MIM Materials Properties

|

Material

|

Density (g/cc)

|

Tensile Strength (ksi)

|

Hardness

|

Applications

|

|

316L Stainless Steel

|

7.7

|

75

|

67 HRB

|

Medical, Consumer

|

|

17-4 PH Stainless Steel

|

7.6

|

130

|

32 HRC

|

Aerospace, Automotive

|

|

Ti-6Al-4V Titanium

|

4.4

|

120

|

35 HRC

|

Medical Implants

|

|

Low Alloy Steel

|

7.6

|

60

|

69 HRB

|

Structural

|

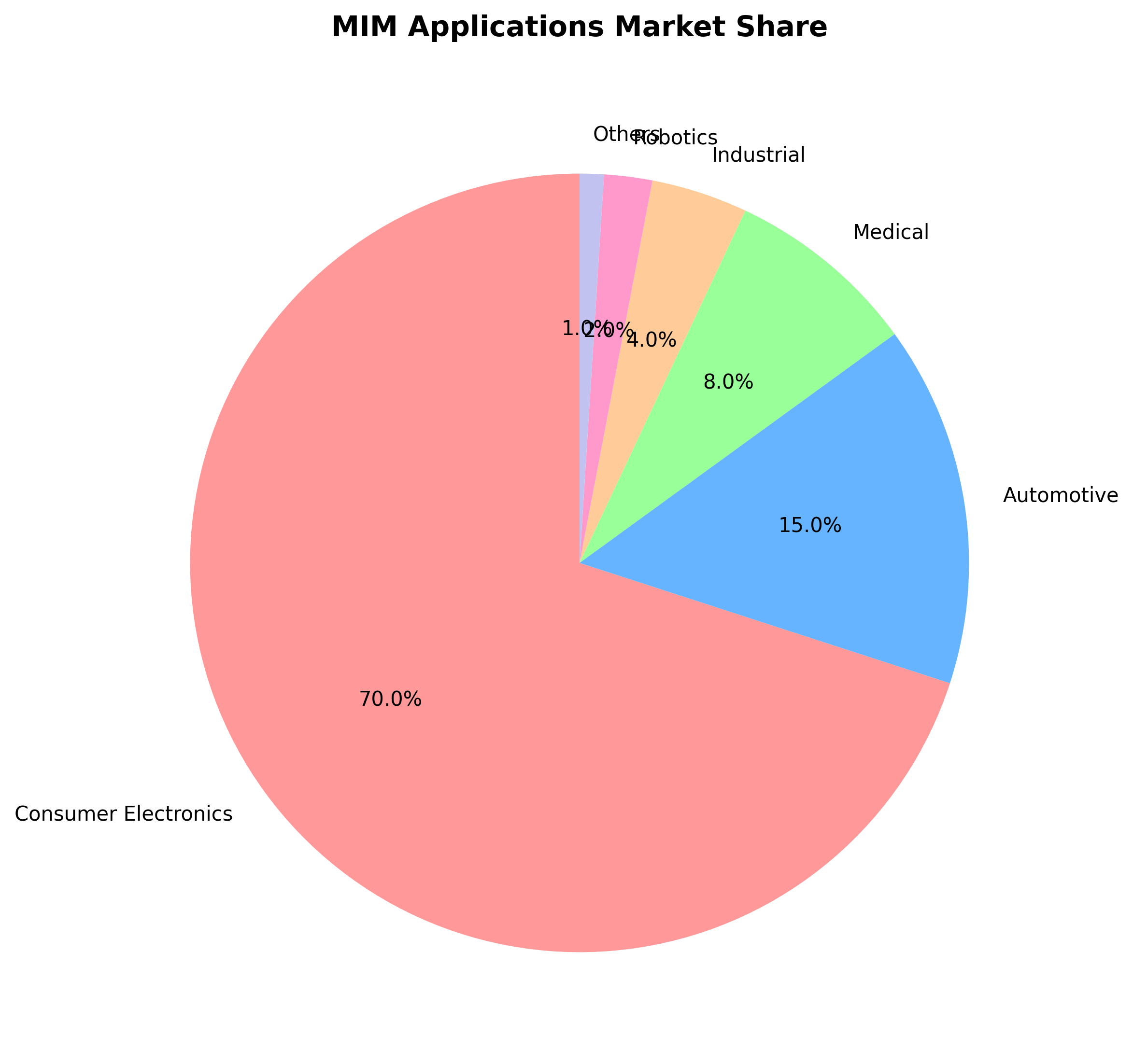

MIM Applications Market Share

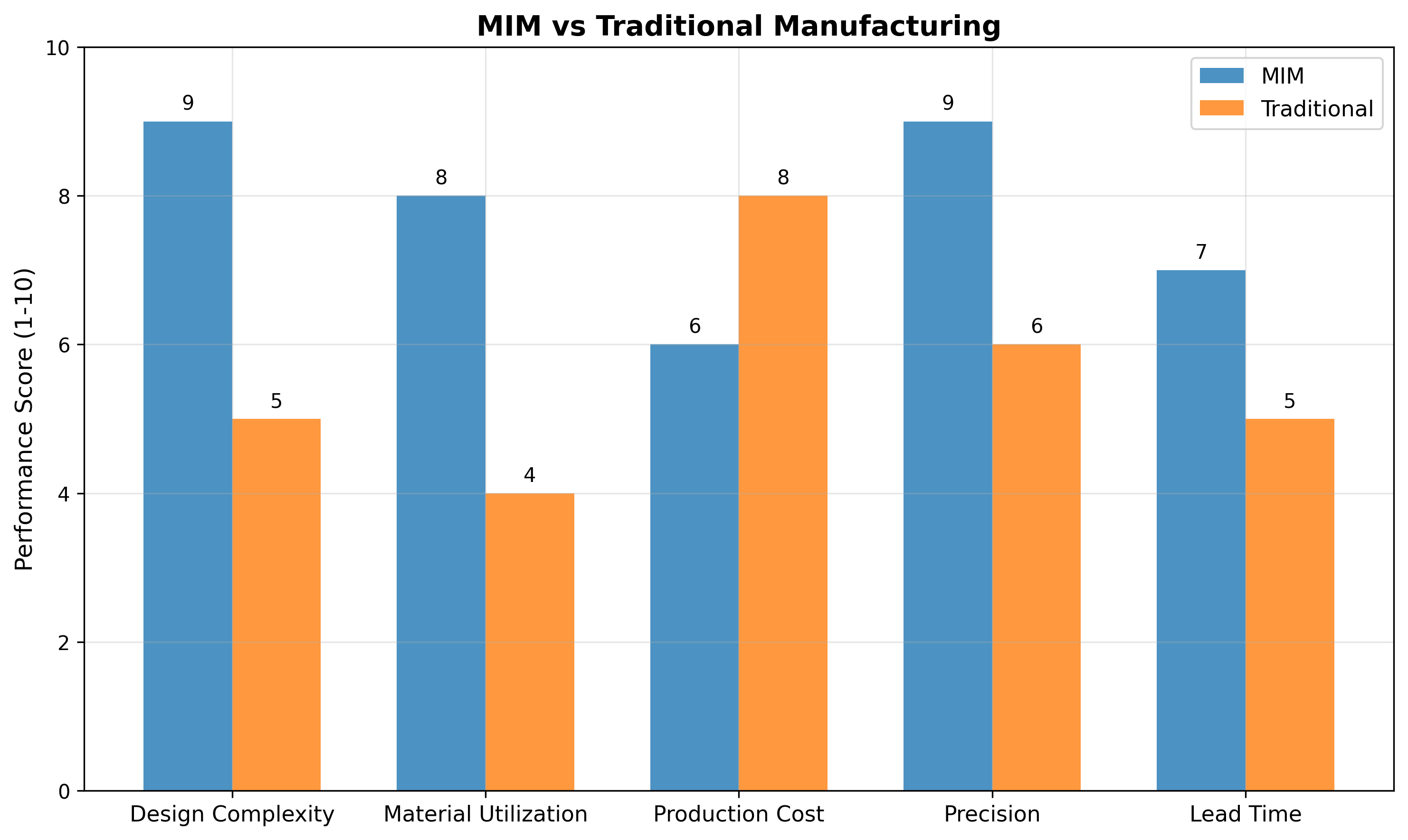

MIM vs Traditional Manufacturing

- Feedstock Preparation: Metal powders (2-25μm) mixed with binders (wax, polymer) at 60:40 ratio

- Injection Molding: Feedstock heated to 150-200°C and injected into molds at high pressure

- Debinding: Binders removed via solvent extraction, thermal decomposition, or catalytic process

- Sintering: Parts heated to 80-90% of melting temperature in controlled atmosphere

- Secondary Operations: Optional heat treatment, machining, plating, or assembly

- Powder Characteristics: Spherical shape, narrow size distribution, high purity

- Binder Systems: Thermoplastic, wax-based, or water-soluble formulations

- Critical Properties: Flowability, thermal stability, debinding efficiency

- Common Materials: Stainless steels, titanium alloys, tool steels, superalloys

- Wall Thickness: 0.2-6mm (optimal 1-3mm)

- Draft Angles: 0.5-2° for mold release

- Radii: Minimum 0.2mm internal radii

- Undercuts: Possible with split molds or collapsible cores

- Shrinkage: 12-25% linear shrinkage during sintering

- Density: 95-99% of theoretical density

- Dimensional Tolerance: ±0.3% for most dimensions

- Surface Finish: 1-3μm Ra as-sintered

- Mechanical Properties: Comparable to wrought materials

- Microstructure: Homogeneous, fine-grained structure

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.

The research results and technical insights shared herein are based on the author’s professional experience and experimental observations. The author and the affiliated institution shall not be liable for any direct, indirect, or consequential damages (including but not limited to equipment damage, product quality issues, or production losses) arising from the improper use of the information provided in this paper.