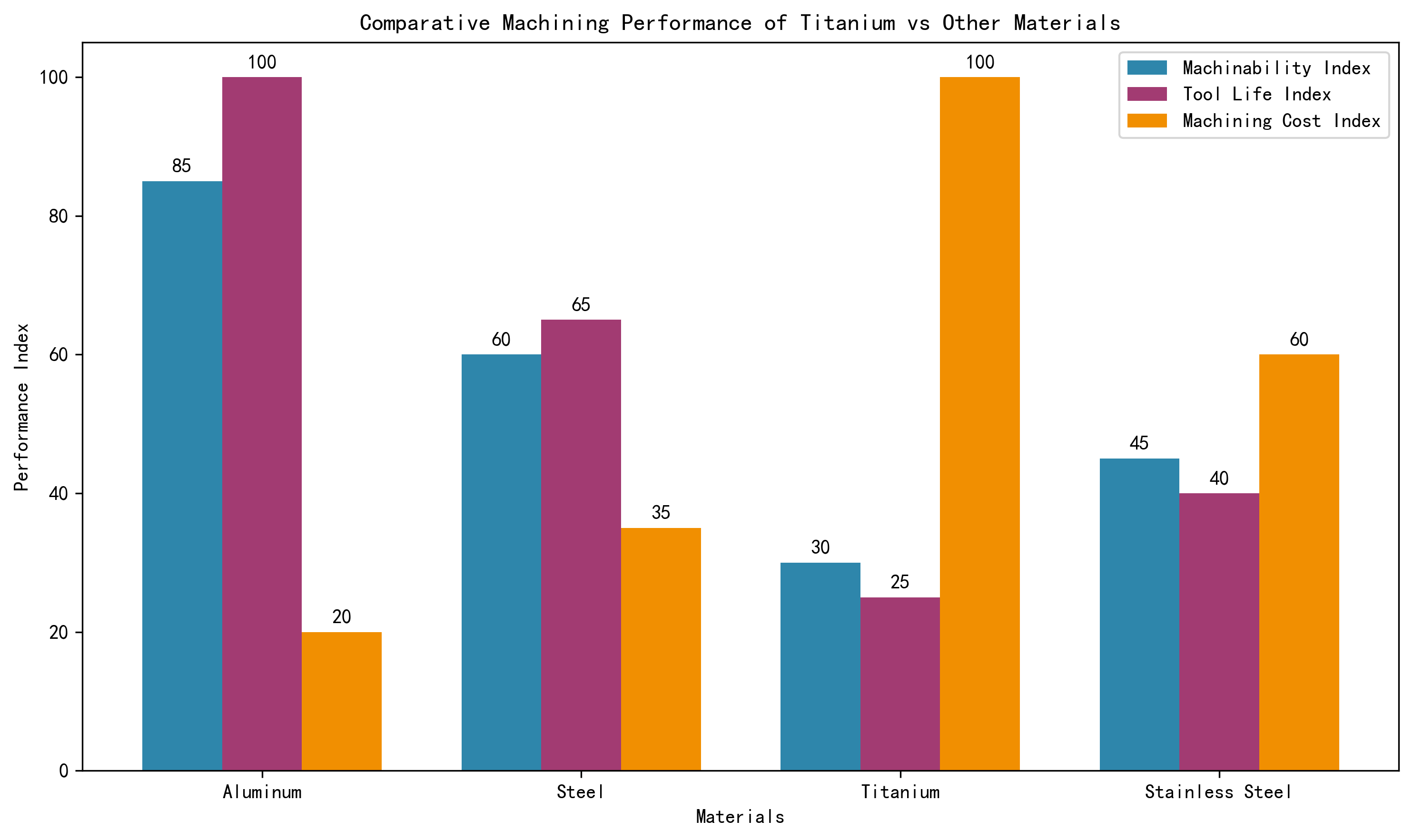

Comparative Machining Performance

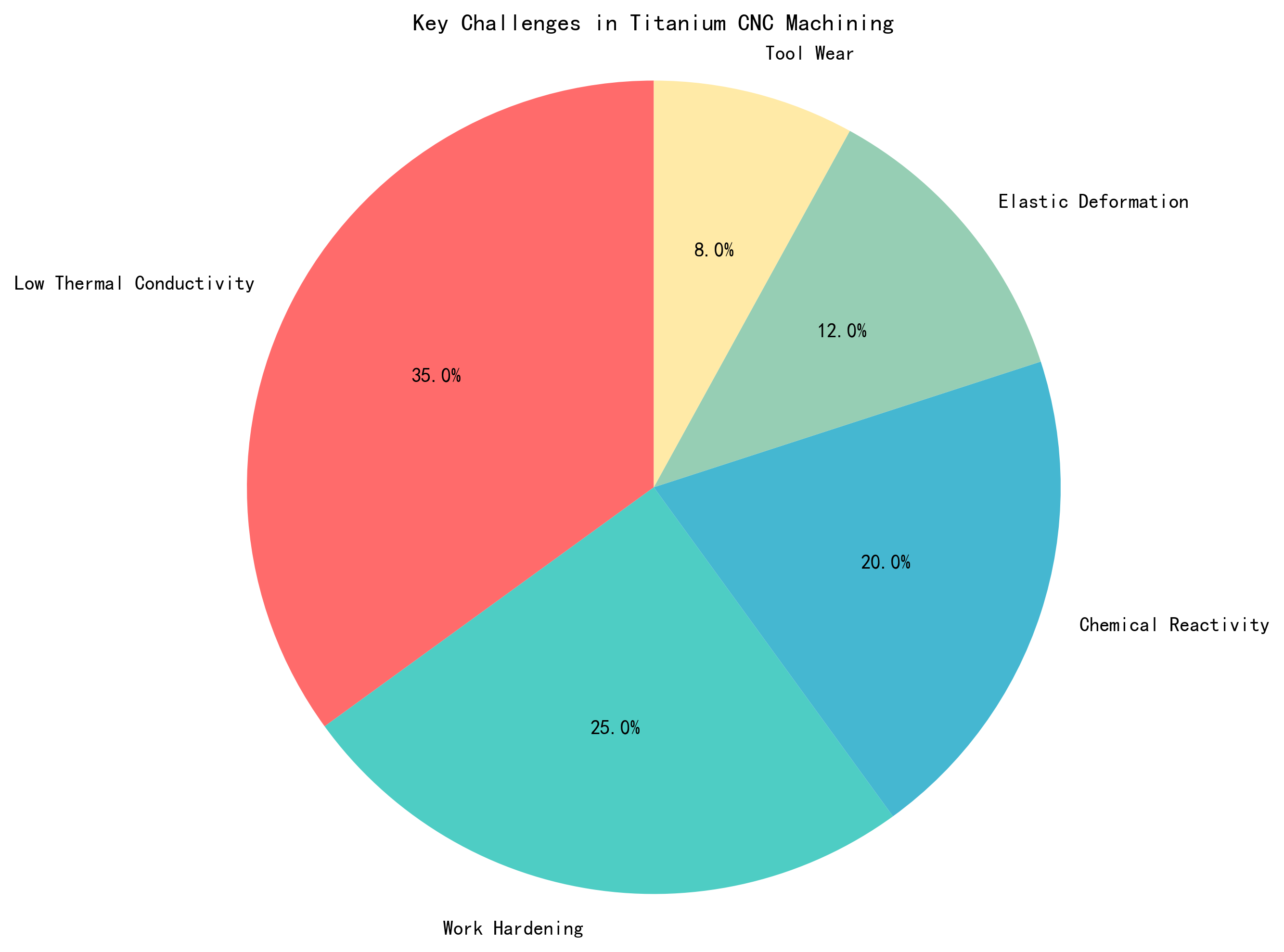

Key Challenges in Titanium Machining

- Low thermal conductivity (35%): Causes heat accumulation at cutting edge

- Work hardening (25%): Material becomes harder as it’s machined

- Chemical reactivity (20%): Reacts with cutting tools at high temperatures

- Elastic deformation (12%): Material springs back during cutting

- Tool wear (8%): Accelerated degradation of cutting tools

Titanium Grades and Machining Parameters

|

Titanium Grade

|

Tensile Strength

|

Hardness

|

Machinability

|

Recommended Cutting Speed

|

Typical Applications

|

|

Grade 1

|

240 MPa

|

120 HB

|

Good

|

40-60 m/min

|

Aerospace, Medical

|

|

Grade 2

|

344 MPa

|

142 HB

|

Moderate

|

35-55 m/min

|

Chemical processing, Marine

|

|

Grade 5 (Ti-6Al-4V)

|

950 MPa

|

330 HB

|

Poor

|

25-40 m/min

|

Aerospace, Biomedical

|

|

Grade 12

|

620 MPa

|

280 HB

|

Moderate

|

30-50 m/min

|

Chemical, Marine

|

Machining Recommendations

- Use specialized tools: Carbide or ceramic cutting tools with TiAlN coatings

- Optimize cutting parameters: Lower speeds (25-60 m/min), moderate feeds

- Implement cooling systems: High-pressure coolant delivery

- Ensure rigid setup: Minimize vibrations and chatter

- Maintain tool sharpness: Regular tool inspection and replacement

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.

The research results and technical insights shared herein are based on the author’s professional experience and experimental observations. The author and the affiliated institution shall not be liable for any direct, indirect, or consequential damages (including but not limited to equipment damage, product quality issues, or production losses) arising from the improper use of the information provided in this paper.