2026 Guide to Custom CNC Motorcycle Parts – Precision Machining That Transforms Your Ride

From Aluminum Handlebars to Titanium Exhausts – Xiamen Goldcattle’s 26 Years of Expertise

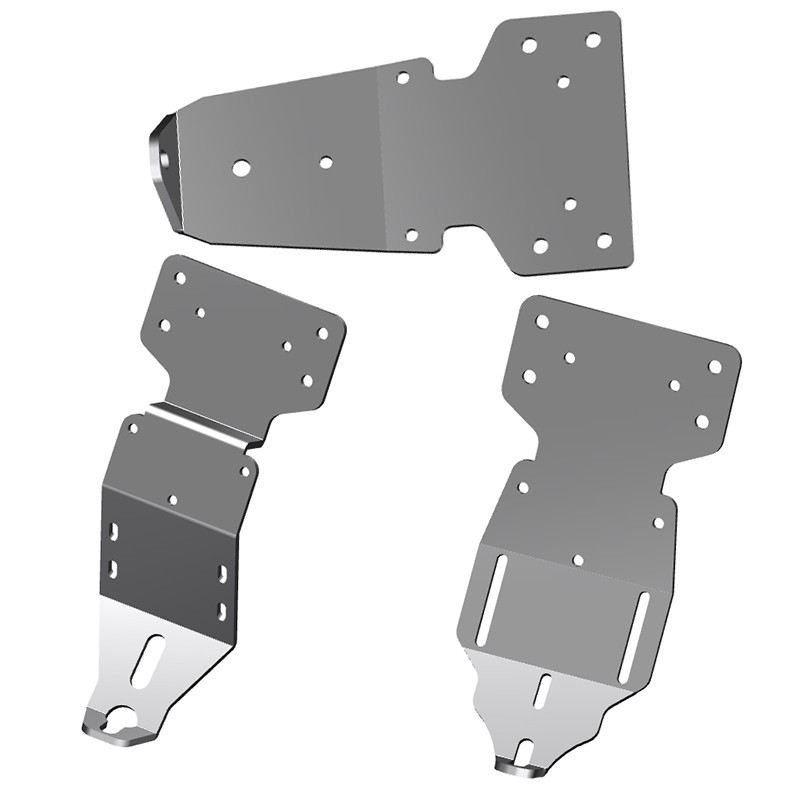

Complete set of custom CNC motorcycle parts showing the transformation possibilities

Ever Felt Your Motorcycle Could Be Better?

Do you ride your beloved Ducati, Harley, or Suzuki GSX-R, but always feel the stock handlebars are too heavy? Or the exhaust isn’t lightweight enough?

When modifying, have you found that off-the-shelf parts have poor precision, causing excessive vibration and short lifespan after installation?

A Real Goldcattle Story

“In 2025, a Harley owner came to us with severely deformed aluminum footpegs. Using 5-axis CNC milling + hard anodizing, we custom-made a lightweight version that reduced weight by 30%. The customer’s feedback? ‘Riding feels as stable as flying.'”

Today, Xiamen Goldcattle takes you deep into the world of custom CNC motorcycle parts – from materials to processes, we’ll solve all your modification challenges in one article.

1. What Are Custom CNC Motorcycle Parts?

CNC (Computer Numerical Control) machining uses pre-programmed computer software to control machine tools that precisely shape raw materials into custom motorcycle parts.

Common custom CNC motorcycle parts include:

- Handlebars and risers

- Footpegs and controls

- Exhaust systems and heat shields

- Brake calipers and rotors

- Chain guards and sprocket covers

- Frame components and brackets

Goldcattle Advantage

“We use Mastercam programming + Haas 5-axis machines. From your drawing to finished product, we deliver in just 7-15 days with tolerance control of ±0.005mm and Ra0.8μm mirror finish.”

CNC machine precisely machining a custom motorcycle component

Stock vs Custom CNC Motorcycle Parts

| Feature | Stock Parts | Custom CNC Parts |

|---|---|---|

| Weight | Heavy (standard materials) | Lightweight (aluminum/titanium) |

| Precision | ±0.1mm tolerance | ±0.005mm tolerance |

| Customization | Limited options | Unlimited design freedom |

| Performance | Standard specifications | Optimized for your needs |

2. Why Do Motorcycle Enthusiasts Need Custom CNC Parts?

The Pain Points of Stock and Off-the-Shelf Parts

Stock Parts Issues

- • Too heavy, affecting handling

- • Expensive OEM pricing

- • Doesn’t match modification style

Aftermarket Copycat Problems

- • Low precision, poor fitment

- • Prone to deformation and corrosion

- • Inconsistent quality control

Performance Upgrade Needs

- • Lightweighting for better performance

- • Improved heat dissipation

- • Enhanced durability and wear resistance

The Benefits of Custom CNC Motorcycle Parts

| Benefit | Description | Goldcattle Example |

|---|---|---|

| Lightweighting | Aluminum/titanium alloys reduce weight by 20-40% | Custom Harley handlebars, weight reduced by 0.8kg |

| Durability | Surface treatments like DLC coating enhance lifespan | Titanium exhaust system, doubled lifespan |

| Personalization | Any color, texture, or size to match your style | Customer-specified laser engraved logo |

| Performance | Precise tolerances reduce vibration and improve handling | Sprocket cover, smoother riding experience |

Another Real Success Story

“A Suzuki GSX-R owner told us that after installing our CNC aluminum brake rotors, his braking distance was reduced by 15%. The precision machining eliminated vibration and improved overall stopping power.”

3. Popular Materials & Processes for Custom CNC Motorcycle Parts

Recommended Materials

6061/7075 Aluminum Alloy

Lightweight, easy to machine, excellent strength-to-weight ratio

Ideal for: Handlebars, wheels, brackets, covers

TC4 Titanium Alloy

Ultra-lightweight, high strength, corrosion resistant

Ideal for: Exhaust systems, fasteners, high-stress components

304/316 Stainless Steel

Rust resistant, durable, food-grade quality

Ideal for: Gas tank caps, exhaust tips, hardware

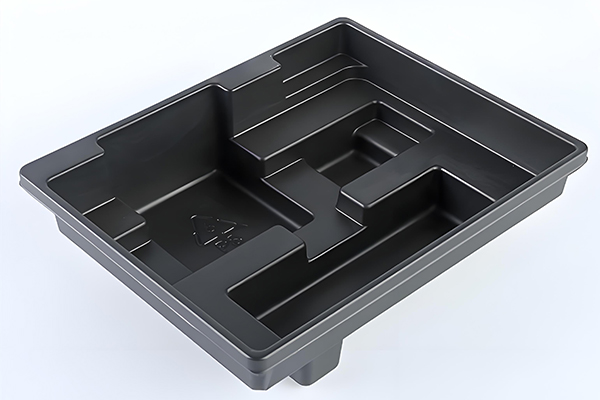

Material comparison: Titanium (left) vs Aluminum (right) for motorcycle parts

Key Machining Processes

CNC Turning

For cylindrical parts like handlebars, exhaust pipes

CNC Milling

For complex shapes with cavities and contours

Wire EDM

For precision holes and intricate details

Surface Finishing

Anodizing, sandblasting, plating, painting

Goldcattle Custom CNC Process

Goldcattle Technical Advantage

“We use cryogenic cooling + AI monitoring to avoid thermal deformation in stainless steel. Tolerance stability is maintained at ±0.005mm throughout production.”

4. Real Cases: How Goldcattle Customizes Perfect Motorcycle Parts

Harley Davidson Customization

A Harley owner wanted to reduce weight and improve off-road performance. We used 3D scanning of the original footpegs and created a custom titanium version using 5-axis CNC milling.

Results

- • Weight reduction: 35%

- • Improved grip and durability

- • Better vibration damping

- • Customer feedback: “Off-roading feels much more stable”

Custom CNC machined titanium footpeg for Harley Davidson

Off-Road Motorcycle Fuel Cap

Custom CNC aluminum fuel cap for off-road motorcycle

An off-road enthusiast needed a more durable fuel cap that wouldn’t leak during rough riding. We designed and CNC machined an aluminum cap with enhanced sealing and impact resistance.

Key Features

- • Leak-proof design

- • Impact-resistant construction

- • Aesthetic custom finish

- • Passed rigorous drop testing

Racing Team Sprocket Project

A professional racing team needed high-precision sprockets for their competition bikes. We produced a batch of CNC machined sprockets with positional accuracy of 0.003mm.

Performance Results

- • Zero failures during races

- • Improved power transfer efficiency

- • Consistent chain alignment

- • Extended component lifespan

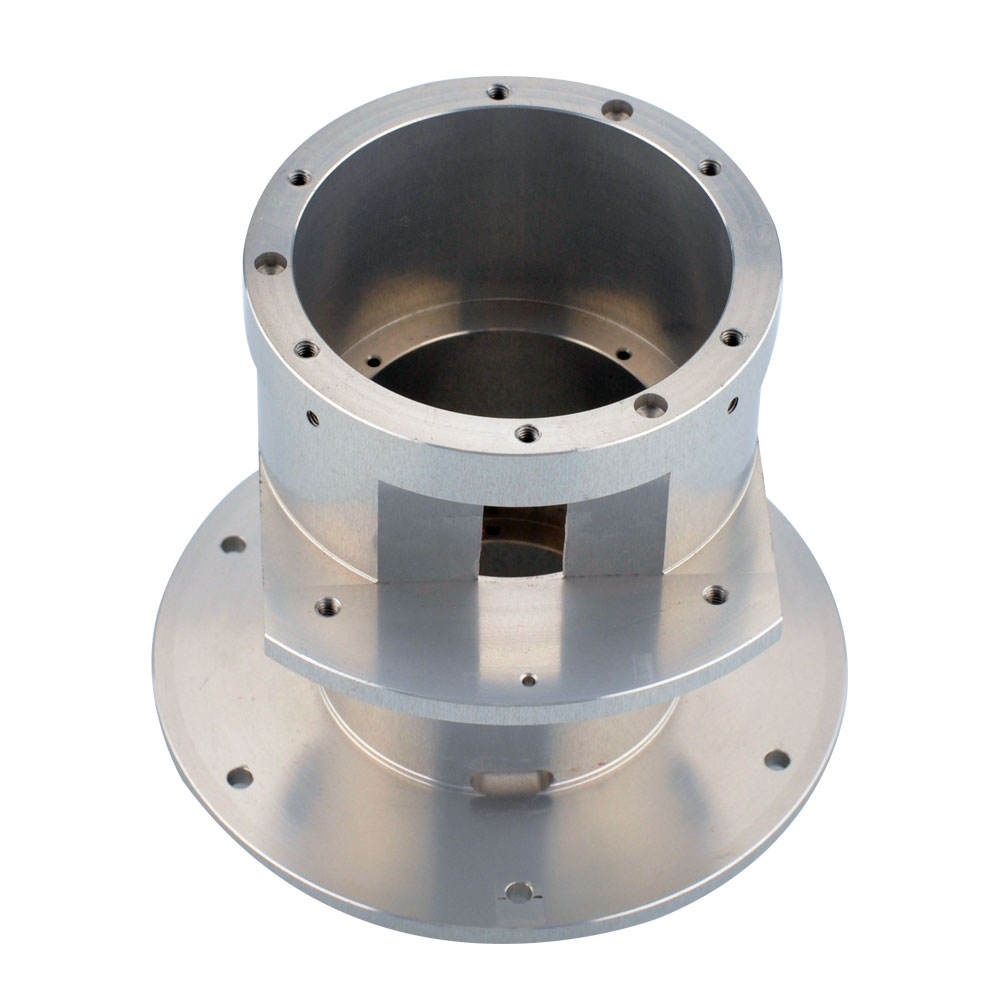

Precision CNC machined sprocket components for racing motorcycles

5. How to Choose a Reliable Custom CNC Motorcycle Parts Supplier?

Choosing the right supplier is crucial for getting high-quality custom CNC motorcycle parts. Here are the 5 key criteria:

Experience & Certifications

At least 10 years of experience, ISO/AS9100 certifications, and proven motorcycle industry expertise.

Equipment & Facilities

5-axis CNC machines, temperature-controlled workshops, and comprehensive quality control equipment.

Material Supply Chain

Certified raw materials from reputable suppliers with complete traceability.

DFM Feedback

Free design for manufacturing optimization and professional engineering advice.

Lead Time & After-sales

7-15 day delivery, 1-3 year warranty, and responsive customer support.

Goldcattle’s temperature-controlled workshop ensures precision machining

Why Choose Xiamen Goldcattle?

“With 26 years of experience, 1000㎡ temperature-controlled facility, free DFM analysis + sample testing, we’re your trusted partner for custom CNC motorcycle parts.”

6. Frequently Asked Questions

Ready to Transform Your Ride?

Custom CNC motorcycle parts aren’t just about upgrading hardware—they’re about unlocking your riding passion and making your bike truly one-of-a-kind.

Get Your Free Customization Consultation

Upload your CAD drawing for a fast DFM review and quote. We’ll respond within 24 hours!

Or contact us directly:

Email: charlie@plasticmetalparts.com

WhatsApp/WeChat: +86-18150097490