FAQ Section: Common Questions Answered

What is anodizing and how does it work?

What are the key benefits of anodized aluminum?

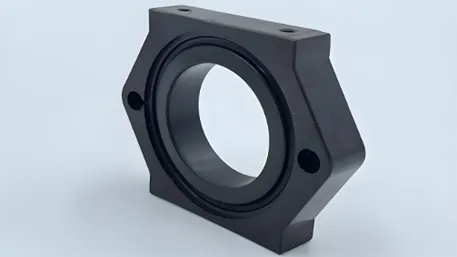

- Enhanced Durability: Anodized finish is the second hardest substance known to man (exceeded only by diamond)

- Corrosion Resistance: Provides excellent protection against environmental factors

- UV Stability: Maintains color and performance even with prolonged sun exposure

- Aesthetic Appeal: Offers a wide range of color options and finishes

- Electrical Insulation: The oxide layer is non-conductive

- Easy Maintenance: Simple to clean and maintain its original appearance

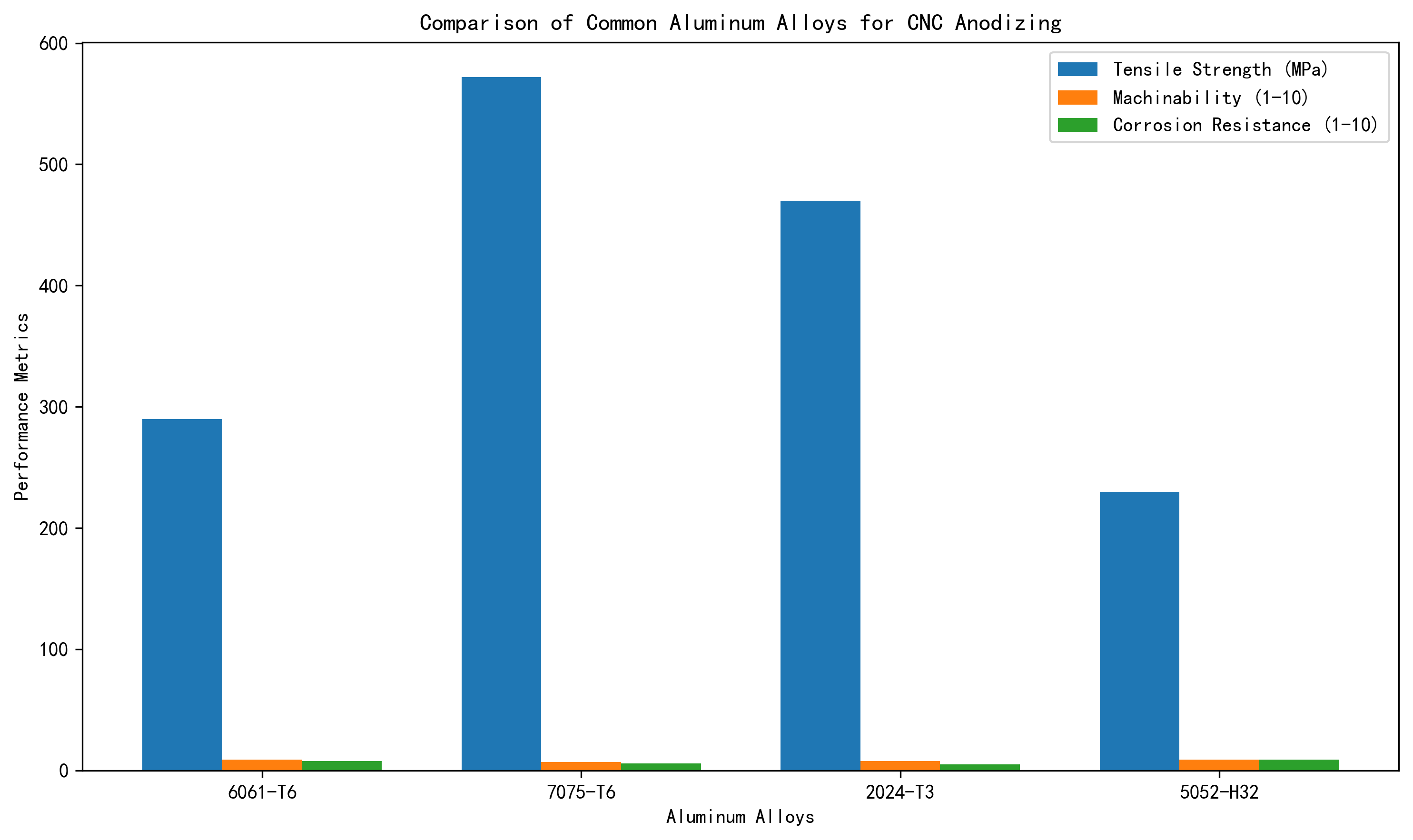

Which aluminum alloys are best for anodizing?

- 6061-T6: Excellent all-around performer with good strength and corrosion resistance

- 7075-T6: High-strength alloy ideal for aerospace applications

- 2024-T3: Strong and fatigue-resistant, commonly used in aircraft structures

- 5052-H32: Superior corrosion resistance, perfect for marine environments

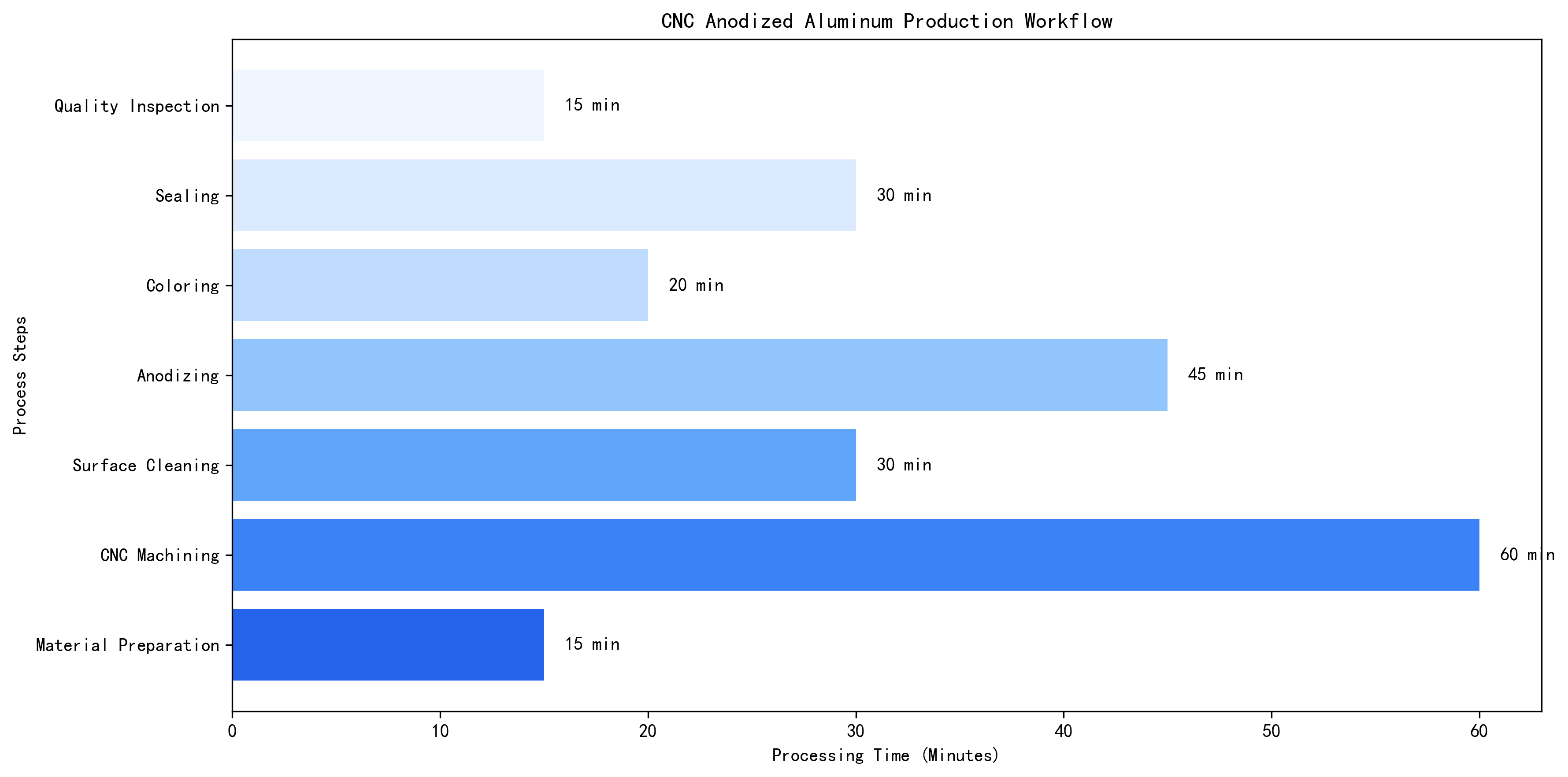

How long does the anodizing process take?

- Surface preparation: 30-60 minutes

- Anodizing process: 30-60 minutes

- Coloring (if required): 15-30 minutes

- Sealing: 20-30 minutes

- Quality inspection: 15-20 minutes

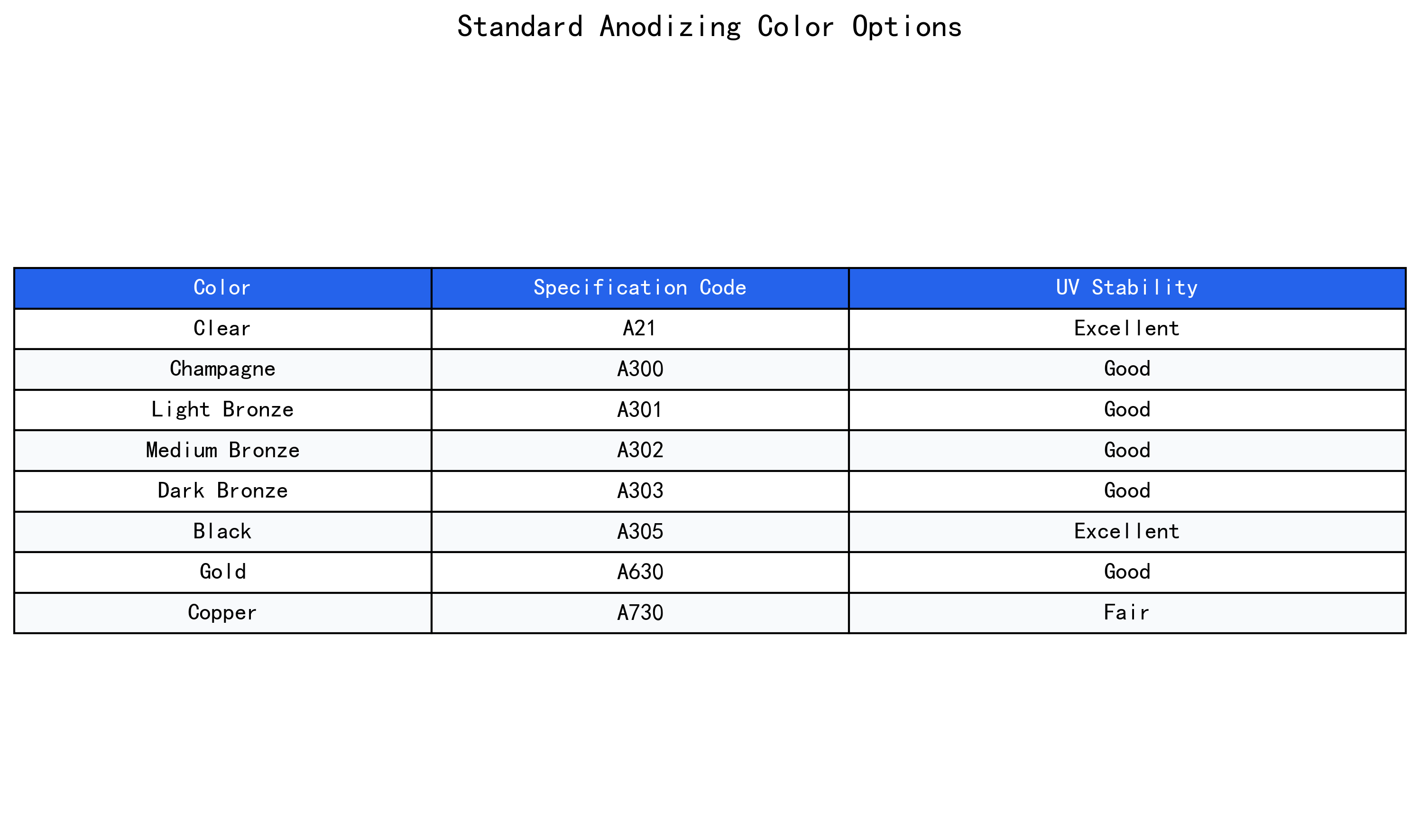

What color options are available?

Practical Guide: Step-by-Step Process

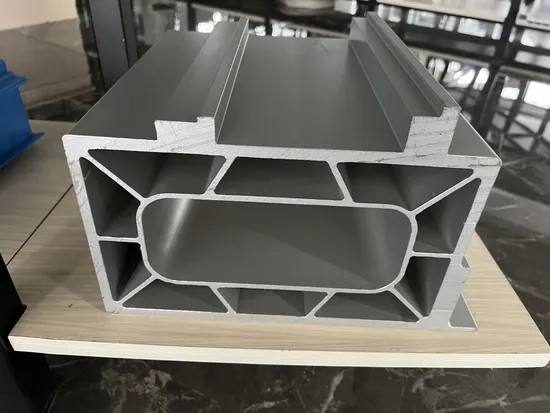

Step 1: Material Selection

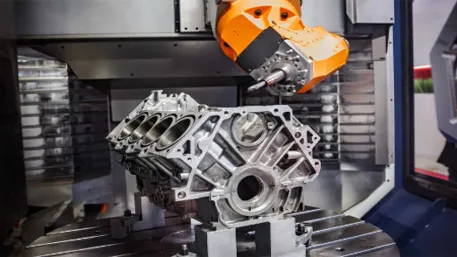

Step 2: CNC Machining

- Program the CNC machine with precise dimensions

- Use proper cutting tools and speeds for aluminum

- Maintain tight tolerances (typically ±0.02mm)

- Ensure smooth surface finish (Ra 0.8-1.6μm)

Step 3: Surface Preparation

- Degreasing: Remove oils and contaminants using alkaline solutions

- Etching: Create uniform surface texture

- Desmutting: Remove smut and impurities

- Rinsing: Thoroughly clean parts between processes

Step 4: Anodizing Process

- Electrolyte Solution: Sulfuric acid (15-20%) at 18-22°C

- Current Application: 1-2 A/dm² at 12-20V

- Processing Time: 30-60 minutes for standard coating

- Film Thickness: 10-20μm for decorative, up to 100μm for hard anodizing

Step 5: Coloring (Optional)

- Organic Dyes: Wide color range, cost-effective

- Inorganic Coloring: More durable, limited color options

- Two-Step Process: Color independent of coating thickness

Step 6: Sealing

- Hot Water Sealing: 95-100°C for 30 minutes

- Cold Nickel Sealing: Room temperature, ideal for dyed parts

- Mid-Temperature Sealing: 80°C, environmentally friendly and efficient

Step 7: Quality Control

- Film Thickness Measurement: Using eddy current instruments

- Corrosion Testing: 5% NaCl salt spray test for 48 hours

- Adhesion Testing: Cross-hatch and tape tests

- Color Consistency: ΔE < 1.0 using spectrophotometer

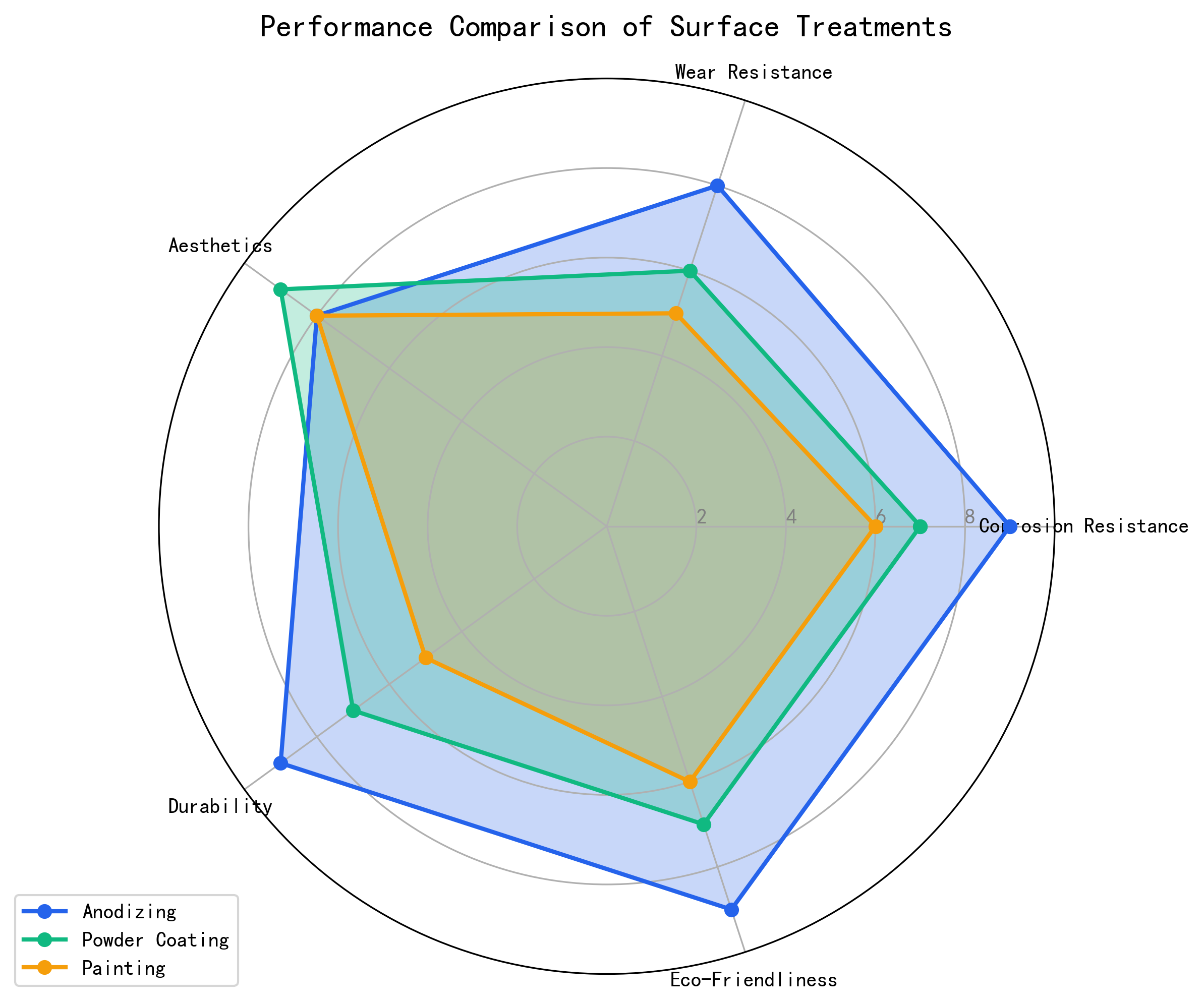

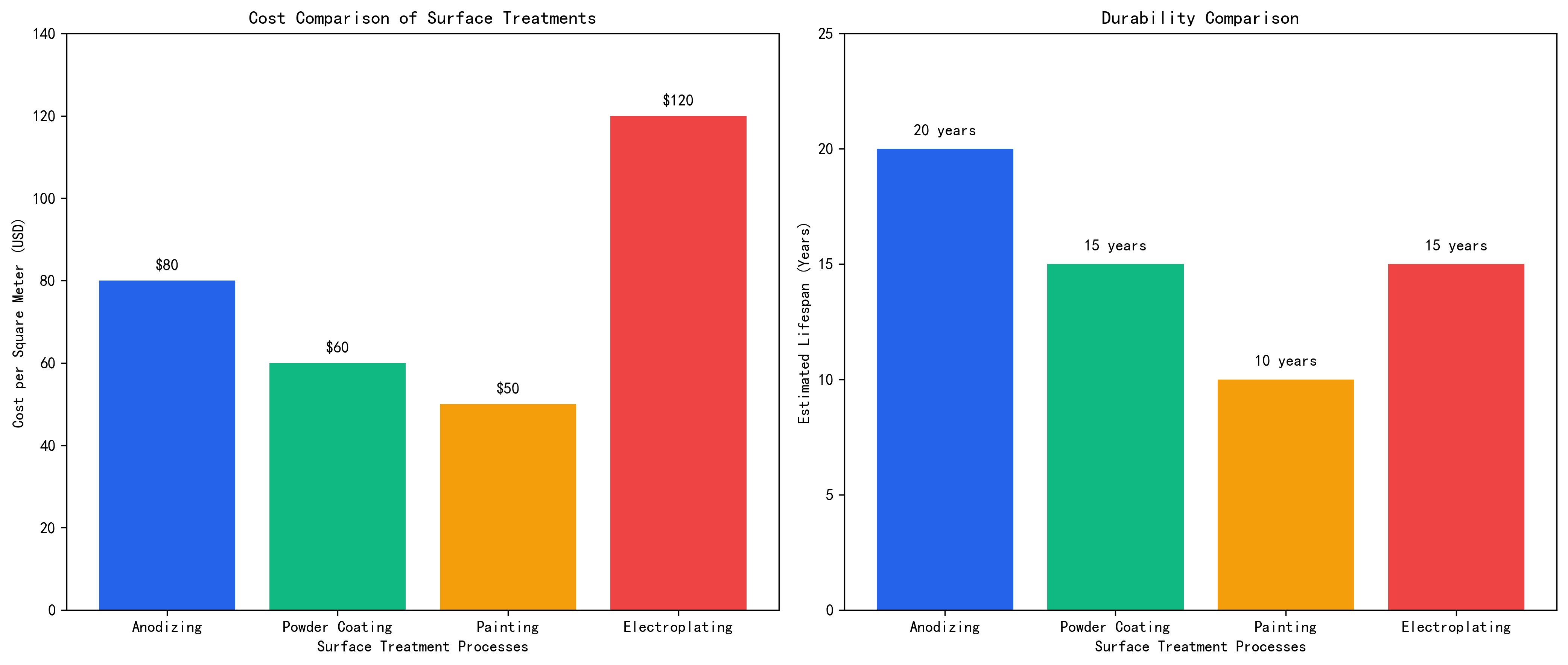

Service Comparison: Anodizing vs. Other Surface Treatments

Cost Comparison

Performance Comparison

Key Differences

|

Feature

|

Anodizing

|

Powder Coating

|

Painting

|

|

Durability

|

Excellent (20+ years)

|

Good (15 years)

|

Fair (10 years)

|

|

Corrosion Resistance

|

Excellent

|

Good

|

Fair

|

|

UV Stability

|

Excellent

|

Good

|

Poor

|

|

Color Options

|

Limited

|

Extensive

|

Unlimited

|

|

Eco-Friendliness

|

Excellent

|

Good

|

Fair

|

|

Cost

|

Moderate

|

Low

|

Low

|

Conclusion

- Choose the right aluminum alloy for your specific application requirements

- Follow proper surface preparation and anodizing parameters

- Consider the total lifecycle cost rather than just initial investment

- Partner with experienced manufacturers for consistent quality results