1. Problem Analysis

1.1 Roundness Error Issues

- Spindle-related causes: Radial runout, axial axial movement,and angular Swing of the spindle

- Tool issues: Worn cutting tools, incorrect tool geometry, or improper tool installation

- Workpiece factors: Material inhomogeneity, thermal expansion, or improper clamping

- Machine rigidity: Insufficient structural stiffness leading to vibration during cutting

1.2 Straightness Error Issues

- Guideway problems: Linear guide rail wear, misalignment, or manufacturing defects

- Transmission errors: Ball screw wear, backlash, or improper lubrication

- Thermal effects: Temperature-induced expansion or contraction of machine components

- Cutting forces: Excessive cutting forces causing tool deflection or workpiece deformation

1.3 Flatness Error Issues

- Machine table issues: Table surface wear, warping, or insufficient rigidity

- Clamping problems: Uneven clamping forces causing workpiece deformation

- Tool path strategies: Improper tool path planning for surface finishing

- Coolant effects: Inadequate cooling leading to thermal distortion

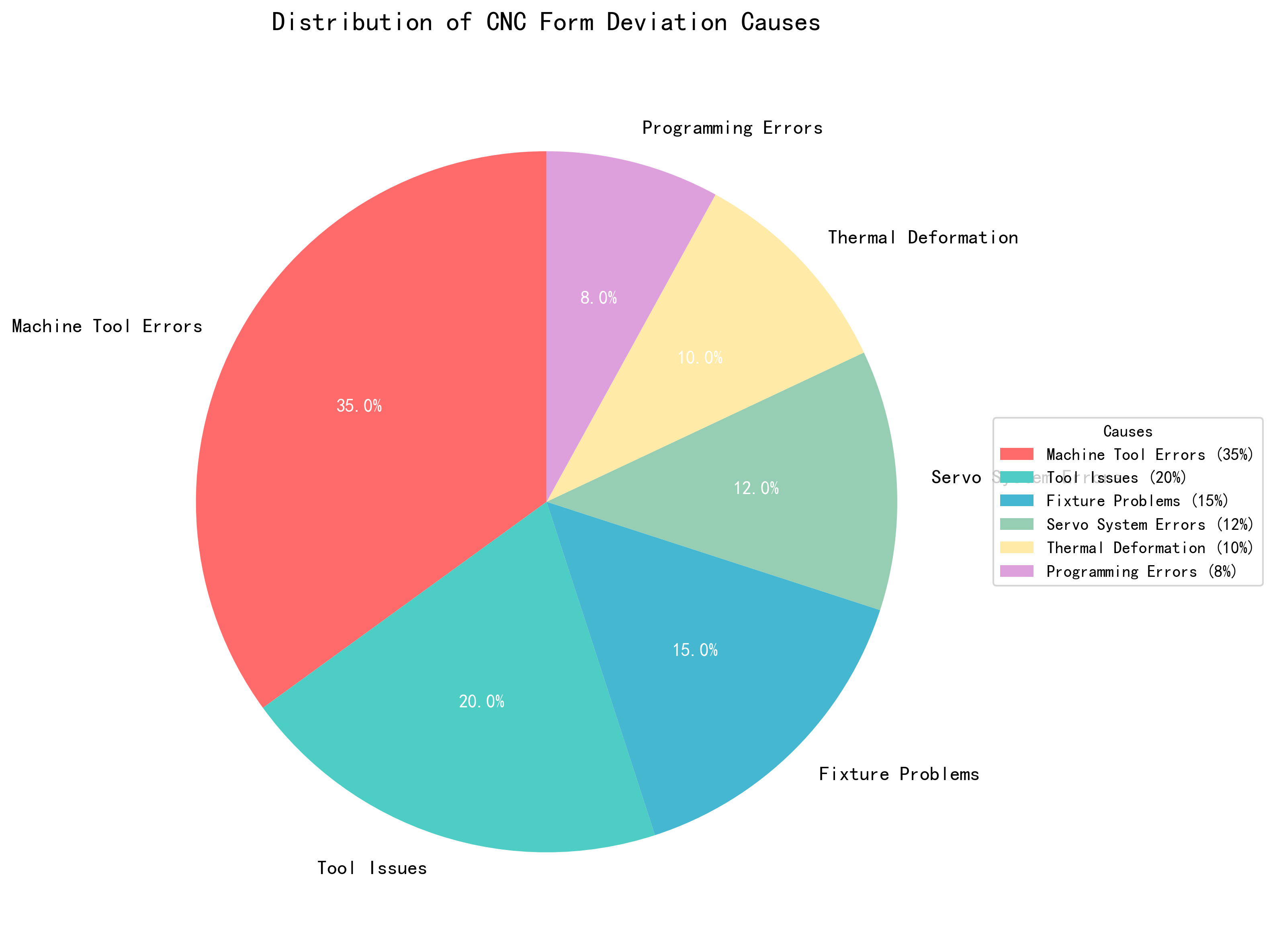

2. Root Cause Analysis

2.1 Cause Distribution Analysis

- Machine Tool Errors (35%): Most significant factor including spindle, guideway, and structural issues

- Tool Issues (20%): Tool wear, geometry, and installation problems

- Fixture Problems (15%): Clamping, positioning, and workpiece holding issues

- Servo System Errors (12%): Motion control, backlash, and parameter settings

- Thermal Deformation (10%): Temperature-induced dimensional changes

- Programming Errors (8%): Tool path planning and parameter optimization issues

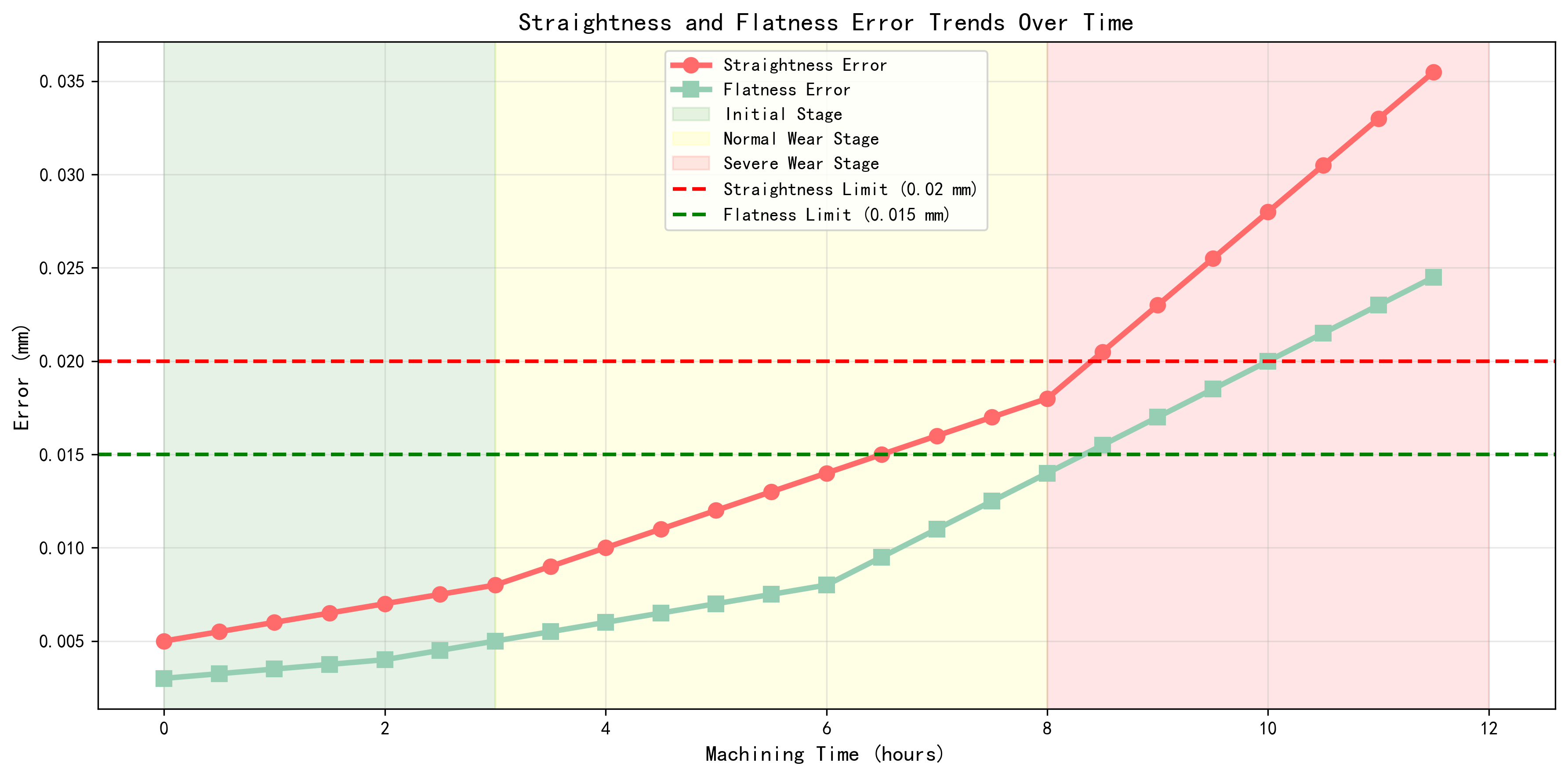

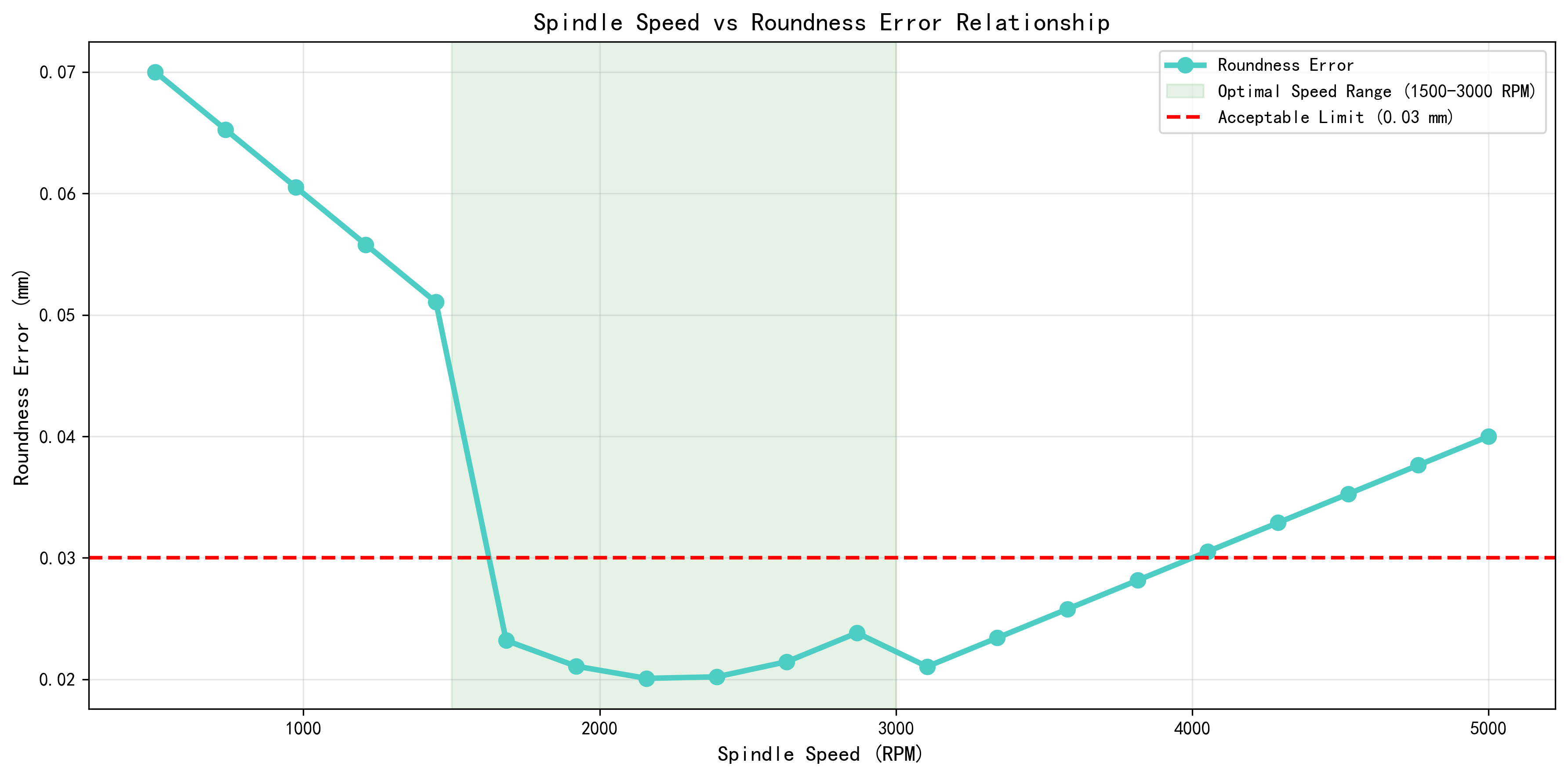

3. Error Trend Analysis

3.1 Spindle Speed vs Roundness Error Relationship

- Optimal Speed Range (1500-3000 RPM): Provides the best roundness accuracy

- Low Speed Performance (<1500 RPM): Increased error due to insufficient cutting stability

- High Speed Performance (>3000 RPM): Error increases due to spindle vibration and tool wear

- Acceptable Limit: Roundness error exceeds 0.03 mm at speeds below 1000 RPM and above 4000 RPM

3.2 Straightness and Flatness Error Trends

- Initial Stage (0-3 hours): Minimal error growth with sharp tools and stable conditions

- Normal Wear Stage (3-8 hours): Steady error increase as components begin to wear

- Severe Wear Stage (8+ hours): Accelerated error growth requiring maintenance intervention

- Tolerance Limits:

-

- Straightness error exceeds 0.02 mm after 6-7 hours

-

- Flatness error exceeds 0.015 mm after 8-9 hours

4. Solutions and Recommendations

4.1 Comprehensive Solution Framework

|

Error Type

|

Root Cause

|

Recommended Solutions

|

Implementation Priority

|

Expected Improvement

|

|

Roundness Error

|

Spindle Runout

|

Implement spindle bearing maintenance schedule, use precision bearings

|

High

|

40% reduction in roundness error

|

|

Tool Wear

|

Use coated carbide tools, implement tool life management

|

High

|

30% improvement in surface finish

|

|

|

Machine Rigidity

|

Upgrade machine foundation, use vibration damping materials

|

Medium

|

25% reduction in vibration

|

|

|

Straightness Error

|

Guideway Wear

|

Implement guideway lubrication system, 定期检查导轨精度

|

High

|

35% improvement in linear accuracy

|

|

Ball Screw Backlash

|

Install backlash compensation system, use preloaded ball screws

|

High

|

30% reduction in transmission errors

|

|

|

Thermal Effects

|

Install temperature control system, use thermal compensation

|

Medium

|

20% improvement in thermal stability

|

|

|

Flatness Error

|

Table Surface Wear

|

Resurface machine table, use precision table inserts

|

Medium

|

25% improvement in table flatness

|

|

Clamping Issues

|

Implement hydraulic clamping system, optimize clamping force

|

High

|

30% reduction in workpiece deformation

|

|

|

Tool Path Strategy

|

Use adaptive tool path planning, implement constant surface speed

|

Medium

|

20% improvement in surface quality

|

4.2 Implementation Roadmap

Phase 1: Immediate Actions (1-2 weeks)

- Implement tool inspection and replacement schedule

- Optimize spindle speed parameters based on material type

- Conduct comprehensive machine alignment check

Phase 2: Short-term Improvements (1-3 months)

- Install backlash compensation systems

- Upgrade to high-quality coated cutting tools

- Implement temperature monitoring and control

Phase 3: Long-term Solutions (3-6 months)

- Upgrade machine structural components for improved rigidity

- Implement predictive maintenance systems

- Invest in advanced metrology equipment for precision measurement

5. Expected Outcomes and Benefits

5.1 Quality Improvement Metrics

|

Metric

|

Current Performance

|

Target Performance

|

Improvement

|

|

Roundness Error

|

0.05 mm

|

0.02 mm

|

60% reduction

|

|

Straightness Error

|

0.03 mm

|

0.01 mm

|

67% improvement

|

|

Flatness Error

|

0.025 mm

|

0.01 mm

|

60% reduction

|

|

Scrap Rate

|

10%

|

3%

|

70% reduction

|

|

Rework Rate

|

15%

|

4%

|

73% reduction

|

|

Tool Life

|

8 hours

|

12 hours

|

50% improvement

|

5.2 Business Impact Analysis

- Cost Savings: 25-30% reduction in material waste and rework costs

- Productivity: 20-25% increase in machine uptime through optimized maintenance

- Quality Improvement: 50-60% reduction in geometric deviation issues

- Customer Satisfaction: Enhanced reputation for precision manufacturing

- Competitive Advantage: Ability to produce higher precision components

6. Conclusion

- Machine Maintenance: Regular inspection and calibration of critical components

- Tool Management: Implementation of tool life tracking and optimization

- Process Optimization: Development of material-specific machining strategies

- Monitoring Systems: Installation of real-time error detection and compensation

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.

The research results and technical insights shared herein are based on the author’s professional experience and experimental observations. The author and the affiliated institution shall not be liable for any direct, indirect, or consequential damages (including but not limited to equipment damage, product quality issues, or production losses) arising from the improper use of the information provided in this paper.