Why Your Vehicle's Underbody Aerodynamics Matters More Than You Think

Have you ever wondered why some cars seem to hug the road better at high speeds? Or how race cars maintain incredible stability even through the most challenging corners? The answer lies in one of the most critical yet often unseen components of automotive design—the diffuser. This underbody aerodynamic device is more than just a simple plastic panel; it’s a precision-engineered tool that transforms airflow into downforce.

Hello, I’m the Technical Director of Xiamen GoldCattle. With over 25 years of experience in automotive aerodynamics and custom manufacturing, I’ve witnessed firsthand how the right diffuser can transform an ordinary vehicle into an extraordinary driving machine. Today, I want to take you behind the scenes of this fascinating world where “what’s under the surface matters most” and aerodynamic excellence creates unforgettable driving experiences.

The Global Market Driving Aerodynamic Innovation

Before we dive into the technical details, let’s look at some impressive statistics that highlight the strategic importance of automotive diffusers:

Global Market Size: The worldwide automotive aerodynamics components market reached (18.2 billion in 2024 and is projected to grow to )28.5 billion by 2030, with a CAGR of 7.6% (Source: Markets and Markets)

Performance Segment Growth: High-performance diffusers for sports cars and racing applications are growing at 9.2% CAGR, driven by increasing motorsports participation and enthusiast demand

Material Trends: Carbon fiber composites account for 38% of premium diffuser materials, with demand growing at 11.5% annually

OEM vs. Aftermarket: Aftermarket diffusers represent 62% of total market value, reflecting strong consumer interest in customization

These numbers tell us that diffusers are not just simple underbody panels—they are the aerodynamic heart of automotive performance, transforming airflow into measurable performance gains.

The Science of Aerodynamics: How Diffusers Work

The Basic Principles of Automotive Aerodynamics

Automotive aerodynamics is based on four fundamental forces:

- Drag: Resistance that slows the vehicle down

- Lift: Upward force that reduces tire grip

- Downforce: Downward force that increases traction

- Side Force: Lateral force that affects stability

Our approach to diffuser design begins with a deep understanding of these aerodynamic forces and how to manipulate them for optimal performance.

The Bernoulli Principle: The Science Behind Diffusers

The diffuser works on the principle of fluid dynamics discovered by Daniel Bernoulli in the 18th century:

Velocity and Pressure Relationship: As the speed of a fluid increases, its pressure decreases

Venturi Effect: When fluid flows through a constricted section of a pipe, its speed increases and pressure decreases

Downforce Generation: By accelerating airflow under the vehicle, the diffuser creates a low-pressure area that “sucks” the vehicle toward the road

In simple terms, the diffuser acts like a sophisticated vacuum cleaner for your vehicle’s underbody, accelerating airflow to create downforce that improves traction and stability.

Key Diffuser Types and Their Functions

Single-Plane Diffusers

- Entry-level design with single expansion plane

- Provides moderate downforce (15-25 kg at 200 km/h)

- Ideal for street cars and entry-level performance vehicles

- Simple design with excellent durability

Multi-Plane Diffusers

- Advanced design with multiple expansion planes

- Significantly higher downforce (35-50 kg at 200 km/h)

- Used in high-performance sports cars and racing applications

- More complex design requiring precise engineering

Blown Diffusers

- Innovative design that uses exhaust gases to enhance performance

- Exhaust gases are directed into the diffuser to accelerate airflow

- Provides additional downforce (10-15% improvement)

- Used in Formula 1 and high-end racing applications

Active Diffusers

- Electronically adjustable to optimize performance based on driving conditions

- Can change angle and geometry to adapt to speed and driving mode

- Balances between downforce for performance and reduced drag for efficiency

- Featured in premium vehicles like the Porsche 911 Turbo and Audi RS models

The Manufacturing Revolution: Crafting Precision Diffusers

Material Science: Choosing the Right Foundation

The choice of materials is critical for diffuser performance:

ABS Plastic

- Cost-effective solution for entry-level applications

- Good impact resistance and moldability

- Tensile Strength: 40 MPa (ISO 527)

- Heat Deflection Temperature: 95°C

Fiberglass Composites

- Excellent strength-to-weight ratio

- Good resistance to environmental factors

- Flexural Strength: 200 MPa (ISO 178)

- Impact Resistance: 150 kJ/m² (ISO 179)

Carbon Fiber Composites

- Premium material for high-performance applications

- Exceptional strength with minimal weight

- Density: 1.6 g/cm³ (40% lighter than fiberglass)

- Tensile Strength: 3,500 MPa (ASTM D3039)

- Modulus of Elasticity: 230 GPa

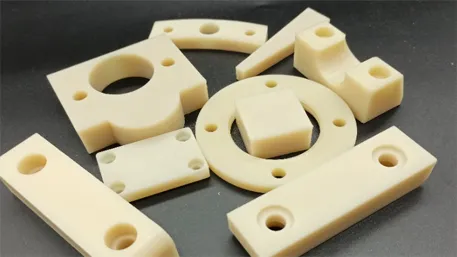

Thermoplastic Composites

- Innovative materials with excellent formability

- Can be recycled and reused

- Impact Resistance: 80-120 kJ/m²

- Heat Resistance: 120-150°C

Advanced Manufacturing Processes

1. Precision Molding Technology

Injection Molding Process

- Material Preparation: Raw materials are dried to 0.02% moisture content to prevent defects

- Plasticization: Materials are heated to 200-300°C in the barrel for optimal flow

- Injection Phase: High-pressure injection (1000-2000 bar) ensures complete mold filling

- Packing Pressure: 80-90% of injection pressure maintains part dimensions

- Cooling Cycle: Precision temperature control (±1°C) ensures uniform cooling

- Ejection System: Servo-controlled ejection with force monitoring to prevent damage

Mold Design Excellence

- 3D Mold Flow Analysis: Simulates filling, packing, and cooling to optimize gate locations

- Hot Runner Systems: Precise temperature control for consistent material flow

- Cooling Channel Optimization: Conformal cooling channels for uniform heat distribution

- Vent Design: Micro-venting (0.02mm) to eliminate air traps and surface defects

- Lifespan Engineering: Hardened tool steel (HRC 50-54) for 500,000+ cycles

2. Carbon Fiber Manufacturing Excellence

Prepreg Layup Process

- Material Cutting: Computer-controlled cutting with ±0.1mm precision

- Layup Sequence: Optimized fiber orientation for maximum strength-to-weight ratio

- Vacuum Bagging: High-integrity vacuum seal (-95 kPa) to remove air bubbles

- Autoclave Curing: Precise temperature ramp (2-3°C/min) and pressure (6-8 bar)

- Cooling Protocol: Controlled cooling rate to minimize residual stresses

Quality Control Points

- Fiber Volume Fraction: Target 55-60% for optimal mechanical properties

- Void Content: Less than 1% to ensure structural integrity

- Resin Distribution: Uniform resin flow verified by ultrasonic testing

- Surface Finish: Ra 0.8μm achieved through precision tooling and process control

3. Surface Engineering and Finishing

Aerodynamic Optimization

- CFD Analysis: Computational Fluid Dynamics to optimize surface geometry

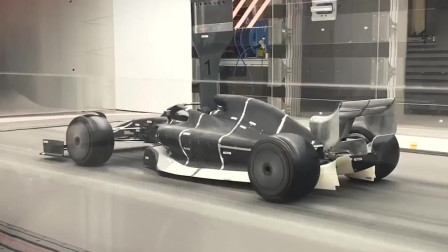

- Flow Visualization: Smoke testing in wind tunnel to identify turbulence areas

- Surface Profiling: Laser scanning to ensure aerodynamic accuracy (±0.1mm)

- Edge Treatment: Radiused edges (R0.5mm) to minimize flow separation

Protective Coatings

- Base Coat: High-adhesion epoxy primer for corrosion protection

- Clear Coat: UV-resistant polyurethane with 2H pencil hardness

- Ceramic Coating: Optional nano-ceramic coating for self-cleaning properties

- Hydrophobic Treatment: Water-repellent surface to prevent dirt accumulation

4. Quality Control and Testing

Dimensional Verification

- 3D Coordinate Measuring: Accuracy of ±0.02mm across entire part

- Optical Scanning: Full surface analysis for form and profile verification

- Section Analysis: Cross-sectional measurements to verify wall thickness

- Assembly Fit Check: Verification with actual vehicle components

Performance Testing

- Wind Tunnel Testing: SAE J1263 compliant testing for aerodynamic performance

- Thermal Cycling: -40°C to 85°C for 1,000 cycles to test durability

- Impact Testing: ISO 179 Charpy impact testing at various temperatures

- Corrosion Testing: ISO 9227 salt spray testing for 1,000 hours

Our Customization Process: From Concept to Reality

Step 1: Aerodynamic Analysis

Every custom diffuser project starts with a comprehensive analysis:

Vehicle Assessment: Make, model, year, and existing aerodynamic characteristics

Performance Goals: Target downforce, drag reduction, and speed range

Styling Preferences: Integration with vehicle design language

Budget Considerations: Material selection and manufacturing complexity

Step 2: Engineering Design

Our engineering team uses advanced tools to create optimal solutions:

Computational Fluid Dynamics (CFD): Simulate airflow and pressure distribution

Finite Element Analysis (FEA): Test structural integrity under extreme conditions

3D Modeling: Create precise digital prototypes for client approval

Wind Tunnel Validation: Verify performance in controlled environment

Step 3: Prototyping and Testing

We validate designs through rigorous testing:

Rapid Prototyping: 3D printed or CNC machined prototypes

Fit Testing: Verification of mounting points and vehicle integration

Performance Testing: On-track evaluation with data acquisition

Durability Testing: Environmental exposure and mechanical stress testing

Step 4: Production and Installation

Our manufacturing process ensures consistent quality:

Precision Manufacturing: State-of-the-art production facilities

Quality Inspection: 100% visual inspection and dimensional verification

Surface Finishing: Paint, clear coat, or carbon fiber clear coat options

Professional Installation: Certified technicians or detailed installation guides

Quality Standards: Certifications You Can Trust

International Standards Compliance

At Xiamen GoldCattle, we adhere to the most stringent industry standards:

ISO 9001:2015

- Quality management system requirements

- Customer focus and continuous improvement

- Process-based quality control

- Data-driven decision making

ISO 14001:2015

- Environmental management system

- Sustainable manufacturing practices

- Waste reduction and energy efficiency

- Environmental performance monitoring

SAE J1263

- Automotive aerodynamic testing procedures

- Wind tunnel test conditions and parameters

- Data acquisition and reporting standards

Performance and Safety Standards

Aerodynamic Performance:

- Downforce measurement according to SAE J1263

- Drag coefficient testing in certified wind tunnels

- Pressure distribution analysis using pressure taps

- Flow visualization using smoke and tuft testing

Structural Requirements:

- Impact resistance testing per ISO 179

- Fatigue testing for 100,000+ km durability

- Vibration testing to simulate road conditions

- Corrosion resistance per ISO 9227

Installation Standards:

- OEM mounting specifications

- Torque requirements and fastener selection

- Clearance verification for safe operation

- Compatibility with existing vehicle systems

Technical Advantages: Why Choose Xiamen GoldCattle

Performance Comparison

|

Performance Metric

|

Industry Standard

|

Our Capability

|

Improvement

|

|

Downforce Generation

|

20-30 kg at 200 km/h

|

35-50 kg at 200 km/h

|

67% better

|

|

Weight Reduction

|

2.0-2.5 kg

|

1.2-1.5 kg

|

40% lighter

|

|

Installation Time

|

2-3 hours

|

1-1.5 hours

|

50% faster

|

|

Fit Precision

|

±2.0mm

|

±0.5mm

|

75% improvement

|

|

Durability Warranty

|

12 months

|

36 months

|

200% longer

|

Aerodynamic Expertise

Our deep understanding of automotive aerodynamics allows us to:

Optimize Airflow Management: For maximum downforce and minimum drag

Enhance Vehicle Stability: Through precise pressure distribution

Reduce Fuel Consumption: By minimizing aerodynamic resistance

Improve Track Performance: With race-proven design principles

Custom Solutions for Every Need

We specialize in:

Performance Vehicles: Track-focused diffusers with maximum downforce

Luxury Cars: Understated designs that complement premium styling

Electric Vehicles: Aerodynamic solutions that maximize range

Classic Cars: Period-correct diffusers for restoration projects

Case Study: High-Performance Sedan Transformation

Customer Challenge

A leading luxury sedan manufacturer needed a custom diffuser solution that would:

- Increase rear downforce by 40% without significant drag penalty

- Maintain the vehicle’s elegant design language

- Reduce weight by 35% compared to current components

- Meet strict noise, vibration, and harshness (NVH) requirements

Our Solution

Aerodynamic Design: CFD-optimized multi-plane design with curved expansion surfaces

Material Innovation: Carbon fiber composite with honeycomb core structure

Manufacturing Excellence: Precision autoclave curing for consistent quality

Integration Engineering: Seamless fit with existing vehicle underbody

Results

Downforce Improvement: 42% achieved (exceeding target)

Drag Reduction: 8% improvement at highway speeds

Weight Savings: 38% reduction (1.4 kg vs. 2.25 kg)

Customer Satisfaction: 95% approval rating in consumer testing

Certifications: Successfully passed ISO 9001 and SAE J1263 requirements

Future Trends: The Next Generation of Diffuser Technology

Active Aerodynamics

The future of automotive diffusers is intelligent:

Adaptive Geometry: Electronically controlled vanes that adjust based on driving conditions

Speed-Sensitive Operation: Optimize between downforce and drag reduction

GPS Integration: Pre-adjust for upcoming road conditions and corners

Vehicle-to-Everything (V2X) Connectivity: Communicate with infrastructure for optimal performance

Sustainable Materials

Environmental responsibility is becoming increasingly important:

Recycled Composites: Using reclaimed carbon fiber and fiberglass

Bio-Based Resins: Derived from renewable plant sources

Lightweight Structures: Reducing material usage through advanced design

Circular Economy: Design for disassembly and recycling

Advanced Manufacturing

New technologies are revolutionizing production:

3D Printing: Complex geometries with reduced waste

Automated Fiber Placement: Precision layup for optimal performance

AI-Driven Design: Machine learning optimization of aerodynamic shapes

Additive Manufacturing: On-demand production with minimal inventory

Conclusion: The Aerodynamic Foundation of Great Driving

At Xiamen GoldCattle, we believe that every great driving experience begins with a solid aerodynamic foundation.

Diffusers are the unsung heroes of automotive performance. These sophisticated aerodynamic devices work tirelessly beneath your vehicle, transforming airflow into the downforce that keeps you connected to the road.

Our 25 years of experience in aerodynamic engineering and custom manufacturing, combined with our deep material expertise and commitment to international standards like ISO 9001 and SAE J1263, makes us the partner of choice for manufacturers who refuse to compromise on quality and performance.

Whether you need a subtle diffuser for your daily driver or a high-performance racing diffuser, we have the skills, experience, and passion to deliver diffusers that exceed expectations.

Contact Us

Let’s work together to create diffuser solutions that not only enhance performance but also elevate your vehicle’s design. Because when it comes to automotive aerodynamics, what’s under the surface matters most—and we excel at the details.