In the tightly regulated pharmaceutical sector, packaging is pivotal for product safety, efficacy, and regulatory compliance. Custom medical plastic bottles are now essential in healthcare, securely storing various pharmaceutical products, from oral medications to delicate liquid formulations. This article delves into the key capabilities, technical demands, and quality benchmarks of superior custom medical plastic bottle manufacturing.

The Critical Role of Medical Plastic Bottles

Medical plastic bottles serve as the first line of defense for pharmaceutical products, protecting them from:

- Contamination risks from microorganisms and environmental pollutants

- Chemical degradation caused by oxygen, moisture, and light exposure

- Physical damage during transportation and storage

- Tampering and counterfeiting attempts

Key Performance Requirements

Pharmaceutical packaging must meet stringent performance criteria:

- Chemical Compatibility: Inertness to prevent interactions with drug formulations

- Barrier Properties: Resistance to moisture, oxygen, and light transmission

- Mechanical Strength: Impact resistance and structural integrity

- Regulatory Compliance: Adherence to global pharmacopeial standards

- Patient Safety: Child-resistant features and ease of use

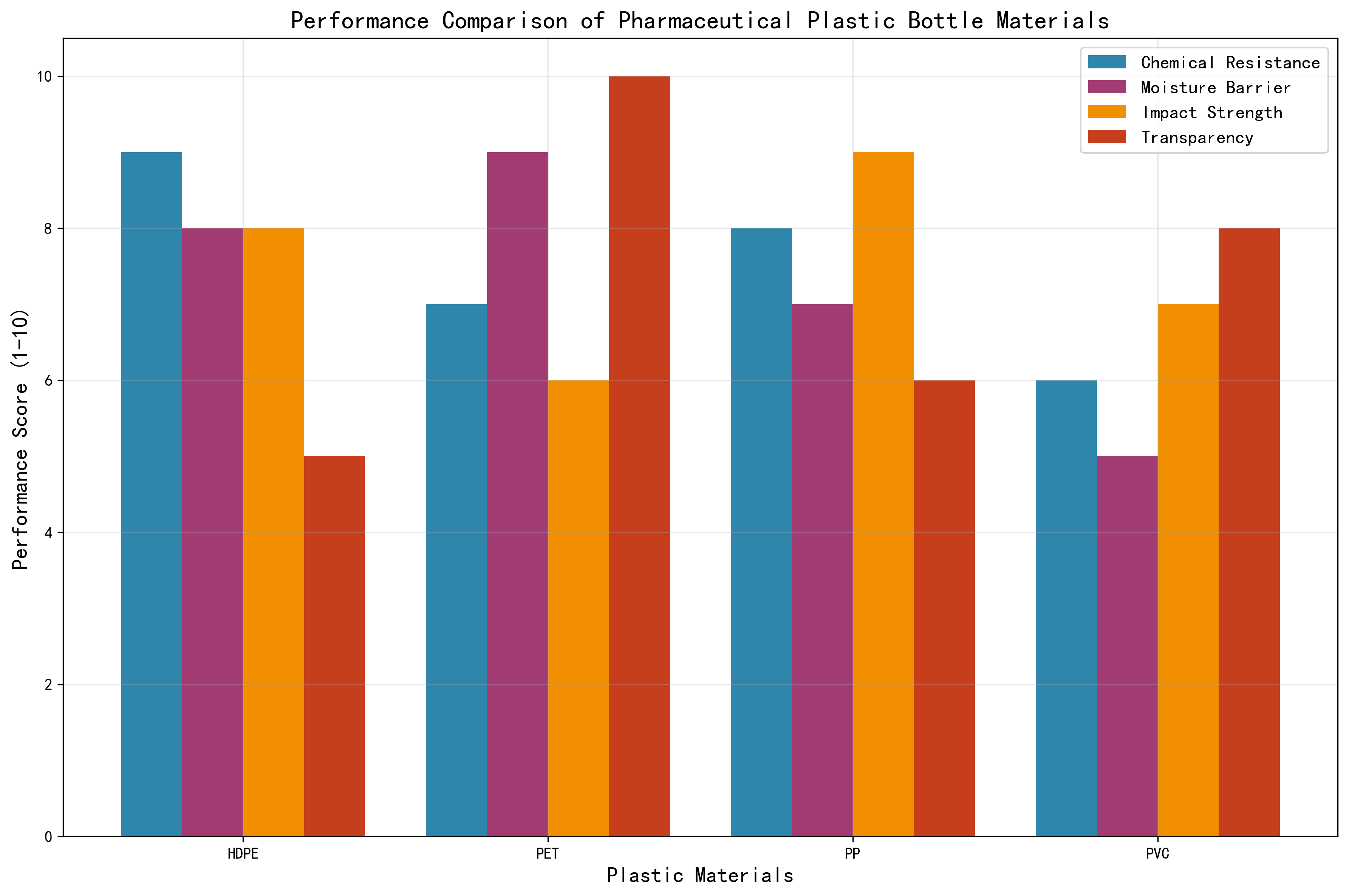

Material Science: Choosing the Right Polymer

The selection of plastic materials is a critical decision in medical bottle design. Each polymer offers unique properties that must be matched to the specific pharmaceutical application.

Primary Materials for Medical Applications

High-Density Polyethylene (HDPE)

- Advantages: Excellent chemical resistance, moisture barrier, impact strength

- Applications: Solid dose medications, tablets, capsules

- Compliance: USP Class VI, FDA approved

Polyethylene Terephthalate (PET)

- Advantages: High transparency, good oxygen barrier, recyclable

- Applications: Liquid medications, vitamins, cosmetics

- Compliance: EU 10/2011, FDA 21 CFR

Polypropylene (PP)

- Advantages: High heat resistance, chemical inertness, autoclavable

- Applications: Medical devices, laboratory reagents, sterile products

- Compliance: ISO 10993, USP <87> Biological Reactivity

Polyvinyl Chloride (PVC)

- Advantages: Flexibility, clarity, cost-effective

- Applications: IV bags, blood collection, certain liquid formulations

- Considerations: Phthalate-free formulations for pharmaceutical use

Customization Capabilities and Technical Specifications

Design Flexibility

Modern manufacturing techniques enable unprecedented design customization:

- Shape and Size: From micro-dosing vials to large-format containers

- Color Options: Amber for light-sensitive drugs, custom branding colors

- Surface Features: Textured grips, measurement scales, ergonomic designs

- Closure Systems: Child-resistant caps, tamper-evident seals, dropper assemblies

Advanced Manufacturing Processes

Injection Blow Molding (IBM)

- Precision: ±0.005mm dimensional accuracy

- Applications: Small volume bottles, high-precision containers

- Advantages: Excellent neck finish quality, consistent wall thickness

Extrusion Blow Molding (EBM)

- Flexibility: Wide range of sizes and shapes

- Efficiency: High production volumes, cost-effective

- Applications: Larger containers, specialty shapes

Stretch Blow Molding (SBM)

- Strength: Enhanced mechanical properties through molecular orientation

- Clarity: Superior transparency for PET bottles

- Lightweighting: Reduced material usage without compromising performance

Quality Control and Regulatory Compliance

Comprehensive Testing Protocols

Stringent quality control is implemented at every stage:

- Incoming Material Inspection

-

- Resin certification and traceability

-

- Particle contamination testing

-

- Melt flow index verification

- In-Process Quality Assurance

-

- Dimensional measurement (CMM, optical comparators)

-

- Wall thickness uniformity

-

- Visual inspection systems

- Final Product Testing

-

- Leak testing under pressure

-

- Seal integrity verification

-

- Compatibility testing with drug formulations

-

- Accelerated aging studies

Global Regulatory Standards

- United States: FDA 21 CFR, USP/NF standards

- European Union: EU GMP, Ph. Eur., REACH compliance

- International: ISO 15378, WHO GMP guidelines

- Specialized: cGMP for sterile products, ISO 8317 for child resistance

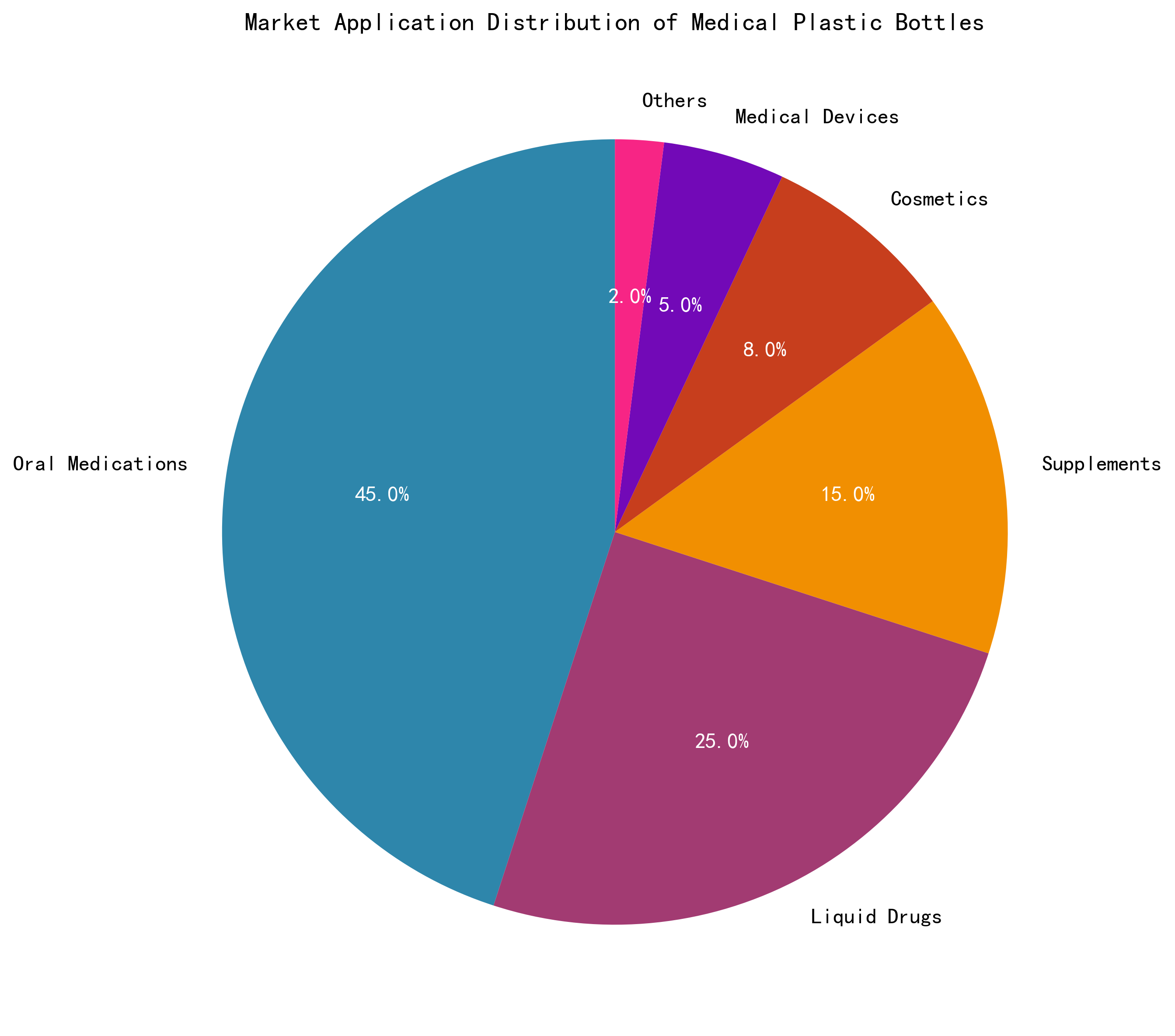

Market Applications and Industry Trends

Key Market Segments

- Pharmaceutical Industry (45% market share)

- Biotechnology Sector (25% market share)

-

- Biologics and biosimilars

- Nutraceuticals and Supplements (15% market share)

-

- Sports nutrition products

- Cosmeceuticals (8% market share)

Emerging Trends

- Sustainable Packaging: Bio-based polymers and recyclable materials

- Smart Packaging: NFC tags, temperature indicators, serialization

- Personalized Medicine: Small-batch production capabilities

- Anti-Counterfeiting: Holographic features, track-and-trace systems

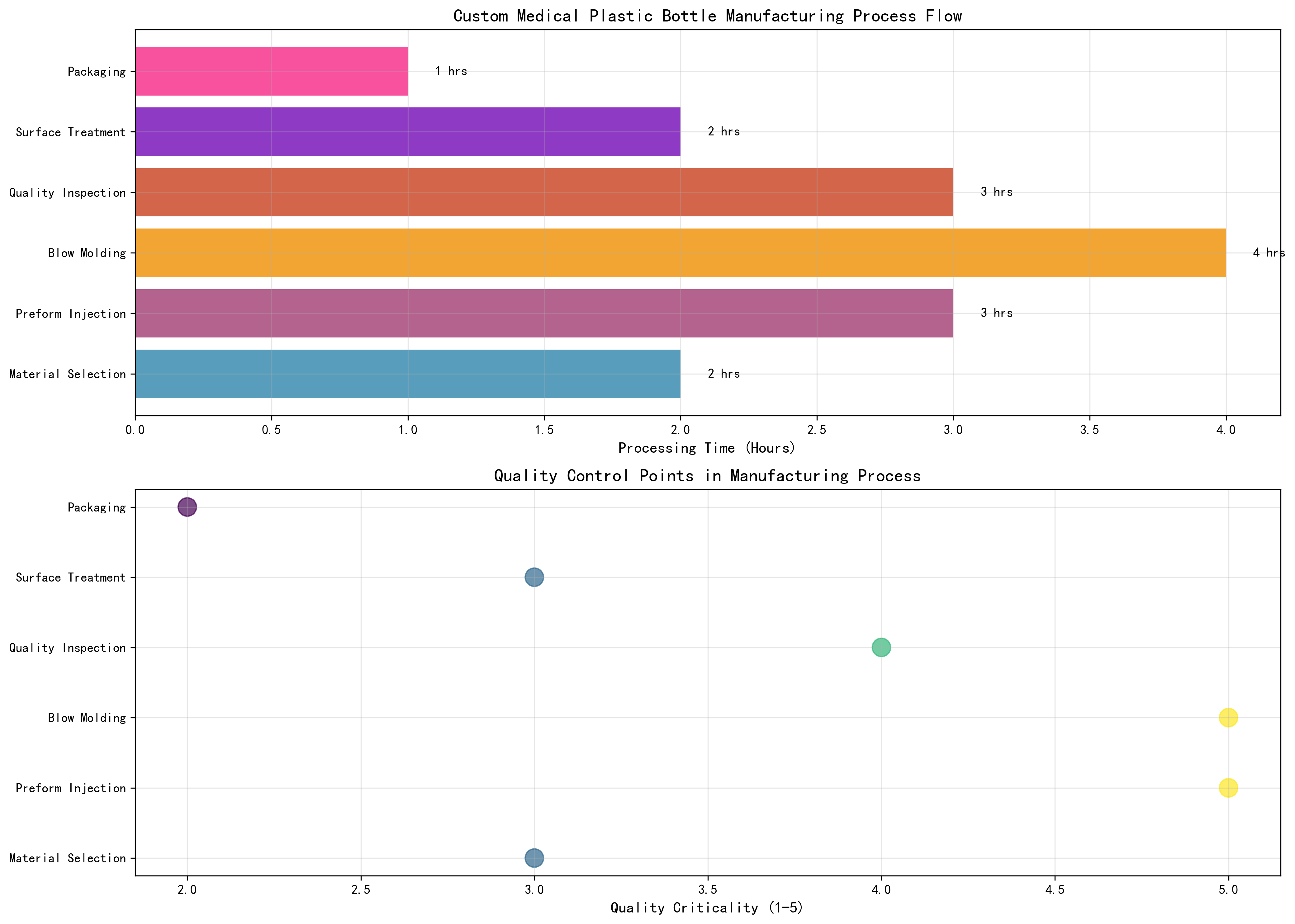

Manufacturing Process Flow

The custom medical plastic bottle manufacturing process involves several critical stages:

- Material Selection and Preparation (2 hours)

-

- Resin drying and conditioning

-

- Colorant and additive mixing

- Preform Injection Molding (3 hours)

-

- Temperature and pressure control

-

- Preform quality inspection

- Blow Molding (4 hours)

-

- Stretch ratio optimization

-

- Dimensional accuracy control

- Quality Inspection (3 hours)

-

- Manual sampling protocols

-

- Statistical process control

- Surface Treatment (2 hours)

- Packaging and Distribution (1 hour)

-

- Documentation and traceability

Why Choose Xiamen Goldcattle for Your Custom Medical Packaging Needs

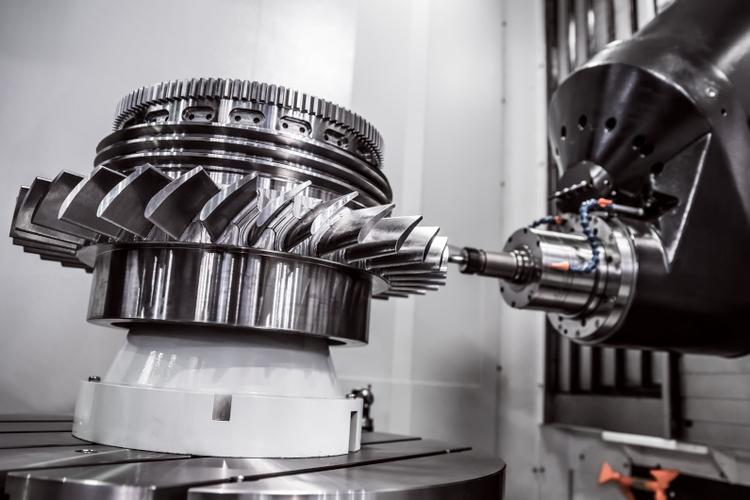

When it comes to custom medical plastic bottle manufacturing, Xiamen Goldcattle stands out as a trusted partner for pharmaceutical companies worldwide. With 26 years of specialized experience in precision manufacturing, we offer:

Technical Excellence

- State-of-the-Art Facilities: 100+ advanced CNC machines including 5-axis processing centers

- Precision Engineering: ±0.005mm manufacturing tolerance for critical applications

- Material Expertise: Deep knowledge of pharmaceutical-grade polymers and their applications

Quality Commitment

- ISO 9001:2000 Certified: Adherence to international quality management standards

- Comprehensive Testing: In-house laboratory with advanced analytical capabilities

- Regulatory Compliance: Full support for FDA, EU, and global regulatory requirements

Customization Capabilities

- Design Flexibility: From concept to production with rapid prototyping

- Material Selection: HDPE, PET, PP, and specialty polymers for every application

- Surface Finishes: Custom colors, labeling, and functional coatings

Service Advantages

- One-Stop Solution: From mold design to finished product delivery

- Quick Turnaround: 1-30 day production lead times

- Technical Support: Dedicated engineering team for product development

Global Reach

- International Certifications: SGS, RoHS, CE, and PR compliant

- Global Customer Base: Serving clients in North America, Europe, Asia, and beyond

- Export Experience: Expertise in international logistics and documentation

Take the Next Step in Your Medical Packaging Journey

At Xiamen Goldcattle, we understand the critical role that packaging plays in pharmaceutical product success. Our commitment to quality, innovation, and customer satisfaction makes us the ideal partner for your custom medical plastic bottle needs.

Contact us today to discuss your specific requirements and discover how our precision manufacturing capabilities can elevate your pharmaceutical packaging to new levels of excellence.

How to Get Started

- Request a Consultation: Share your product specifications and requirements

- Receive Custom Proposal: Get a detailed quotation with technical recommendations

- Prototype Development: Fast-track your project with our rapid prototyping services

- Production Launch: Seamless transition from development to full-scale manufacturing

With Xiamen Goldcattle, you’re not just getting a supplier – you’re gaining a strategic partner dedicated to your pharmaceutical packaging success.

Xiamen Goldcattle Industrial & Trade Co., Ltd.

Precision Manufacturing for a Healthier World

26 Years of Excellence in Custom Medical Packaging

This article provides general information about custom medical plastic bottle services. For specific technical requirements and regulatory guidance, please consult with qualified professionals in the pharmaceutical packaging industry.