trajectories, reducing material waste and energy consumption, a more environmentally friendly and sustainable production method can be achieved.

VI. Common Problems of 5-axis CNC machining parts

In the process of five-axis CNC machining parts, some problems are often encountered, which may stem from multiple aspects such as equipment, process, materials or operations. The following are some common problems and their solutions:

Decline in machine tool accuracy

Problem description: After long-term use of the machine tool, the accuracy of the machine tool may decline, resulting in large dimensional deviations of the machined parts.

Solution: Regularly maintain and calibrate the machine tool, check and adjust the geometric accuracy and positioning accuracy of the machine tool. At the same time, pay attention to maintaining a stable working environment and temperature of the machine tool to avoid the influence of temperature changes on the accuracy of the machine tool.

Excessive tool wear

Problem description: In the five-axis CNC machining process, the tool wears out quickly, resulting in reduced processing efficiency and decreased surface quality of the parts.

Solution: Select tools suitable for the processing materials and process requirements, optimize the tool path and cutting parameters to reduce tool wear. At the same time, regularly inspect and replace the tools to ensure the sharpness and durability of the tools.

Workpiece deformation

Problem description: During the processing, due to factors such as cutting force and thermal deformation, the workpiece may have deformation problems.

Solution: Optimize the processing technology and clamping method to reduce the influence of cutting force and thermal deformation on the workpiece. At the same time, fully preheat and cool the workpiece to reduce thermal deformation during the processing.

Programming errors

Problem description: In five-axis CNC machining, programming errors may lead to incorrect processing paths, tool collisions and other problems.

Solution: Strengthen the training and management of programmers to improve the accuracy and reliability of programming. At the same time, use simulation software to simulate and verify the processing process, and discover and correct programming errors in a timely manner.

Servo system failure

Problem description: The servo system, as an important component of the five-axis CNC machine tool, its failure may cause the machine tool to not work properly.

Solution: Regularly maintain and inspect the servo system to ensure its normal operation. At the same time, strengthen the diagnosis and maintenance capabilities of servo system failures to be able to troubleshoot in a timely manner when failures occur.

Five-axis CNC machining technology, as an important part of modern manufacturing, plays an increasingly important role in the field of parts manufacturing with its characteristics of high precision, high efficiency and high flexibility. Through detailed analysis of the principle, process and application cases of five-axis CNC machining technology in fields such as automobiles, aerospace and medical devices, this article reveals the significant advantages of 5-axis CNC machining parts in improving production efficiency, reducing production costs and enhancing product quality. In the future, with the continuous technological innovation and the development trends of intelligence and greening, the application prospects of 5-axis CNC machining parts will be even broader.