Market Trends: More Need for Better Brakes

- Global Market Size: The world market for car brake discs was (15.95 billion in 2024. It will grow to )23.62 billion by 2032, increasing by 5.4% each year.

- Regional Market: North America has the biggest market share at 44.13%. Asia Pacific is growing the fastest.

- Material Changes: Cast iron is still the most common material. But carbon-ceramic materials are becoming popular for high-performance cars.

- Safety Rules: Strict safety standards like ECE R90 and FMVSS 135 push us to make more precise brake discs.

Our Four Key Skills

1. Choosing the Right Materials

- Gray Cast Iron HT250/HT300: Carbon content 3.1-3.4%, Silicon 1.8-2.3%, Manganese 0.6-0.9%

- Ductile Iron: For big trucks, it can handle pulling force over 450MPa

- Aluminum Alloys: 6061-T6 for brake calipers, reduces weight by up to 40%

- Carbon-Ceramic Composites: For racing cars, can handle temperatures over 1000℃

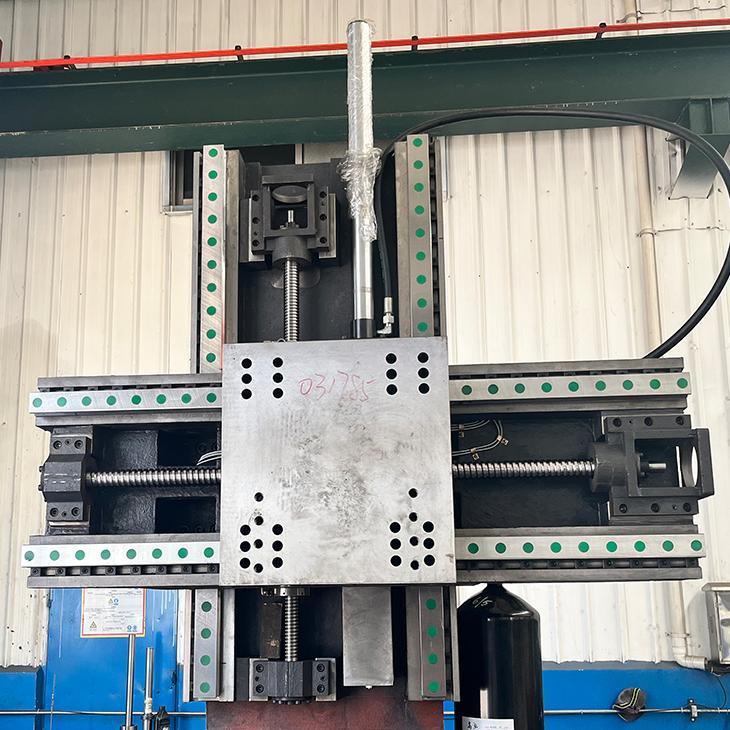

2. Precision CNC Machining

- CNC Vertical Lathes: Can position with ±0.005mm accuracy, repeat the same cut within ±0.002mm

- 5-Axis Machines: For complex designs and cooling patterns

- Grinding Technology: Makes surfaces very smooth (Ra ≤1.2μm), keeps surfaces flat (≤0.02mm/m)

- Laser Drilling: Makes cooling holes with ±0.03mm accuracy

3. Heat Treatment and Surface Work

- Normalizing Process: Heat to 850-900℃, cool slowly to 600℃, then air cool

- Tempering: Heat to 550-600℃ for 3-4 hours, makes hardness 180-220HB

- Stress Relief: Heat to 200℃ for 4 hours, reduces stress to ≤12MPa

- Surface Coatings: Ceramic coatings for racing, thickness 50-80μm

4. Quality Control and Testing

- Size Checks: Thickness difference ≤0.01mm, wobble ≤0.05mm

- Strength Tests: Hardness 179-241HB, pulling strength ≥250MPa

- Heat Resistance: Test from 20-650℃ 100 times without cracking

- Balance Testing: For passenger cars, residual imbalance ≤15g·cm

How We Make Custom Brake Discs

Understanding Your Needs

- Check Your Vehicle: Look at what your car needs

- Recommend Materials: Suggest the best materials for your car

- Analyze Heat: Test how heat will spread

- Optimize Design: Improve cooling patterns and thickness

Design and Development

- 3D Modeling: Use CATIA/Creo to design with adjustable cooling patterns

- Computer Simulation: Test heat stress, long-term use, and vibration

- Program Tool Paths: Plan the best way to cut for minimal tool wear

- Make Prototypes: Test designs quickly

Production and Quality Check

- CNC Machining: Cut → Grind → Drill → Smooth edges

- Heat Treatment: Use controlled ovens with precise temperature control

- Surface Finishing: Add anti-rust coatings, UV protection

- 100% Inspection: Check with coordinate measuring machines, roundness testers, hardness testers

Our Quality System

International Certifications

- IATF 16949:2016: Quality system for the auto industry

- ISO 9001:2015: General quality management

- ECE R90: European brake part certification

- FMVSS 135: US Federal safety standard

Testing Capabilities

- Brake Testing: 100 stops to check fade and recovery

- Salt Spray Testing: 96-hour salt spray test

- Metal Structure Analysis: Check metal grain structure

- Vibration Testing: Prevent noise and vibration issues

Why Choose Our Custom Solutions

Performance Comparison

|

Performance

|

Industry Standard

|

Our Capability

|

Improvement

|

|

Thickness Accuracy

|

±0.03mm

|

±0.01mm

|

67% better

|

|

Surface Smoothness

|

Ra 1.6μm

|

Ra 1.2μm

|

25% smoother

|

|

Flatness

|

0.05mm/m

|

0.02mm/m

|

60% better

|

|

Balance Accuracy

|

≤20g·cm

|

≤12g·cm

|

40% better

|

|

Production Time

|

15-20 days

|

7-10 days

|

50% faster

|

Material Knowledge

- Cast Iron Expertise: 26 years working with HT250/HT300

- Lightweight Solutions: Aluminum designs for electric cars

- Special Alloys: Custom mixes for high-performance needs

- Eco-Friendly Materials: Low-copper content for the environment

Case Study: Luxury Electric Car Brake Discs

- Work with electric braking

- Handle 2.5-ton vehicle weight

- Work at 200km/h top speed

- Fit 800V electrical system

- Material Innovation: HT300 friction surfaces with aluminum center

- CNC Machining: 5-axis cutting for complex cooling pattern

- Surface Treatment: Ceramic coating handles up to 800℃

- Quality Check: 100% precision testing

Future Technology Plans

Better Materials

- Graphene-Enhanced Composites: Better heat transfer and wear resistance

- 3D Printed Discs: Optimized internal structures

- Smart Materials: Temperature-sensitive alloys that adapt

- Recycled Materials: Reused materials with same performance

Advanced Manufacturing

- AI-Enhanced CNC: Computer learning for tool wear prediction

- Digital Twin Technology: Virtual testing before making

- Automated Inspection: AI-powered visual checks

- Green Manufacturing: Energy-saving processes with less waste

Conclusion: Your Trusted Brake Partner

- Visit our website: https://www.xmgoldcattle.com/