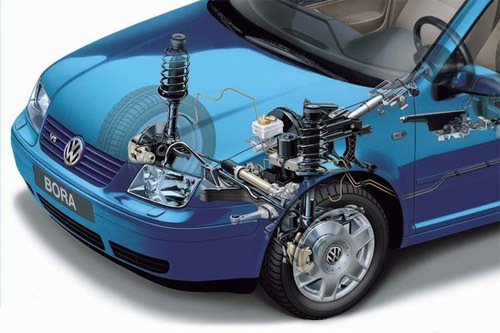

Why Your Car's "Hidden Heroes" Matter

Hello, I’m the Technical Director of Xiamen Gold Cattle. Today, I want to show you how we make custom shock absorber parts.

The Growing Market for Better Rides

Let’s start with some important facts:

- Global Market Size: The world market for car shock absorbers was (15.88 billion in 2024. It will grow to )22.59 billion by 2034, increasing by 4.5% each year.

- Technology Changes: Electronic shock absorbers (CDC) are becoming more popular. They went from 5% use in 2019 to 18% in 2024. Experts think this will reach 35% by 2028.

- EV Impact: Electric cars are now 40% of new car sales. They need special shock absorbers because of their weight and noise needs.

- Aftermarket Demand: In the US alone, over 68 million shock absorbers are sold each year. 45% of these are replacement parts.

These numbers show that shock absorber technology is changing fast. People want more comfort, safety, and better performance.

What Makes a Great Shock Absorber?

A good shock absorber has several key parts. Each needs precise CNC machining:

1. Piston Rods: The Main Part

The piston rod is the most important part of any shock absorber. Our CNC machines make them with:

- Strong Materials: We use high-strength steel (4140, 4340) that can handle over 1000MPa of pulling force.

- Exact Sizes: The diameter is accurate to ±0.005mm. This ensures consistent performance.

- Smooth Surfaces: We polish the surface to Ra ≤0.2μm. This reduces wear and oil leaks.

- Straightness: The rod is straight within 0.05mm per meter. This prevents seal damage.

2. Working Pistons: Controlling the Flow

These parts control how oil moves through the shock absorber:

- Precision Drilling: The holes for oil flow are placed within ±0.01mm of their target.

- Accurate Grooves: The channels that control damping are cut to ±0.02mm width.

- Flat Surfaces: The piston surface is flat within 0.005mm. This ensures proper sealing.

- Strong Materials: We use hardened aluminum alloy (6061-T6) with surface treatment.

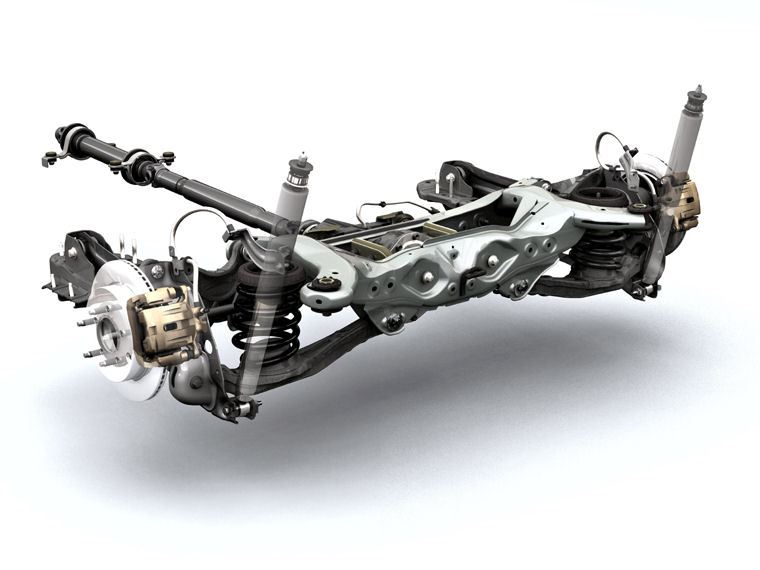

3. Cylinders and Housings: Holding It All Together

The outer shell must handle high pressure while keeping its shape:

- Smooth Inside: The inner surface is polished to Ra ≤0.4μm.

- Round Shape: The cylinder is round within 0.008mm. This lets the piston move freely.

- Even Walls: The wall thickness is consistent to ±0.03mm. This helps with heat dissipation.

- Strong Materials: We use seamless steel tubes with uniform grain structure.

4. Mounting Brackets: Connecting Parts

These parts connect the shock absorber to the car:

- Complex Shapes: We use 5-axis CNC machines to make complex mounting surfaces.

- Exact Holes: The holes for bolts are placed within ±0.02mm. This ensures proper alignment.

- Good Welds: We prepare the metal for strong, consistent welds.

- Corrosion Protection: We apply a special coating to prevent rust.

How We Make Custom Shock Absorbers

1. Understanding Your Needs

Every custom project starts with learning what you need:

- Car Type: Is it a passenger car, SUV, truck, or race car?

- Performance Goals: Do you want comfort, sporty handling, or off-road capability?

- Environment: What temperatures and road conditions will it face?

- Safety Rules: Do you need to meet ISO, SAE, or car maker standards?

2. Designing the Solution

Our engineers use advanced tools:

- Computer Simulation: We test how the part will handle stress.

- Fluid Flow Analysis: We study how oil will move through the shock absorber.

- Material Selection: We choose materials based on how long they will last and how well they resist corrosion.

- Quick Prototypes: We make test parts quickly using CNC machines.

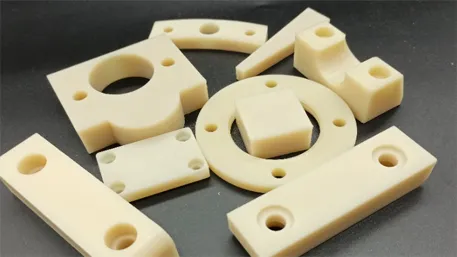

3. Making the Parts

This is where our 26 years of CNC experience shows:

- CNC Turning: We make piston rods and other round parts.

- CNC Milling: We make complex valve bodies and brackets.

- Precision Grinding: We create mirror-like surface finishes.

- Heat Treatment: We harden parts to make them wear-resistant.

4. Testing for Quality

Every part goes through strict testing:

- Size Checks: We measure with machines accurate to ±0.001mm.

- Material Tests: We check hardness, strength, and internal structure.

- Performance Tests: We measure damping force at different speeds.

- Longevity Tests: We simulate road conditions for over 500,000 cycles.

Why Choose Custom CNC Solutions?

Precision You Can Trust

- Tight Tolerances: We hold critical dimensions to ±0.005mm.

- Consistency: Every part is the same within 0.01mm.

- Complex Shapes: We make intricate valve designs using 5-axis machines.

- Smooth Surfaces: Mirror finishes reduce friction and wear.

Material Expertise

- Strong Steels: For high-strength piston rods and structural parts.

- Lightweight Aluminum: For performance applications.

- Rust-Resistant Stainless Steel: For harsh environments.

- Special Materials: Titanium for racing and high-performance use.

Better Performance

- Custom Damping: We adjust valve designs for specific needs.

- Less Weight: We use hollow piston rods and optimized brackets.

- Better Cooling: We add enhanced cooling channels for heavy use.

- No Leaks: Precision dimensions ensure leak-free performance.

Case Study: Winning on the Track

Let me share a recent project:

Customer Challenge:

A race team needed custom shock absorber parts for their championship-winning GT3 race car. The requirements were extreme:

- Operating temperatures up to 120°C

- Piston speeds over 5 meters per second

- Must last 10,000+ race kilometers

- Need 15% less weight than standard parts

Our Solution:

- Lightweight Material: We used titanium alloy (Ti-6Al-4V) for piston rods. This reduced weight by 40% while keeping strength.

- Precision Machining: We used 5-axis machines to make complex valve bodies with 12 individual flow channels.

- Special Coating: We applied diamond-like carbon (DLC) coating to reduce friction and wear.

- Performance Tuning: We adjusted valve stacks based on computer analysis.

The result? The team won their championship with a 2.3-second per lap improvement. This was directly from our custom CNC parts.

Quality Management: Building Trust

Certifications You Can Rely On

- IATF 16949:2016: This is the quality standard for the auto industry.

- ISO 9001:2015: This is the international quality management standard.

- ISO 14001:2015: This shows our commitment to environmental management.

- Customer Standards: We meet the requirements of major car makers.

Process Control

- Real-Time Monitoring: We watch key dimensions as we work.

- First Part Inspection: We check the first part of every new project.

- 100% Checks: We inspect all critical dimensions.

- Final Tests: We do complete size and function checks.

Tracking Every Part

- Material Records: We keep complete batch records for all materials.

- Process Details: We document how every part is made.

- Test Results: We keep all performance test data.

- Warranty Support: We have full documentation for warranty claims.

Future Trends in Shock Absorbers

Smart Shock Absorbers

The future is here with electronic damping systems:

- Sensor Integration: We make precise housings for sensors.

- Electronic Valves: We make high-precision solenoid valve bodies.

- Control Modules: We make enclosures for electronic parts.

- Wireless Connectivity: We add IoT features for predictive maintenance.

Lighter Materials

Electric cars and performance demands are driving this trend:

- Carbon Fiber Parts: We machine hybrid components.

- Magnesium Alloys: These are lightweight with complex shapes.

- 3D Printing: We combine 3D printing with CNC finishing.

- Smart Design: We use less material while keeping strength.

Green Manufacturing

Environmentally friendly technology is becoming more important:

- Dry Machining: We use less coolant with advanced tools.

- Energy Efficiency: We optimize processes to use less energy.

- Recycled Materials: We machine recycled aluminum and steel.

- Less Waste: We nest parts to use over 95% of materials.

Conclusion: Your Journey to Better Rides Starts Here

At Xiamen Gold Cattle, we don’t just make shock absorbers—we build safety and comfort.

Our 26 years of CNC expertise, combined with our passion for car performance, makes us the perfect partner for your custom shock absorber needs.

Whether you’re making luxury cars, race cars, or off-road vehicles, we have the skills to turn your ideas into reality.

Let’s work together to make every ride smoother, safer, and more enjoyable. Because when it comes to shock absorbers, precision isn’t just a requirement—it’s an art form.

Contact Us:

Let’s craft the perfect ride together!