The Global Powerhouse Behind Every Machine

- Global Market Size: The mechanical power transmission market reached (33.18 billion in 2024 and is projected to grow to )62.79 billion by 2032, with a CAGR of 8.3% (Source: Credence Research)

- China’s Dominance: The Chinese mechanical transmission industry reached 8500 billion yuan in 2024, growing at an impressive 12% annual rate, with domestic manufacturers now controlling 75% of the key component supply chain

- Industry Transformation: Demand for high-efficiency reducers, precision control systems, and integrated powertrain modules has grown from 35% in 2020 to 58% in 2025

- Emerging Applications: Industrial robots alone consume over 8 million precision cycloidal and harmonic reducers annually, while the renewable energy sector is driving unprecedented demand for high-power gearboxes

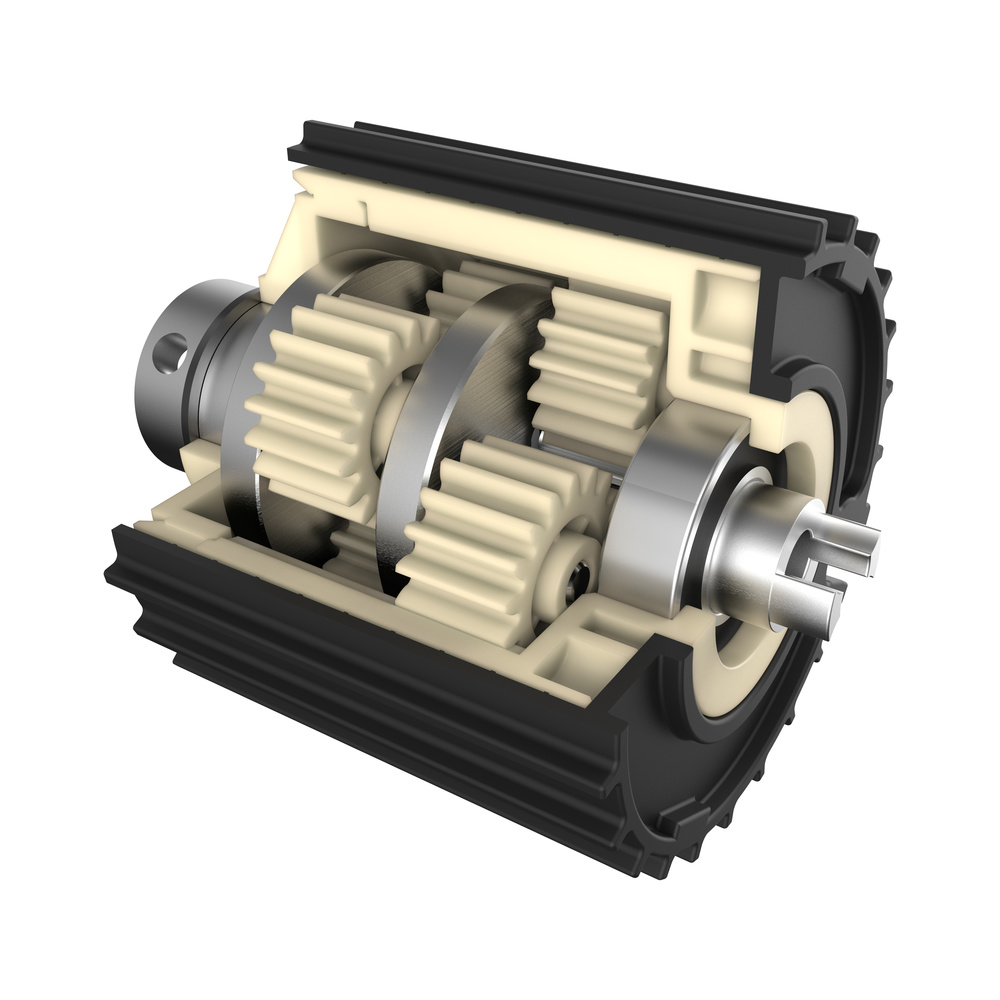

The Evolution of Power Transmission: From Simple to Sophisticated

The Basic Principles

- Gears: The most common type, with teeth that mesh together to transmit power

-

- Spur Gears: Straight teeth, parallel shafts

-

- Helical Gears: Angled teeth for smoother operation

-

- Bevel Gears: For intersecting shafts

-

- Worm Gears: For large speed reductions

- Pulleys and Belts: Using friction to transmit power

-

- Timing Pulleys: Synchronous transmission with toothed belts

-

- V-Belts: Wedge-shaped belts for high torque

-

- Flat Belts: Simple, efficient transmission

- Sprockets and Chains: Positive drive systems

-

- Roller Chains: High strength for heavy loads

-

- Silent Chains: Reduced noise for precision applications

- Couplings and Clutches: Connecting and disconnecting shafts

-

- Flexible Couplings: Accommodating misalignment

-

- Rigid Couplings: Precise alignment for high accuracy

-

- Electromagnetic Clutches: On-demand engagement

The CNC Revolution: Precision Redefined

The Challenges of Traditional Manufacturing

- Manual Setup: Time-consuming and prone to human error

- Limited Complexity: Difficulty producing complex geometries

- Inconsistent Quality: Variations between batches

- Long Lead Times: Months to produce custom components

How CNC Technology Changed Everything

1. Unmatched Precision

- Positioning Accuracy: ±0.005mm for critical dimensions

- Repeatability: ±0.002mm part-to-part consistency

- Surface Finish: Ra ≤0.8μm for optimal performance

- Complex Geometries: 5-axis machining for intricate designs

2. Material Versatility

- High-Strength Alloys: 4140, 8620 steel for automotive applications

- Lightweight Materials: Aluminum 7075 for robotics

- Specialized Alloys: Titanium for aerospace

- Non-Metallic: PEEK, POM for corrosion resistance

3. Manufacturing Methods

- Gear Hobbing: For high-volume spur and helical gears (AGMA Class 10-12)

- Gear Milling: Prototypes and custom profiles (AGMA Class 9-11)

- Gear Shaping: Internal gears and clusters with excellent accuracy

- CNC Turning: Precise blank preparation with <0.005mm runout

Our Customization Process: Turning Ideas into Reality

1. Application Analysis

- Power Requirements: Torque, speed, and duty cycle

- Environmental Conditions: Temperature, humidity, contamination risks

- Space Constraints: Size and weight limitations

- Performance Goals: Efficiency, noise level, durability requirements

2. Engineering Design

- CAD Modeling: Specialized software like KISSsoft, GearTrax

- FEA Analysis: Finite Element Analysis for load distribution

- Tolerance Stack-up: Accounting for thermal expansion and mounting

- Material Selection: Based on application requirements

3. Prototyping and Validation

- Rapid Prototyping: CNC machined samples in days, not weeks

- Performance Testing: Torque, efficiency, and durability testing

- Environmental Testing: Temperature cycling, corrosion resistance

- Customer Approval: Ensuring complete satisfaction before production

4. Production Excellence

- CNC Machining: Precision turning, milling, and grinding

- Heat Treatment: Case hardening, carburizing, stress relief

- Surface Finishing: Anodizing, plating, painting

- Quality Control: 100% inspection with CMM, roundness testing

Technical Advantages: Why Choose Custom Solutions

Performance Comparison

|

Performance Metric

|

Industry Standard

|

Our Capability

|

Improvement

|

|

Positioning Accuracy

|

±0.01mm

|

±0.005mm

|

50% better

|

|

Repeatability

|

±0.005mm

|

±0.002mm

|

60% improvement

|

|

Transmission Efficiency

|

85-90%

|

95%+

|

5-10% better

|

|

Production Lead Time

|

4-6 weeks

|

1-2 weeks

|

50% faster

|

|

Customization Capability

|

Limited

|

Unlimited

|

Complete flexibility

|

Material Expertise

- Optimize Performance: Selecting the right material for each application

- Enhance Durability: Through specialized heat treatment

- Reduce Weight: Using lightweight alloys where appropriate

- Improve Efficiency: Minimizing friction and wear

Application-Specific Solutions

- High-Precision Gears: For robotics and medical equipment

- Heavy-Duty Gearboxes: For industrial machinery and wind turbines

- Compact Transmissions: For space-constrained applications

- Low-Noise Solutions: For consumer and office equipment

Case Study: Revolutionizing Wind Energy

Customer Challenge

- Power Output: 8MW capacity

- Operating Conditions: -40°C to 60°C temperature range

- Service Life: 20+ years with minimal maintenance

- Weight Reduction: 15% compared to existing designs

Our Solution

- Material Innovation: Using high-strength alloy steel with improved fatigue resistance

- Design Optimization: Planetary gear configuration for compact size and high efficiency

- CNC Precision: 5-axis machining for complex internal geometries

- Quality Assurance: 100% inspection and load testing

Results

- Weight Reduction: 18% achieved (exceeding target)

- Efficiency: 98.5% transmission efficiency

- Noise Level: 10dB reduction compared to previous design

- Service Life: Projected 25+ years based on accelerated testing

Future Trends: The Next Generation of Power Transmission

Smart Transmission Systems

- Condition Monitoring: Built-in sensors for vibration, temperature

- Predictive Maintenance: AI-powered failure prediction

- Adaptive Control: Automatic adjustment based on load conditions

- IoT Connectivity: Remote monitoring and diagnostics

Sustainable Manufacturing

- Energy Efficiency: Optimized designs for maximum efficiency

- Recycled Materials: Using reclaimed alloys and composites

- Reduced Waste: Precision machining for minimal material usage

- Longer Life: Reducing replacement frequency

Advanced Materials

- Graphene-Enhanced Lubricants: Reducing friction and wear

- Composite Materials: Carbon fiber for lightweight strength

- Shape Memory Alloys: Self-healing capabilities

- 3D Printed Components: Complex internal geometries

Conclusion: Powering the Future, One Gear at a Time

- Visit our website: https://www.xmgoldcattle.com/