Introduction: What Are Custom CNC Bearing Parts?

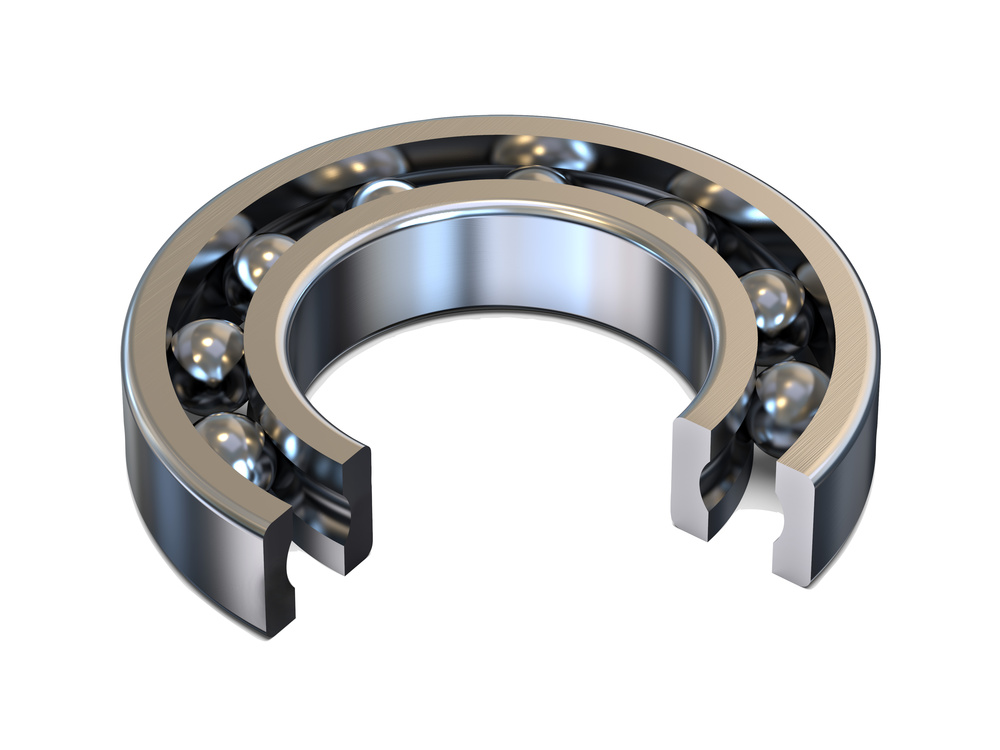

If you’ve ever worked with industrial machinery, you know that bearings are the unsung heroes keeping everything running smoothly. These small but critical components reduce friction between moving parts, ensuring precision operation and extending equipment lifespan. But when standard off-the-shelf bearings don’t meet your specific requirements, custom CNC bearing parts become essential.

At XiamenGoldCattle, we’ve been perfecting the art of CNC bearing machining for over 26 years. As a national high-tech enterprise, we understand that every application has unique demands that standard bearings can’t always satisfy. That’s where our custom CNC machining expertise comes in.

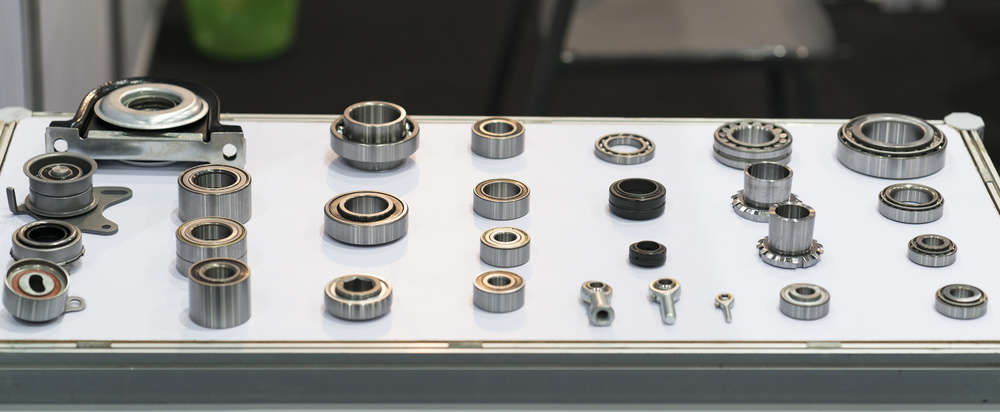

What Types of CNC Bearing Parts Can Be Customized?

Bearing Outer Rings

The outer ring forms the housing for the bearing assembly. We machine outer rings with precise roundness, concentricity, and surface finish to ensure proper fit and rotation.

Bearing Inner Rings

Inner rings require even tighter tolerances since they directly interface with shafts. Our CNC turning centers achieve the high precision needed for proper shaft engagement.

Bearing Housings / Seats

These critical components position and secure bearings within machinery. We customize bearing housings for OEM equipment across various industries.

Bearing Cages / Retainers

Cages maintain proper spacing between rolling elements. Our CNC milling capabilities create intricate cage designs for optimal performance.

Bearing Rollers / Balls

For specialized applications, we manufacture custom rolling elements with precise dimensions and surface treatments.

Miniature Bearing Parts

Our micro-machining capabilities produce tiny bearing components for medical devices, aerospace, and precision instruments.

Materials for CNC Bearing Parts

Stainless Steel (440C / 304 / 316L)

- 440C: Offers excellent hardness and wear resistance after heat treatment

- 304: Good corrosion resistance for general applications

- 316L: Superior corrosion resistance for marine and medical environments

Chrome Steel / Alloy Steel (GCr15)

The industry standard for high-performance bearings, offering excellent fatigue life and wear resistance.

Aluminum 6061 / 7075

Lightweight options for applications where weight reduction is critical, such as aerospace components.

Brass / Bronze

Natural lubricity makes these ideal for low-speed, high-load applications where maintenance access is limited.

Titanium

Offers exceptional strength-to-weight ratio and corrosion resistance for demanding environments.

Engineering Plastics (PEEK / Delrin)

For applications requiring corrosion resistance, electrical insulation, or chemical compatibility.

CNC Machining Processes Used for Bearing Parts

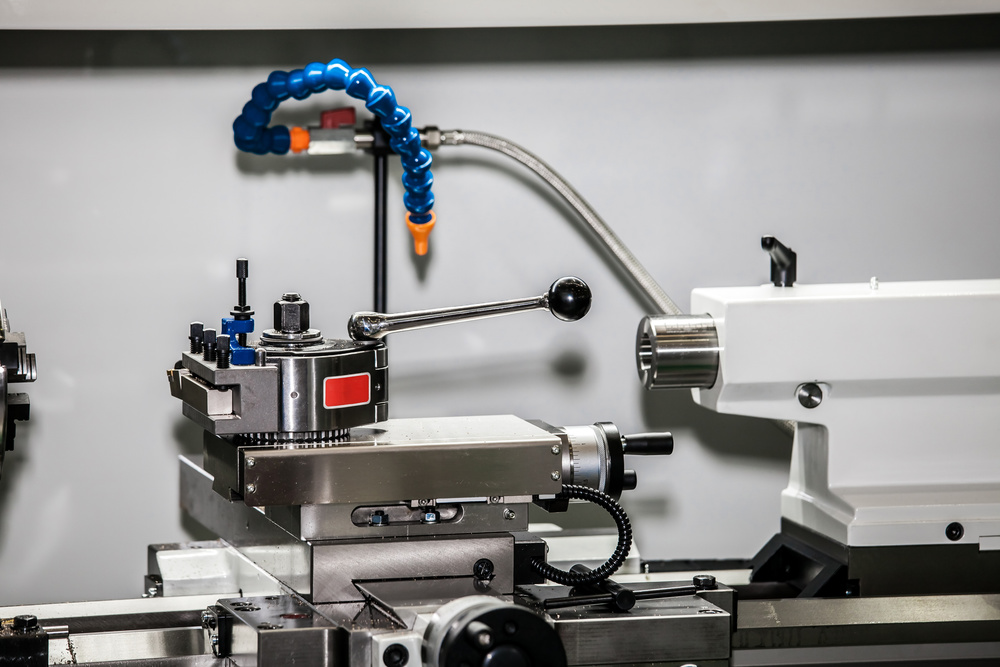

CNC Turning

Our high-precision CNC lathes achieve the concentricity and roundness critical for bearing raceways. We use live tooling to add features like slots, holes, and threads in a single setup.

CNC Milling

For bearing housings and cages, our 3-axis and 4-axis mills create complex geometries with tight tolerances.

Multi-axis Machining

Our 5-axis machining centers allow us to produce complex bearing components with fewer setups, improving accuracy and efficiency.

Precision Grinding

Achieving surface finishes down to Ra 0.1μm for bearing raceways and critical surfaces.

Heat Treatment & Hardening

We partner with certified heat treatment facilities to ensure proper material properties for bearing applications.

Surface Treatment

Options include:

- Electroplating (chrome, nickel, zinc)

- Passivation for stainless steel

- Phosphating for improved lubrication

- PTFE coating for self-lubrication

Precision & Quality Control for Bearing Part Machining

Tolerance Control Capabilities

- Standard tolerances: ±0.005mm

- Precision tolerances: ±0.002mm available for critical applications

- Roundness: Within 0.001mm for bearing raceways

Advanced Inspection Equipment

- Coordinate Measuring Machines (CMM) for 3D dimensional analysis

- Roundness testers for bearing raceway precision

- Surface roughness testers

- Hardness testing equipment

Comprehensive Quality Documentation

- Material certificates with full traceability

- First Article Inspection (FAI) reports

- Statistical Process Control (SPC) data

- ISO 9001:2015 certified quality management system

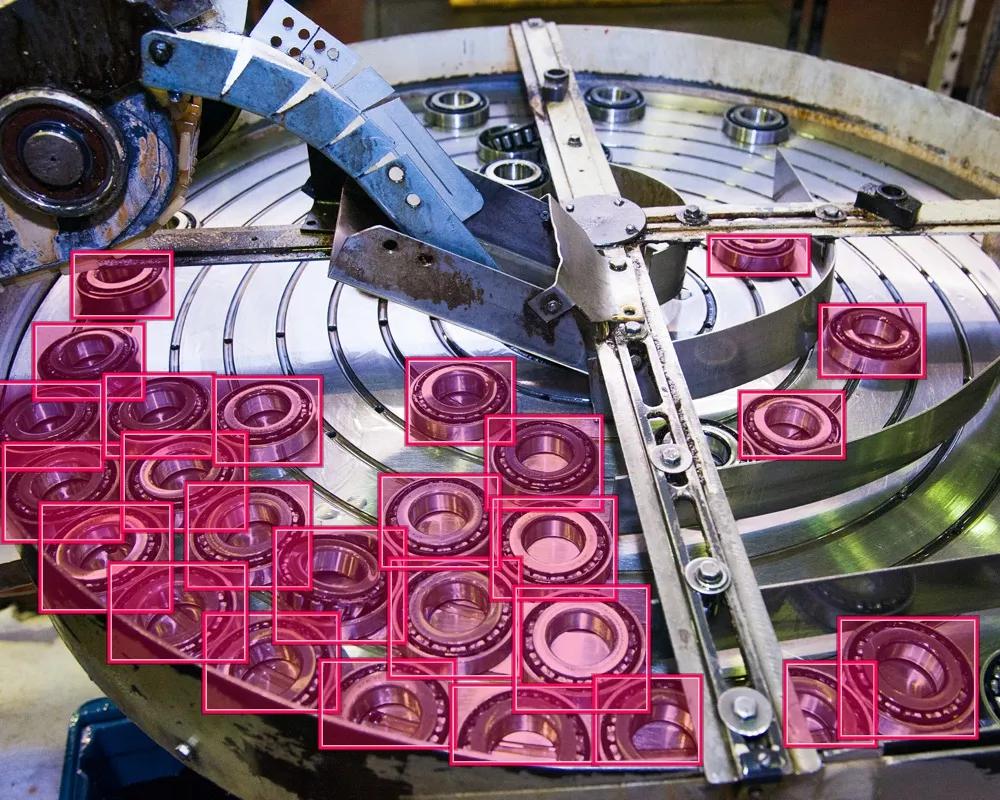

Production Tracking System

Each batch is assigned a unique tracking number for complete traceability from raw material to finished product.

Customization Options

We offer complete customization to meet your specific requirements:

Material Selection: Choose from our extensive range of bearing materials based on your application needs.

Dimensional Customization: From standard sizes to completely unique designs, we match your exact specifications.

Surface Treatment Options: Select the optimal finish for your application’s environment and performance requirements.

Complete Bearing Assemblies: We can supply fully assembled bearing units with all components ready for installation.

OEM Design Support: Our engineering team can assist with design optimization for manufacturability and performance.

Lead Time & Manufacturing Capacity

Rapid Prototyping

- Sample production: 3-7 days

- Quick-turn prototypes available for urgent projects

- Design verification and testing support

Mass Production Capacity

- Multiple CNC machining centers operating 24/7

- Automated production cells for high-volume runs

- Flexible manufacturing to handle varying batch sizes

Global Shipping & Logistics

- Partnered with UPS, DHL, and FEDEX for reliable international delivery

- Custom packaging solutions to ensure part protection during transit

- Door-to-door service available worldwide

How We Ensure Competitive Pricing for Bearing Parts

We understand that cost is an important factor in your decision-making process. Here’s how we deliver competitive pricing:

Automated Production: Our advanced CNC equipment reduces labor costs while improving consistency.

Process Optimization: Combining multiple operations into single setups reduces production time.

Material Efficiency: Computer-aided nesting and optimized cutting paths minimize material waste.

Supply Chain Strength: Long-term relationships with material suppliers ensure stable pricing.

Value Engineering: Our engineers suggest design modifications that reduce manufacturing costs without compromising performance.

How to Request a Quote

Getting a quote for your custom CNC bearing parts is simple:

1. Design Submission:

- 3D models (STEP, IGES, STL)

- 2D drawings with dimensions and tolerances

- Quantity requirements (prototyping or production)

2. Application Details:

- Operating environment (temperature, humidity, contaminants)

- Load and speed requirements

- Any special certifications needed

3. Timeline:

We typically provide quotes within 24 hours of receiving complete information. For complex designs, our engineering team may contact you for clarification to ensure accuracy.

Conclusion: Why Choose Our Custom CNC Bearing Parts Machining Service

When it comes to custom CNC bearing parts, precision and reliability are non-negotiable. At XiamenGoldCattle, we offer:

Uncompromising Precision: With tolerances down to ±0.002mm and state-of-the-art inspection equipment, we ensure every part meets your exact specifications.

Complete Material & Process Capabilities: From standard steels to exotic alloys, and from turning to 5-axis machining, we have the capabilities to handle your most challenging bearing projects.

International Quality Standards: Our ISO 9001:2015 certification and comprehensive quality control system ensure consistent results.

Fast Turnaround: With our rapid prototyping and high-volume production capabilities, we meet your deadlines without sacrificing quality.

OEM Partnership Approach: We work closely with your engineering team to optimize designs for performance and cost-effectiveness.

With 26 years of experience and a commitment to technological innovation, XiamenGoldCattle is your trusted partner for custom CNC bearing parts. Contact us today to discuss your project requirements and experience the difference that expertise and precision can make.