Why Your Driveshaft Matters More Than You Think

The Global Market Driving Composite Innovation

How Carbon Fiber Driveshafts Work

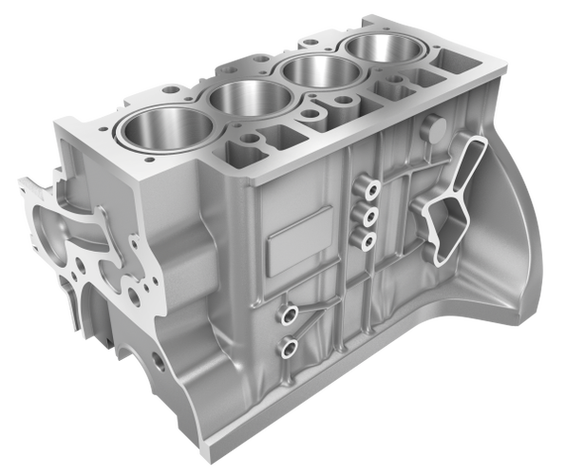

The Basic Functions of a Driveshaft

- Power Transmission: Transfers torque from the engine to the wheels

- Angular Compensation: Accommodates misalignment between transmission and differential

- Vibration Isolation: Absorbs driveline vibrations for smoother operation

- Weight Optimization: Minimizes rotational mass for improved performance

The Physics of Lightweight Performance

- Faster acceleration (0-100km/h improvement of 0.1-0.3 seconds)

- Better throttle response (power delivery delay reduced by 60%)

- Improved braking performance (rotational energy to dissipate is reduced)

- 100% higher torsional stiffness compared to steel (18,000 N·m/° vs. 9,000 N·m/°)

- Reduced power loss through drivetrain wind-up

- More precise power delivery to the wheels

Key Driveshaft Types and Configurations

- Single continuous carbon fiber tube for maximum strength and minimal weight

- Eliminates the need for center support bearings

- Ideal for vehicles with sufficient underbody clearance

- Provides the best performance-to-weight ratio

- Designed for vehicles with limited underbody space

- Uses carbon fiber tubes with aluminum center support

- Maintains performance benefits while accommodating packaging constraints

- Common in luxury sedans and SUVs

- Specialized design for extreme torque applications

- Enhanced torsional stiffness for track use

- SFI 43.1 certified for safety

- Capable of handling over 2,000 horsepower

Material Science: The Carbon Fiber Advantage

Material Selection Criteria

- Strength Requirements: Tensile strength, compressive strength, and fatigue resistance

- Stiffness Needs: Torsional stiffness and bending stiffness for precise power delivery

- Weight Targets: Density optimization for minimal rotational mass

- Environmental Resistance: Corrosion resistance, temperature stability, and UV protection

- Cost Considerations: Balancing performance with affordability

Our Carbon Fiber Expertise

- Premium material for maximum stiffness-to-weight ratio

- Tensile Strength: 3,500 MPa (ASTM D3039)

- Tensile Modulus: 230 GPa

- Density: 1.6 g/cm³ (40% lighter than fiberglass)

- Fatigue Life: 10 million+ cycles at 70% of ultimate strength

- Balanced performance for general applications

- Tensile Strength: 3,000 MPa (ASTM D3039)

- Tensile Modulus: 200 GPa

- Density: 1.6 g/cm³

- Cost-effective solution with excellent performance

- Carbon fiber combined with other materials for specific properties

- Carbon-Kevlar hybrid for impact resistance

- Carbon-glass hybrid for cost optimization

- Custom formulations for unique requirements

Advanced Resin Systems

- Industry standard for high-performance applications

- Excellent adhesion to carbon fiber

- Temperature resistance: -50°C to 120°C

- Low shrinkage during curing

- Superior mechanical properties

- Advanced formulations developed with 3M Aerospace

- Enhanced compressive strength and wear resistance

- Extremely low water absorption rate for long-term durability

- Improved impact resistance

- Optimized for filament winding processes

Crafting Precision Driveshafts

The Challenges of Carbon Fiber Driveshaft Manufacturing

- Dimensional Precision: ±0.1mm tolerance for critical fit areas

- Balanced Construction: Uniform wall thickness and fiber distribution

- Bond Integrity: Strong adhesion between carbon fiber and metal components

- Dynamic Balance: G2.5 balance standard for vibration-free operation

- Quality Consistency: Reproducible performance across production runs

Advanced Manufacturing Processes

1. Precision Filament Winding

- Computer-controlled winding machines with 0.01mm precision

- Multi-axis winding capability for complex geometries

- Variable angle winding (15°-85°) for optimal strength distribution

- Constant tension control (±5N) for uniform fiber placement

- In-line resin mixing with precise ratio control

- Temperature-stabilized resin delivery system

- Real-time viscosity monitoring

- Automated quality control for resin content

2. Curing and Forming Excellence

- Custom-designed ovens with ±1°C temperature control

- Programmable heating/cooling profiles for optimal resin curing

- Vacuum-assisted curing for minimal void content

- Pressure monitoring during curing process

- Stress-relief annealing for dimensional stability

- Precision machining for critical mounting surfaces

- Surface finishing for corrosion protection

- Ultrasonic inspection for internal quality verification

3. Quality Control and Testing

- Ultrasonic testing for void detection (<1% void content)

- X-ray inspection for fiber alignment verification

- Acoustic emission testing for bond integrity

- Thermal imaging for uniform curing verification

- Torsional stiffness testing (per ASTM D5379)

- Fatigue life testing (10 million+ cycles)

- Impact resistance testing (per ISO 179)

- Environmental exposure testing (salt spray, UV, temperature cycling)

Our Customization Process

Step 1: Application Analysis

- Vehicle Specifications: Make, model, year, and powertrain configuration

- Performance Goals: Horsepower, torque, and intended use (street, track, or both)

- Packaging Constraints: Length, diameter, and clearance limitations

- Safety Requirements: SFI certification needs and operating parameters

- Budget Considerations: Material selection and manufacturing complexity

Step 2: Engineering Design

- 3D CAD Modeling: Parametric design with full associativity

- Finite Element Analysis: Structural integrity verification under operating conditions

- Computational Fluid Dynamics: Aerodynamic optimization for minimal drag

- Critical Speed Analysis: Calculation of safe operating RPM range

- Design for Manufacturing: Production optimization from initial concept

Step 3: Prototyping and Validation

- Rapid Prototyping: 3D printed molds for quick design validation

- Fit Testing: Verification of mounting points and vehicle integration

- Performance Testing: Torsional stiffness, fatigue life, and balance verification

- On-Vehicle Testing: Real-world validation on test vehicles

Step 4: Production and Quality Assurance

- Precision Manufacturing: State-of-the-art filament winding and curing equipment

- In-Process Inspection: Automated quality checks during production

- Dynamic Balancing: G2.5 balance standard (per ISO 1940)

- Final Testing: 100% performance verification before shipment

- Traceability: Complete production documentation and batch tracking

Quality Standards: Certifications You Can Trust

International Quality Certifications

- Quality management system certification

- Process approach with risk-based thinking

- Continuous improvement methodology

- Customer satisfaction monitoring

- Performance driveshaft safety standard

- Static and cyclic torque testing requirements

- Material and construction specifications

- Quality control and traceability requirements

- Environmental management system

- Sustainable manufacturing practices

- Waste reduction and energy efficiency

- Environmental performance monitoring

Performance and Safety Standards

- Length tolerance: ±0.5mm

- Diameter tolerance: ±0.1mm

- Wall thickness variation: <5%

- Mounting surface flatness: 0.05mm/m

- ISO 1940 G2.5 balance quality

- Maximum residual unbalance: 2 g·mm/kg

- Operating speed range: Up to 12,000 RPM

- Vibration testing per SAE J1926

- Torsional stiffness: 18,000 N·m/° minimum

- Ultimate torque capacity: 2,000 N·m minimum

- Fatigue life: 10 million cycles at 70% load

- Temperature range: -50°C to 120°C

OEM-Specific Requirements

- BMW: GS 97005 (drivetrain components), GS 93003 (composite materials)

- Porsche: PSB 6001 (performance components), PSB 6002 (quality requirements)

- Mercedes-Benz: DBL 7700 (drivetrain systems), DBL 7701 (material specifications)

- Audi: TL 52000 (composite components), TL 52001 (testing requirements)

Why Choose Xiamen Goldcattle?

Performance Comparison

|

Performance Metric

|

Industry Standard

|

Our Capability

|

Improvement

|

|

Weight Reduction

|

40-50%

|

60-70%

|

33% better

|

|

Torsional Stiffness

|

15,000 N·m/°

|

18,000 N·m/°

|

20% higher

|

|

Fatigue Life

|

5 million cycles

|

10 million cycles

|

100% longer

|

|

Balance Quality

|

G6.3

|

G2.5

|

60% improvement

|

|

Production Lead Time

|

8-12 weeks

|

4-6 weeks

|

50% faster

|

Design and Engineering Expertise

- Composite Materials: PhD-level material scientists with 15+ years of experience

- Drivetrain Engineering: Experts in power transmission systems and performance optimization

- Manufacturing Technology: Engineers specializing in advanced composite manufacturing

- Testing and Validation: Specialists in performance testing and certification

Custom Solutions for Every Need

- High-Performance Vehicles: Track-focused designs with maximum stiffness

- Luxury Cars: Lightweight solutions that enhance both performance and refinement

- Electric Vehicles: Optimized for efficiency and reduced rotational mass

- Motorsports Applications: SFI-certified driveshafts for racing use

- Industrial Machinery: Custom solutions for specialized equipment

Case Study: Supercar Drivetrain Transformation

Client Challenge

- Reduce rotational mass by 65% compared to their current aluminum driveshaft

- Increase torsional stiffness by 30% for more precise power delivery

- Withstand over 1,500 horsepower and 1,200 lb-ft of torque

- Meet strict packaging constraints in their mid-engine layout

- Achieve SFI 43.1 certification for track use

Our Solution

Results

Advanced Applications: Beyond Traditional Driveshafts

High-Performance Racing Applications

- Formula Racing: Ultra-lightweight designs for maximum acceleration

- Endurance Racing: Reliable performance for 24-hour races

- Drag Racing: Instantaneous power delivery for quick launches

- Rally Racing: Durable construction for rough terrain

- SFI 43.1 Certification: For safety and performance assurance

- Extreme Torque Capacity: Up to 2,000 lb-ft of torque handling

- High RPM Capability: Safe operation up to 12,000 RPM

- Quick-Change Design: Rapid replacement during pit stops

Electric Vehicle Optimization

- Efficiency Enhancement: Reduced rotational mass improves range by 3-5%

- NVH Improvement: Superior vibration damping for quieter operation

- ** Packaging Flexibility**: Custom shapes to fit EV architectures

- Regenerative Braking: Enhanced responsiveness for energy recovery

- Non-Conductive Materials: For electrical safety in high-voltage systems

- Integrated Design: Combined driveshaft and CV joint assemblies

- Lightweight Construction: Minimal mass for maximum efficiency

- Corrosion Resistance: Maintenance-free operation in all environments

Industrial and Marine Applications

- Marine Propulsion: Lightweight shafts for boats and yachts

- Industrial Machinery: High-precision driveshafts for manufacturing equipment

- Renewable Energy: Wind turbine drivetrain components

- Aerospace: Aircraft and helicopter power transmission systems

Technical Challenges and Solutions

Material and Manufacturing Challenges

- Challenge: Maintaining precise fiber orientation during winding

- Solution: Computer-controlled winding machines with closed-loop tension feedback

- Benefit: Consistent stiffness properties and structural integrity

- Challenge: Minimizing air bubbles in the composite structure

- Solution: Vacuum-assisted resin transfer and pressure curing

- Benefit: Improved strength and fatigue resistance

- Challenge: Ensuring strong adhesion between carbon fiber and metal

- Solution: Proprietary surface treatment and bonding process

- Benefit: Reliable performance under extreme torque loads

Installation and Maintenance Best Practices

- Thorough cleaning of mounting surfaces

- Inspection of mating components for wear

- Verification of alignment specifications

- Follow manufacturer-recommended torque values

- Use calibrated torque wrenches

- Recheck after initial break-in period

- Regular inspection for damage or wear

- Periodic rebalancing if performance changes

- Lubrication of universal joints as needed