At XiamenGoldCattle, we’ve learned over 26 years that standard off-the-shelf rollers often fall short of meeting the unique demands of specialized industrial applications. Every industry, from food processing to heavy manufacturing, has specific requirements that require customized solutions. That’s where CNC machining technology comes in, enabling us to produce rollers with the exact precision, materials, and performance characteristics our clients need.

Types of Custom CNC Metal Rollers We Can Machine

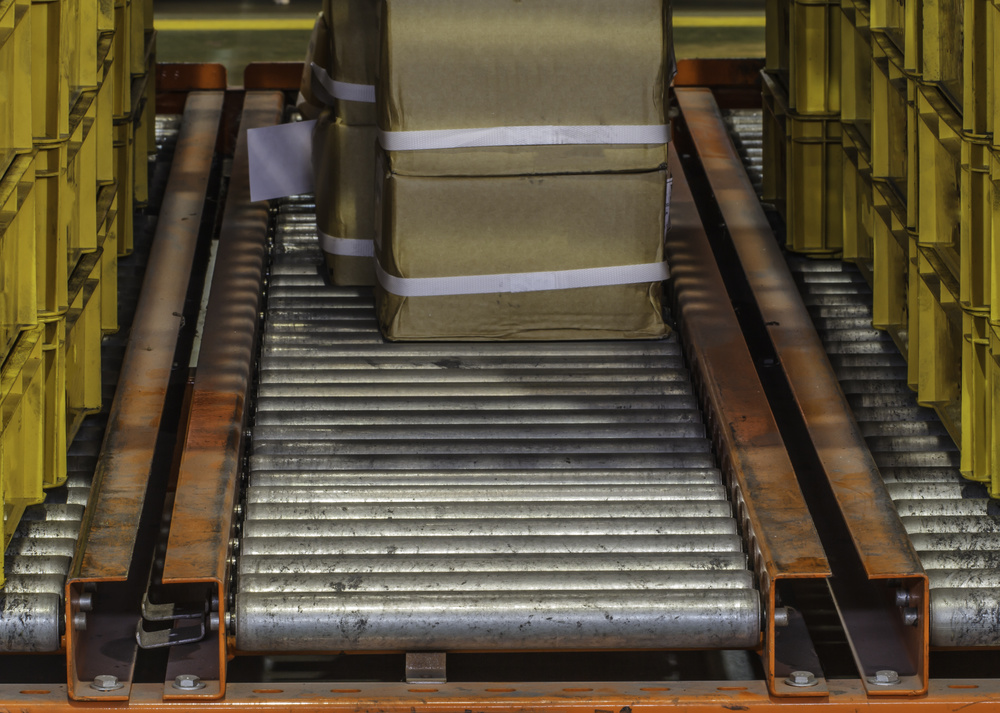

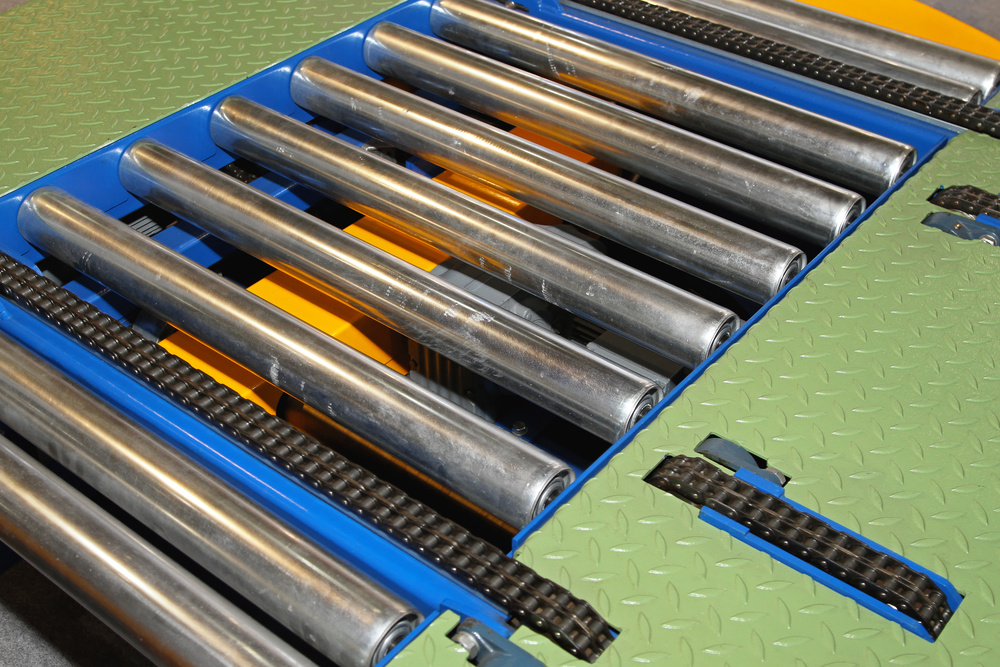

Conveyor Rollers

The backbone of any material handling system. Our CNC-machined conveyor rollers ensure smooth, reliable operation even in the most demanding environments. We customize everything from diameter and length to bearing type and surface treatment.

Guide Rollers

Precision is paramount when it comes to guiding materials through production processes. Our guide rollers are manufactured with tight tolerances to ensure accurate alignment and minimal wear.

Press & Pinch Rollers

Designed to apply controlled pressure during manufacturing processes, these rollers require special attention to surface hardness and dimensional stability.

Printing & Packaging Rollers

The printing and packaging industries demand rollers with exceptional surface finish and concentricity. Our CNC grinding capabilities ensure consistent performance even at high speeds.

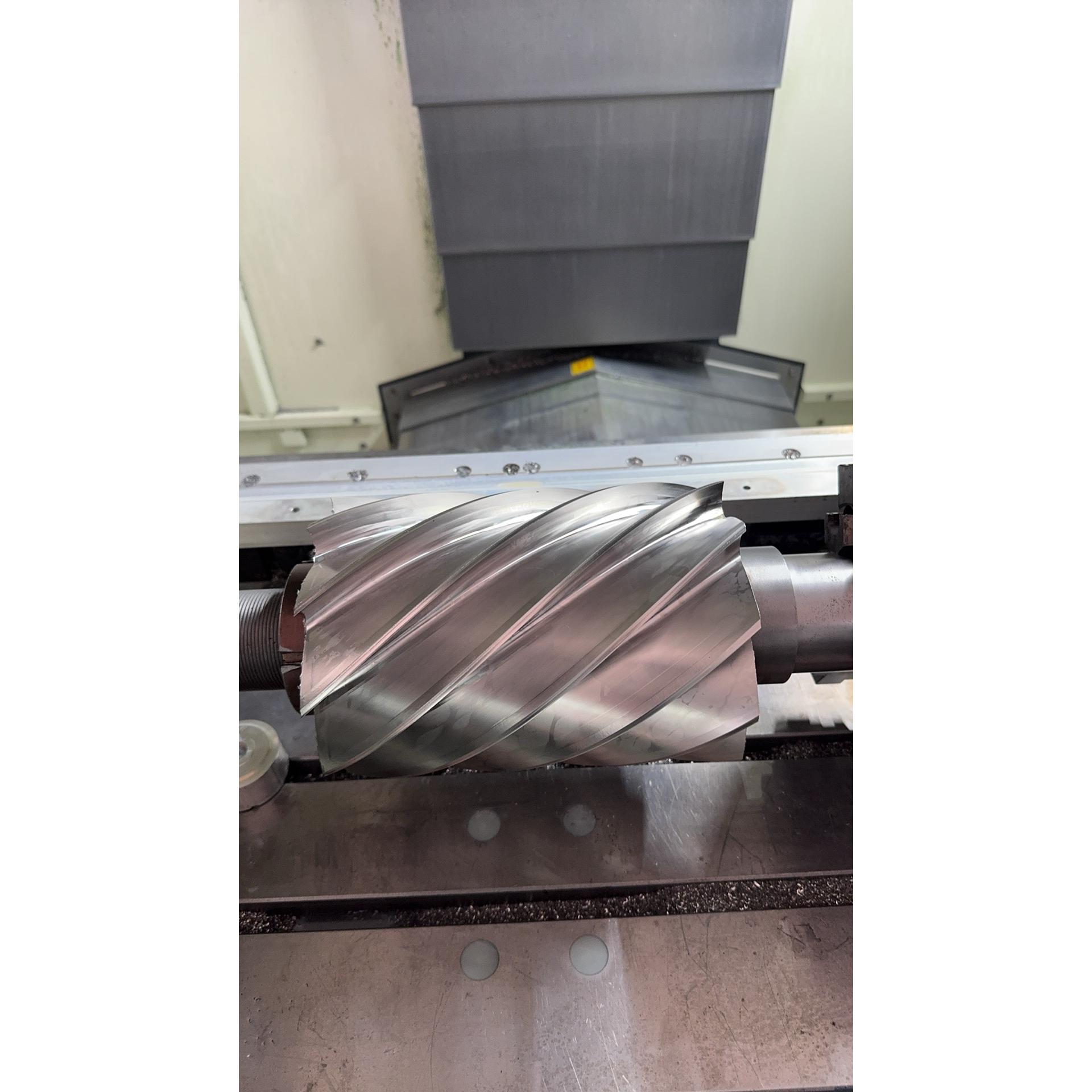

Heavy-Duty Rollers

For applications involving extreme loads or harsh conditions, we produce heavy-duty rollers using high-strength materials and reinforced designs.

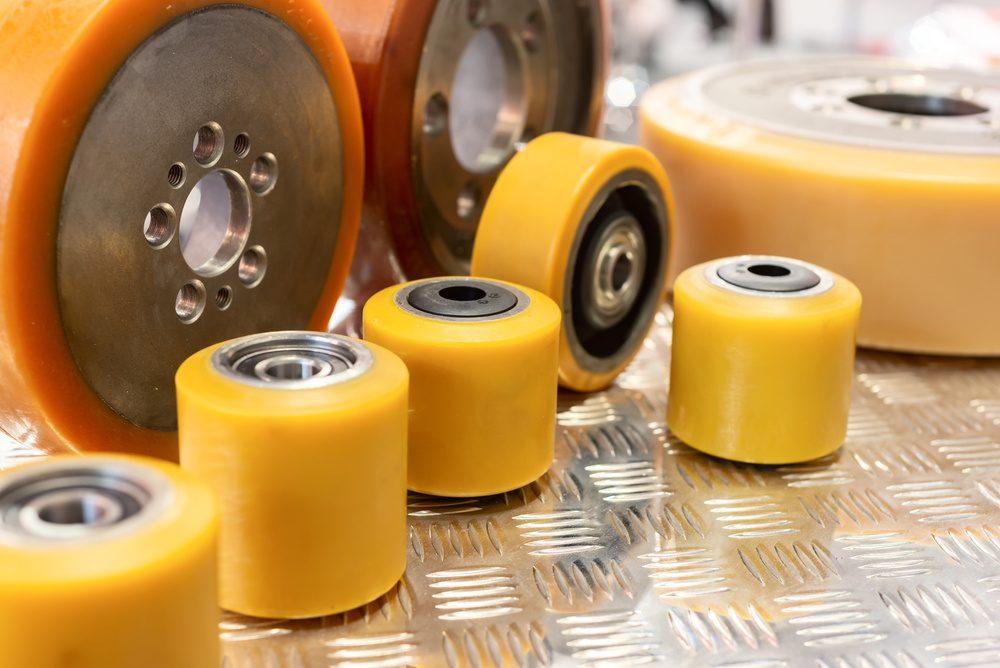

Coated Rollers

We offer a variety of coating options including PU, rubber, ceramic, and chrome plating to enhance wear resistance, reduce friction, or provide specific surface properties.

Custom OEM Rollers Based on Drawings

No matter how unique your requirements, we can bring your custom designs to life. Our engineering team works closely with clients to optimize designs for manufacturability and performance.

Materials Available for Roller Machining

Stainless Steel (304 / 316 / 420 / 440C)

- 304: Excellent corrosion resistance for general applications

- 316: Superior corrosion resistance for marine or chemical environments

- 420 & 440C: High carbon stainless steels offering excellent hardness and wear resistance after heat treatment

High-Strength Alloy Steel

For applications requiring maximum strength and durability, we use alloy steels like 4140 and 4340 that can be heat-treated to achieve specific mechanical properties.

Carbon Steel

A cost-effective option for less demanding applications where strength and durability are still important considerations.

Aluminum Alloy

When weight reduction is critical, aluminum rollers provide an excellent solution. We work with alloys like 6061 and 7075 for optimal strength-to-weight ratios.

Brass / Bronze

These materials offer natural lubricity and corrosion resistance, making them ideal for applications where maintenance access is limited or where non-magnetic properties are required.

The choice of material significantly impacts both the performance and cost of your rollers. Our experienced team can help you select the optimal material based on your specific application requirements and budget considerations.

CNC Machining Capabilities for Roller Parts

CNC Turning

Our high-precision CNC lathes achieve the concentricity and roundness critical for roller performance. We can machine rollers with diameters from 10mm up to 600mm and lengths up to 2000mm.

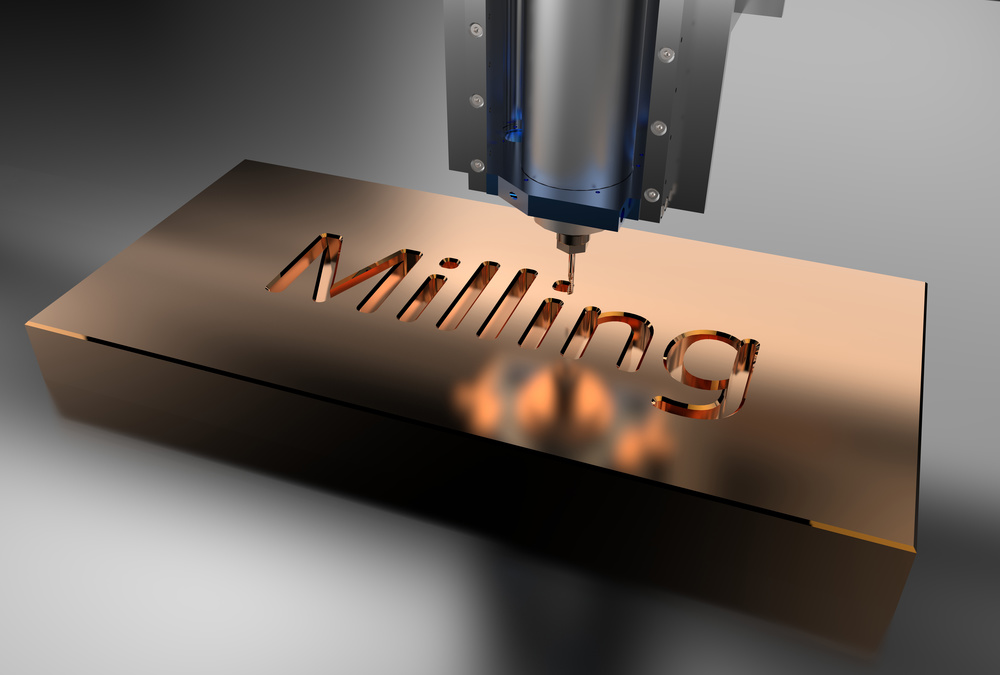

CNC Milling

For rollers requiring flats, slots, keyways, or other special features, our CNC milling centers provide the versatility needed to create complex geometries.

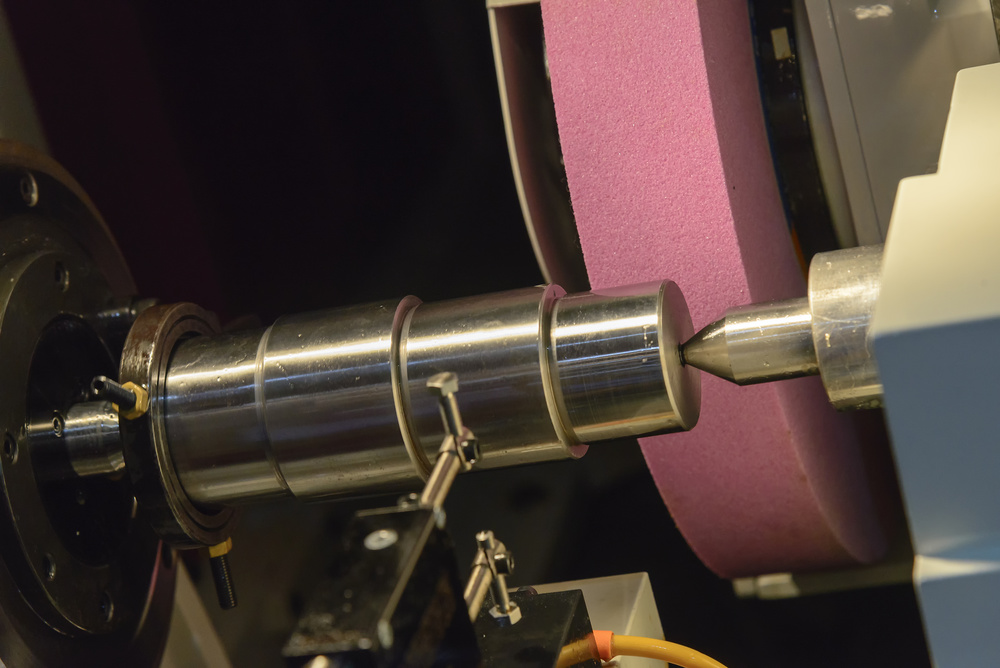

Cylindrical Grinding

The final step in achieving the perfect roller surface. Our cylindrical grinding capabilities ensure roundness within 0.001mm and surface finishes down to Ra 0.2μm.

Dynamic Balancing

Critical for high-speed applications, our dynamic balancing services ensure smooth operation and extended bearing life.

Surface Treatment

We offer a comprehensive range of surface treatments:

- Hard chrome plating for wear resistance

- Electroless nickel plating for corrosion protection

- Anodizing for aluminum rollers

- Various polishing and finishing options

- Sandblasting for specific surface textures

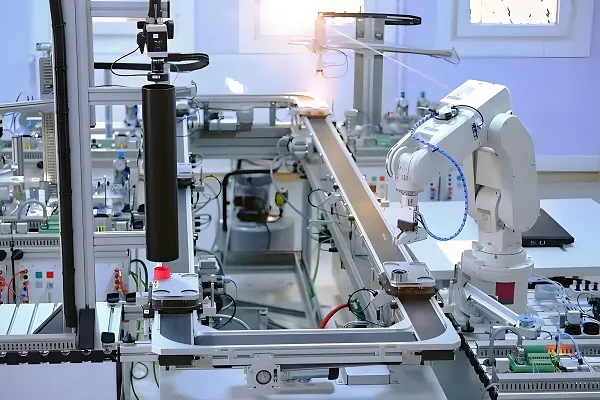

Roller Assembly

Our services extend beyond machining to include complete roller assembly, including bearing installation, shaft pressing, and final testing.

Precision & Quality Control

Tolerance Capabilities

- Roundness: Within 0.001mm

- Concentricity: Up to 0.002mm TIR (Total Indicated Runout)

- Diameter tolerances: ±0.005mm

- Length tolerances: ±0.01mm

Inspection Equipment

- Coordinate Measuring Machines (CMM) for 3D dimensional analysis

- Roundness testers for precision measurement of roller geometry

- Surface roughness testers to verify finish quality

- Hardness testing equipment to ensure material properties

Full QC Reports

Every batch of rollers comes with comprehensive quality control documentation including:

- Dimensional inspection reports

- Surface treatment verification

- Balancing reports (when applicable)

Consistency Control for High-Volume Orders

We implement statistical process control (SPC) to ensure consistent quality across large production runs. Our advanced manufacturing systems monitor key parameters in real-time to maintain process stability.

Customization Options

At XiamenGoldCattle, we understand that every application is unique. That’s why we offer extensive customization options:

Size Range: From small guide rollers (10mm diameter) to large industrial rollers (600mm diameter x 2000mm length)

Material Selection: Choose from our wide range of metals based on your specific requirements

Surface Treatment: Select the optimal finish to enhance performance and longevity

Coating Options: Various materials including rubber, polyurethane, ceramic, and metallic coatings

Structural Design Optimization: Our engineering team can suggest modifications to improve strength, reduce weight, or lower manufacturing costs while maintaining performance

Lead Time & Production Capacity

Sample Lead Time

We understand the importance of rapid prototyping in product development. Our typical lead time for samples is 3-7 days, allowing you to test and validate designs quickly.

Mass Production

Once your design is finalized, we can scale up to high-volume production with lead times typically ranging from 7-20 days depending on complexity and quantity.

Flexible Production for Small or Large Orders

Whether you need a single custom roller or thousands of identical parts, our manufacturing system is designed to handle orders of any size efficiently.

Global Shipping Options

We partner with leading logistics providers to offer reliable shipping to destinations worldwide. Our packaging is designed to protect your precision components during transit.

Cost Guide: What Affects the Price of Custom Metal Rollers?

Understanding the factors that influence roller pricing can help you make more informed decisions:

Material Cost: Premium materials like stainless steel and titanium cost more than carbon steel but offer superior performance.

Dimensions: Larger rollers require more material and machining time, increasing costs. Wall thickness also affects both material usage and manufacturing complexity.

Surface Treatment: Specialized coatings and finishes add to the overall cost but can significantly extend service life.

Grinding Requirements: Higher precision grinding for tighter tolerances and better surface finish increases production time and costs.

Balancing Needs: Dynamic balancing adds cost but is essential for high-speed applications.

Order Quantity: Economies of scale apply – larger production runs typically result in lower unit costs.

Our sales engineers work closely with clients to find the optimal balance between performance requirements and budget constraints.

How to Request a Quote

Getting a quote for your custom CNC metal rollers is straightforward:

1. Design Documentation:

- Provide 2D drawings or 3D models (preferred formats: STEP, IGES, DWG)

- Include all critical dimensions and tolerances

- Specify material requirements and quantities

2. Application Details:

- Describe how the roller will be used

- Include operating conditions (temperature, speed, load)

- Specify any special requirements or standards that must be met

3. Timeline:

- Let us know your project schedule

- Indicate if you need samples for testing

We typically provide quotes within 24 hours of receiving complete information. For complex designs, our engineering team may contact you to discuss optimization opportunities.

Conclusion: Why Work With Us for Custom CNC Metal Roller Parts

When it comes to custom CNC metal rollers, precision and reliability are non-negotiable. At XiamenGoldCattle, we offer:

Uncompromising Precision: With over 26 years of experience and state-of-the-art equipment, we consistently achieve tolerances that exceed industry standards.

Comprehensive Capabilities: From material selection to final assembly, we provide end-to-end solutions for all your roller needs.

Industry Expertise: Our team has extensive experience serving a wide range of industries, giving us valuable insights into application-specific requirements.

Quality Assurance: Our ISO 9001:2015 certified quality management system ensures consistent results on every project.

Responsive Service: We understand that time is critical in manufacturing. Our team is committed to providing prompt quotes and meeting delivery deadlines.

OEM/ODM Support: We work closely with equipment manufacturers to develop custom roller solutions that integrate seamlessly with their products.

Whether you’re looking for a single prototype or high-volume production, XiamenGoldCattle has the expertise and capabilities to meet your custom CNC metal roller needs. Contact us today to discuss your project and discover how our precision machining services can enhance your manufacturing processes.