The answer is: For CNC contour milling, the most commonly used tools are end mills, with square end mills for sharp corners and ball nose end mills for complex 3D profiles. The specific tool selection depends on the geometry requirements, material properties, and surface finish needs.

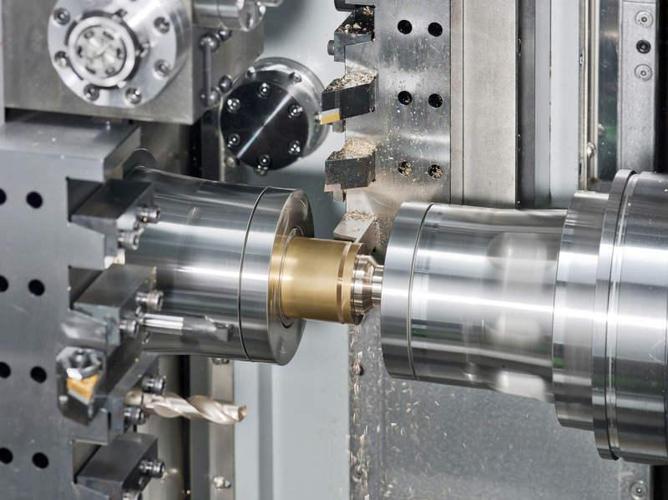

As a CNC machining specialist with over 15 years of experience in precision manufacturing, I’ve worked with countless contour milling applications across industries. From aerospace components to medical devices, the right tool selection is critical for achieving optimal results. Let’s explore the tools and techniques that make contour milling successful.

Understanding Contour Milling

Contour milling is a machining process that creates complex shapes and profiles by moving a cutting tool along a predefined path. This technique is essential for:

- Creating 2D and 3D profiles

- Machining curved surfaces

- Producing intricate geometric shapes

- Achieving high-precision tolerances

The process requires careful consideration of tool geometry, cutting parameters, and machine capabilities to ensure both efficiency and quality.

Primary Tools for Contour Milling

1. Square End Mills

Square end mills are the most versatile tools for contour milling. They feature a flat cutting end with sharp corners, making them ideal for:

- Sharp corner machining: Perfect for 90° angles and rectangular profiles

- Flat surface finishing: Excellent for face milling operations

- Pocketing applications: Creating recessed areas with vertical walls

Key features:

- Flute count: 2, 4, or 5 flutes depending on material and application

- Helix angle: Typically 30°-45° for general purpose machining

- Coating options: TiAlN, AlCrN, or TiCN for improved wear resistance

- Material compatibility: Steel, aluminum, stainless steel, and exotic alloys

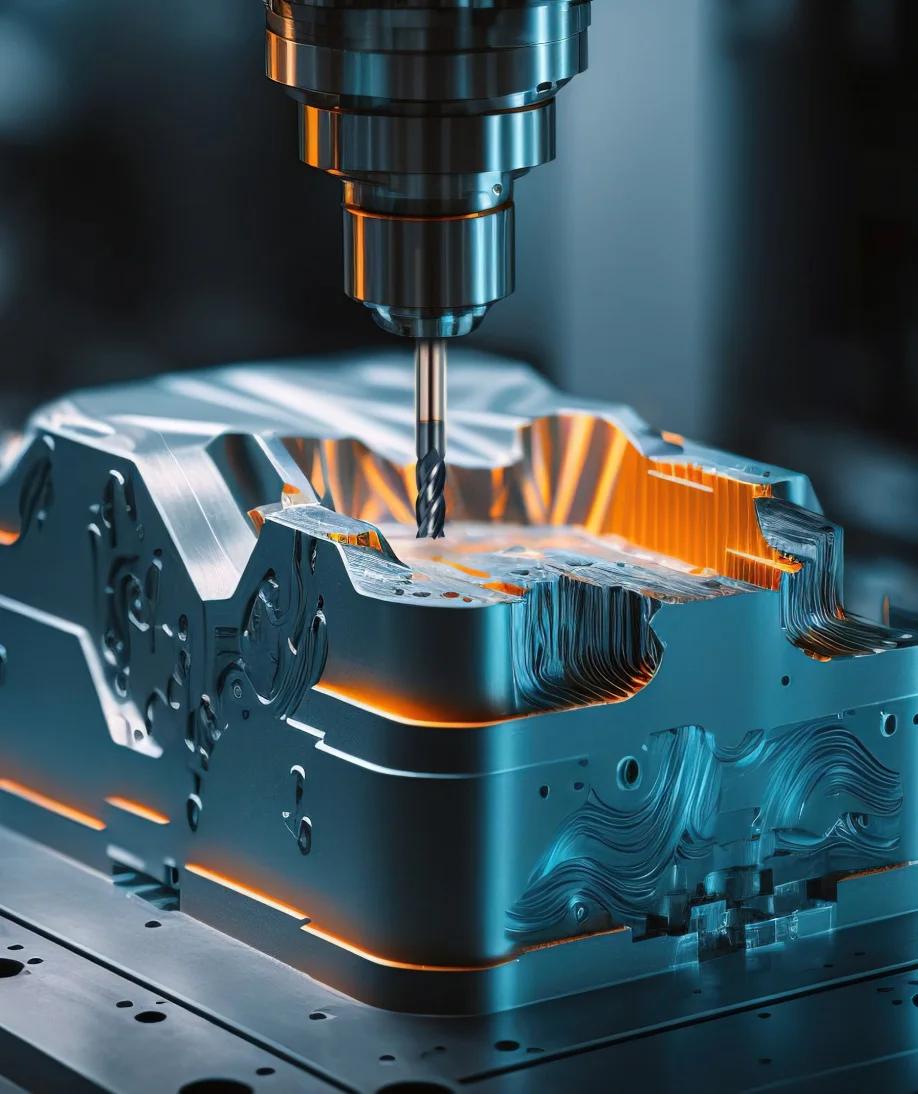

2. Ball Nose End Mills

Ball nose end mills have a hemispherical cutting end, making them indispensable for:

- 3D surface profiling: Complex curved surfaces and organic shapes

- Sculptured surfaces: Mold making and die casting applications

- Contour finishing: Achieving smooth surface finishes

Key features:

- Radius options: From 0.1mm to 25mm and larger

- Flute configuration: 2, 3, or 4 flutes for different materials

- Center cutting capability: Critical for plunge cutting

- High-speed machining: Optimized for HSM applications

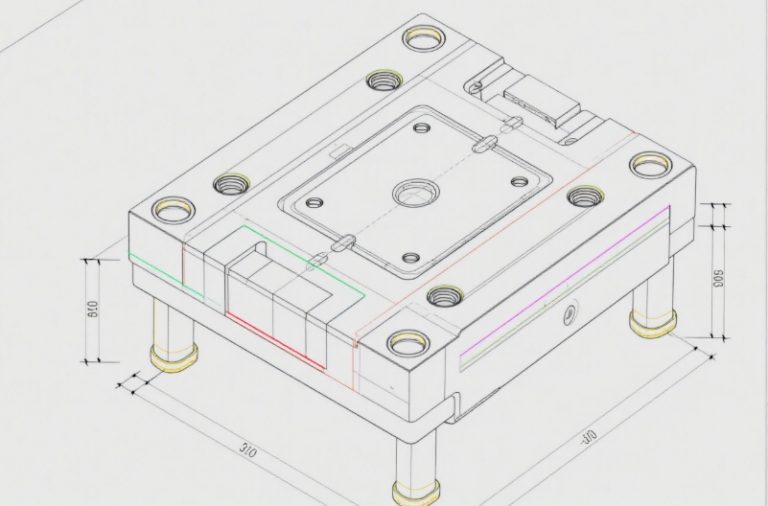

3. Corner Radius End Mills

Corner radius end mills (also known as bull nose end mills) combine features of both square and ball nose tools:

- Radius corners: Rounded edges for increased tool life

- Flat bottom: For precise depth control

- Reduced stress concentration: Prevents corner chipping

Ideal applications:

- Mold cores and cavities: Where corner radii are required

- High-strength materials: Reduces tool wear in hard metals

- Production machining: Improved tool longevity for high-volume runs