Types of Injection Molding Sticking

|

Sticking Type

|

Appearance

|

Common Causes

|

Troubleshooting Focus

|

|

Part Sticking to Cavity

|

Part adheres to cavity surface

|

Insufficient draft, surface issues

|

Draft angles, surface finish

|

|

Part Sticking to Core

|

Part adheres to core side

|

Poor ejection, cooling problems

|

Ejection system, cooling

|

|

Runner/sprue Sticking

|

Runner remains in mold

|

Design flaws, temperature issues

|

Runner design, temperature

|

|

Nozzle Sticking

|

Material stuck at nozzle

|

Temperature, pressure problems

|

Temperature control, cleaning

|

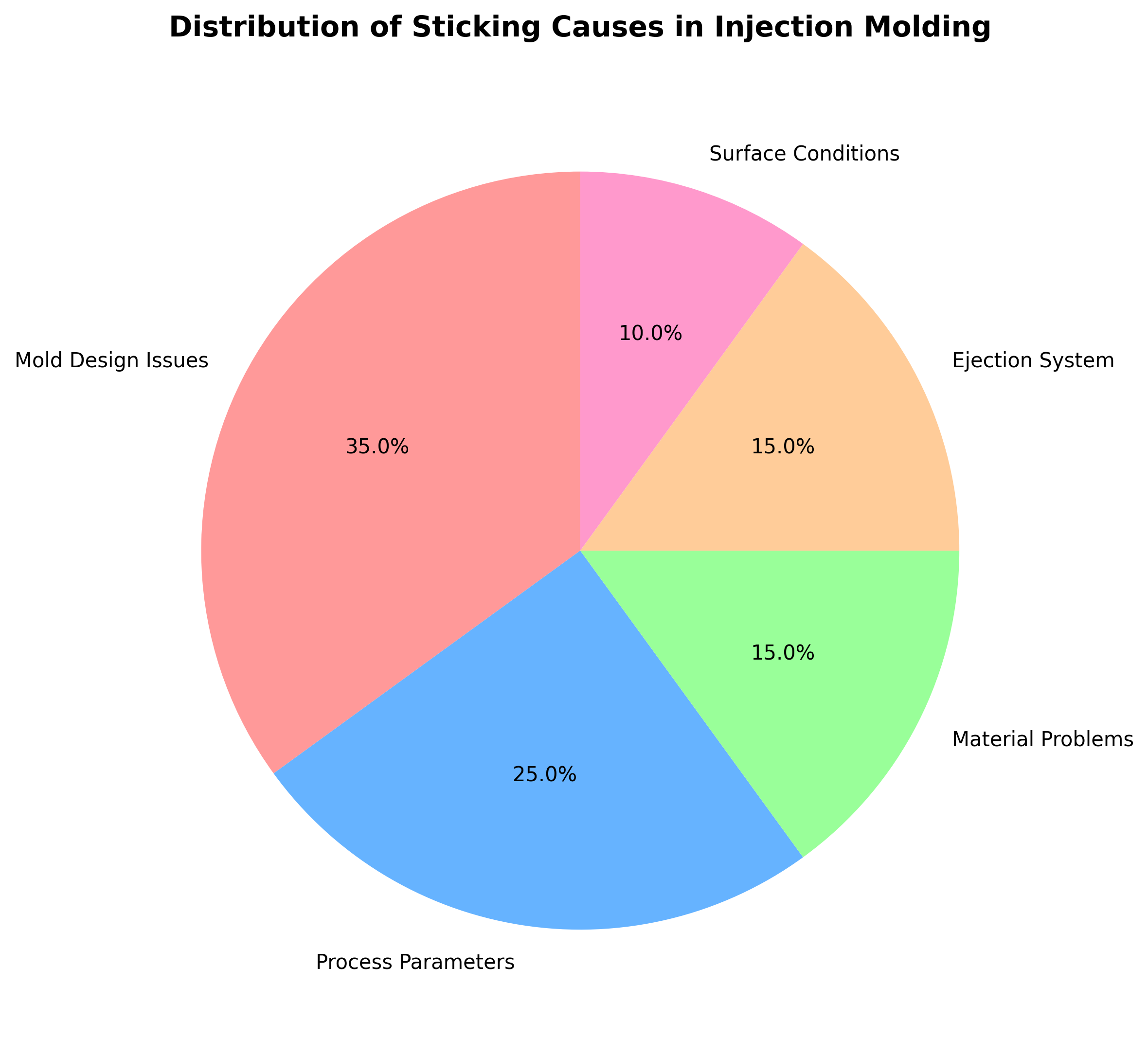

Distribution of Sticking Causes

Sticking Solutions Comparison

Professional Knowledge about Injection Molding Sticking

Mold Design Factors

- Draft Angle Requirements: Minimum 1-3° for simple parts, 5°+ for complex geometries

- Surface Finish: Ra < 0.8μm required, mirror polish (Ra < 0.05μm) recommended for critical surfaces

- Gate Design: Proper gate size and location to ensure balanced filling and easy ejection

- Runner System: Tapered runners with sufficient draft angles (1-3°) for easy removal

- Ejection System: Balanced ejection with adequate stroke and force distribution

Process Parameter Issues

- Temperature Control:

-

- Mold temperature too high increases adhesion

-

- Mold temperature too low causes premature cooling and shrinkage

-

- Nozzle temperature must match material requirements

- Pressure Settings:

-

- Excessive injection pressure increases packing stress

-

- Insufficient holding pressure causes incomplete filling

- Cooling Time:

-

- Too short: Material not fully solidified

-

- Too long: Excessive shrinkage and adhesion

- Injection Speed: Too fast causes turbulence and uneven filling

Material-Related Factors

- Material Viscosity: High viscosity materials require more draft and better surface finish

- Additives and Fillers: Lubricants reduce friction, while fillers can increase adhesion

- Thermal Properties: Materials with high shrinkage rates require careful cooling control

- Moisture Content: Moisture can cause material degradation and increased adhesion

Surface Treatment Solutions

- Polishing: Progressive polishing from 600 grit to 1200 grit or higher

- Coatings: Chrome plating, PVD coatings, or Teflon-based treatments

- Texturing: Controlled surface textures to reduce contact area

- Release Agents: Temporary solutions for difficult materials

Ejection System Optimization

- Ejector Pin Design: Sufficient diameter (≥3mm) and proper spacing

- Ejection Force: Balanced force distribution across the part

- Ejection Speed: 10-30mm/s for optimal performance

- Secondary Ejection: For complex parts requiring multi-stage ejection

Frequently Asked Questions (FAQ)

Q1: What is the minimum draft angle required to prevent sticking?

Q2: How can I improve mold surface finish to prevent sticking?

Q3: What temperature settings help prevent sticking?

Q4: How does material selection affect sticking tendency?

Q5: What ejection system design considerations prevent sticking?

Q6: How can I troubleshoot runner and sprue sticking?

Q7: What role does cooling play in preventing sticking?

Q8: When should I use release agents for sticking issues?

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.

The research results and technical insights shared herein are based on the author’s professional experience and experimental observations. The author and the affiliated institution shall not be liable for any direct, indirect, or consequential damages (including but not limited to equipment damage, product quality issues, or production losses) arising from the improper use of the information provided in this paper.