1. What are Precision CNC Mechanical Parts?

Precision CNC mechanical parts refer to high-precision mechanical components manufactured through Computer Numerical Control (CNC) technology, which can achieve micron-level machining accuracy and process complex geometric shapes.

Advantages of Precision CNC Mechanical Parts

- Ultra-high machining accuracy: It can achieve a machining tolerance of ±0.01-0.05mm, meeting the strict requirements of high-end manufacturing fields.

- Automated machining: The machining process is completed automatically through pre-written programs, reducing manual intervention and errors.

- Strong flexibility: It can quickly switch between machining tasks of different parts, suitable for small-batch and multi-variety production.

- Ability to machine complex parts: It can machine complex curved surfaces and spatial structures that are difficult to achieve with traditional methods.

- High quality stability: The standardized machining process ensures the consistent quality of each part.

2. Why Customize Mechanical Parts?

Advantages of Customized Mechanical Parts

- Meet personalized needs: Customize size, shape, material and function according to customers’ specific requirements.

- Improve product quality: Adopt advanced machining equipment and technology to ensure the precision and performance of parts.

- Optimize cost structure: Produce on demand to avoid inventory backlog and resource waste.

- Shorten development cycle: Respond quickly to market demands and accelerate the time to market of products.

- Support technological innovation: Realize the application of complex designs and new technologies.

- Enhance enterprise competitiveness: Provide differentiated products to improve market position.

3. Customization Process of CNC Mechanical Parts

- Demand communication: Conduct in-depth communication with customers to clarify the function, performance and usage requirements of parts.

- Scheme design: Design parts according to needs and formulate machining process plans.

- Drawing confirmation: Provide detailed engineering drawings and confirm design details with customers.

- Material selection: Select appropriate machining materials according to the requirements of parts.

- Quotation confirmation: Provide a detailed quotation and confirm order information.

- Machining production: Arrange CNC machining equipment for parts manufacturing.

- Quality inspection: Conduct comprehensive quality inspection on the machined parts.

- Delivery and acceptance: Package and ship the parts, and customers confirm the acceptance.

4. Machining Process of CNC Mechanical Parts

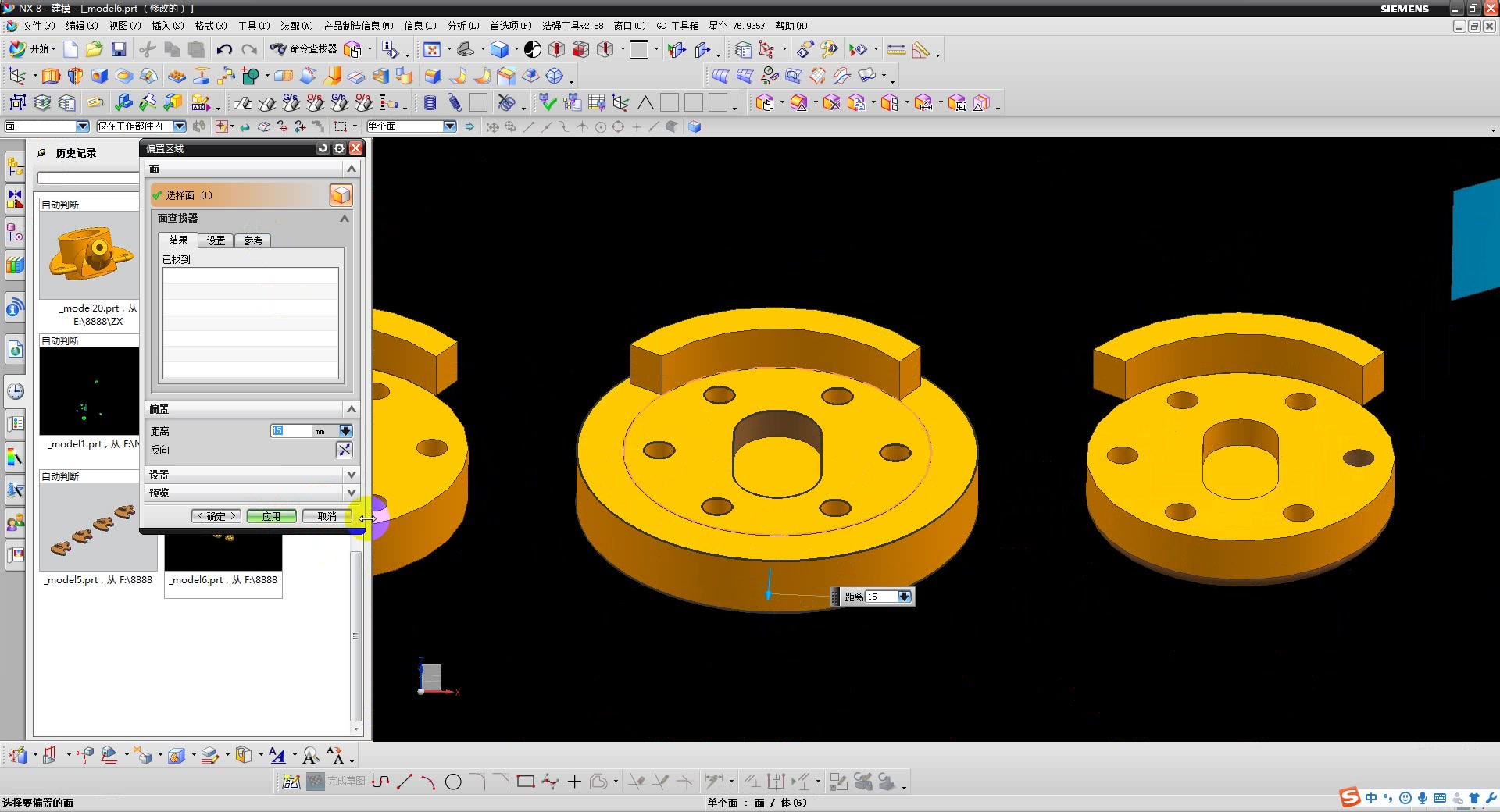

- Parts design: Use CAD software to design 3D models and generate engineering drawings.

- Process planning: Formulate the machining process route and determine the machining sequence and methods.

- CNC programming: Use CAM software to convert the design into G-code recognizable by the machine tool.

- Material preparation: Select appropriate materials and carry out blanking and preprocessing.

- Machine tool setup: Install cutters and fixtures, and calibrate machine tool parameters.

- Machining operation: Start the machine tool and carry out automatic machining according to the program.

- Quality inspection: Use precision testing equipment to check the size and quality of parts.

- Post-processing: Conduct deburring, surface treatment and other subsequent processing.

- Packaging and delivery: Protect the parts through packaging and deliver them to customers.

5. Machinable Material List for CNC Mechanical Parts

|

Material Category

|

Common Materials

|

Characteristics

|

Application Fields

|

|

Aluminum Alloy

|

6061, 7075

|

Lightweight, corrosion-resistant, easy to machine

|

Aerospace, automobile, electronics

|

|

Stainless Steel

|

304, 316

|

Strong corrosion resistance, high strength

|

Medical equipment, food industry

|

|

Titanium Alloy

|

TC4, TA2

|

High strength, low density, corrosion-resistant

|

Aerospace, medical equipment

|

|

Carbon Steel

|

45# Steel, 40Cr

|

High strength, low cost

|

Mechanical equipment, automobile manufacturing

|

|

Copper Alloy

|

Brass, Red Copper

|

Good electrical conductivity, strong thermal conductivity

|

Electronics, communication equipment

|

|

Engineering Plastics

|

ABS, PC, PEEK

|

Lightweight, corrosion-resistant

|

Electronic equipment, medical equipment

|

|

Composite Materials

|

Carbon Fiber, Glass Fiber

|

High strength, low density

|

Aerospace, sports equipment

|

6. Attribute List of CNC Mechanical Parts

|

Attribute Item

|

Technical Parameters

|

Description

|

|

Machining Precision

|

±0.01-0.05mm

|

Range of dimensional tolerance control

|

|

Surface Roughness

|

Ra0.1-3.2μm

|

Level of surface finish

|

|

Machining Materials

|

Metals, plastics, composite materials

|

Support machining of multiple materials

|

|

Part Size

|

Minimum 0.1mm, Maximum 2000mm

|

Range of machinable part sizes

|

|

Machining Equipment

|

3-axis, 4-axis, 5-axis machining centers

|

Machining needs of different complexities

|

|

Machining Efficiency

|

1-1000 pieces/day

|

Range of production capacity

|

|

Delivery Cycle

|

1-15 working days

|

Time from order placement to delivery

|

|

Quality Certification

|

ISO9001, IATF16949

|

Quality management system certification

|

7. Applications of Mechanical Parts

- Aerospace: Aircraft engine parts, airframe structural parts, landing gear components.

- Automobile Manufacturing: Engine blocks, gearbox housings, suspension system parts.

- Medical Equipment: Surgical instruments, artificial joints, medical equipment housings.

- Electronic Equipment: Mobile phone housings, heat sinks, connectors, precision components.

- Mold Manufacturing: Injection molds, die-casting molds, stamping molds.

- Energy Industry: Wind turbine parts, oil drilling equipment components.

- Military Equipment: Weapon system parts, armored vehicle components.

- Industrial Automation: Robot parts, automation equipment accessories.

8. Machining Issues of CNC Mechanical Parts

Common Machining Issues and Solutions

- Causes: Machine tool errors, tool wear, programming errors, unreasonable parameter settings.

- Solutions: Conduct regular maintenance of machine tools, replace tools in a timely manner, optimize machining parameters, and strengthen quality inspection.

- Causes: Dull tools, unreasonable cutting parameters, machine tool vibration, insufficient cooling.

- Solutions: Use sharp tools, optimize cutting parameters, enhance machine tool rigidity, and use cooling fluid properly.

- Causes: Improper material selection, excessively high cutting parameters, insufficient cooling.

- Solutions: Select appropriate tool materials, optimize cutting parameters, and ensure sufficient cooling.

- Causes: Unreasonable program writing, conservative parameter settings, insufficient equipment performance.

- Solutions: Optimize machining programs, increase cutting parameters, and upgrade machining equipment.

- Causes: Material stress release, excessive machining heat, improper clamping.

- Solutions: Conduct stress relief treatment, optimize machining parameters, and improve clamping methods.

9. Machining Cases of CNC Mechanical Parts

- The parts are aluminum reflectors, requiring the realization of complex optical details.

- The machining precision requirement is ±0.05mm, and the surface roughness requirement is Ra0.05μm.

- 7075 aerospace aluminum is selected as the material, which needs to undergo mirror polishing treatment.

- The delivery time is urgent, requiring completion within 12 working days.

- The optical surface is composed of multiple small optical surfaces, requiring precise machining.

- The machining of fine-tooth shaped optical details is difficult.

- The surface needs to achieve mirror finish, requiring high standards for manual polishing.

- The dimensional precision requirement is strict, and large fillets are not allowed.

- Use a 5-axis high-speed machining center for high-precision machining.

- Adopt a multi-stage machining process: rough machining – semi-finish machining – finish machining – fine machining.

- Use ball-end tools with a diameter of less than 5mm, and use tools with a radius of 0.15mm for the final finish machining.

- Conduct manual polishing treatment to ensure that the optical details are not damaged.

- Perform 3D scanning and roughness measurement to ensure quality meets standards.

- Successfully completed the machining of 6 reflector cups within 12 working days.

- The precision tolerance of all parts is controlled within 0.05mm.

- The surface roughness meets the requirement of Ra0.05μm.

- Completed the trial assembly verification to ensure good coordination with other components.

- The customer is very satisfied with the product effect.

- The parts successfully passed the optical performance test.

- The professional services and quality control have been recognized by the customer.

- A long-term cooperative relationship has been established between the two parties.

10. Advantages of Online Customization of CNC Mechanical Parts

- Quick quotation: Upload drawings online to get the quotation and delivery time immediately.

- Global resources: Utilize the global manufacturing network to select the optimal machining plan.

- Transparent process: Track the order status in real time and understand the machining progress.

- Quality assurance: Standardized machining process ensures product quality.

- Flexible production: Support flexible production from small batches to large batches.

- Technical support: Professional engineers provide technical consultation and optimization suggestions.

- Cost reduction: Reduce intermediate links to lower procurement costs.

- Convenient delivery: National and global distribution, delivering goods to the door.

11. Online Customization Service of CNC Mechanical Parts on Xiamen Goldcattle

- Online instant quotation: Upload CAD drawings, and the system automatically calculates the price and delivery time.

- Professional engineer team: Experienced engineers provide technical support and process optimization.

- Advanced machining equipment: Equipped with 3-axis, 4-axis and 5-axis machining centers to meet different precision requirements.

- Strict quality control: ISO9001 quality management system ensures stable product quality.

- Rich material selection: Support the machining of multiple materials such as aluminum alloy, stainless steel and titanium alloy.

- Fast delivery service: Delivery of standard parts within 1-3 days, and delivery of complex parts within 5-15 days.

- Full-process tracking service: Real-time update of order status, and machining progress can be checked at any time.

- After-sales guarantee service: Free rework for quality problems, and provision of technical support and maintenance.