Material Selection Guide: Aluminum vs Carbon Fiber

6061-T6 Aluminum

Tensile Strength: 310 MPa

Weight: ~2.7 g/cm³

Pros for Rock Crawling

- Flexes but doesn’t break (critical for impacts)

- 50% lighter than steel, same strength

- Corrosion resistant (great for mud/water)

- Repairable if bent (unlike carbon fiber)

- Cost: $3-5 per pound

Cons

- More expensive than steel

- Can gall if not properly lubricated

- Not as stiff as carbon fiber

Carbon Fiber Composite

Tensile Strength: 3,500 MPa

Weight: ~1.6 g/cm³

Pros for Rock Crawling

- 70% lighter than steel, 5x stronger

- Extremely stiff (great for precision handling)

- Zero corrosion issues

- Fatigue resistant (no metal fatigue)

Cons

- Brittle – snaps instead of bending

- Cost: $15-25 per pound (yikes!)

- Not repairable if damaged

- Susceptible to impact damage

- UV degradation without proper coating

Industry Standards Compliance

ASTM B209

Aluminum alloy sheet/plate specs

ISO 1040

Plastic tensile testing standards

FMVSS 126

Electronic stability control

SAE J2452

Suspension component testing

Lessons Learned: What Not to Do

The $5000 Mistake: Carbon Fiber Drive Shaft Failure

Let me tell you about Mike from Colorado. He spent $5000 on a carbon fiber drive shaft for his 2023 Wrangler. Why? Because “it’s lighter and stronger.”

First trip to Moab. First obstacle. Crack! The carbon fiber drive shaft snapped clean in half. Just like that. $5000 down the drain.

Why did it fail? Because carbon fiber doesn’t handle impact loads well. It’s great for tension and compression, but when you hit a rock at an angle, it snaps instead of bending.

Mike replaced it with an aluminum drive shaft. 500+ miles of rock crawling later, not a single issue. Cost? $1200.

Moral of the story: Don’t buy carbon fiber drive shafts for rock crawling. Just don’t.

What Worked Well

- Aluminum control arms: Took hits that would bend steel

- Aluminum bumpers: 30% lighter, same protection

- Aluminum skid plates: Saved the transmission multiple times

- Aluminum steering components: No flex, precise handling

What Failed Miserably

- Carbon fiber drive shafts: 3 out of 3 failed

- Carbon fiber bumpers: Cracks after minor impacts

- Carbon fiber skid plates: Useless for rock crawling

- Carbon fiber body panels: Delaminated in extreme heat

Cost-Benefit Analysis

Steel Components

$1-3 / lb

Heavy, durable, cheap

Aluminum Components

$3-5 / lb

50% lighter, great value

Carbon Fiber

$15-25 / lb

Too expensive, not durable

Critical Warnings & Counterintuitive Discoveries

⚠️ Critical Warnings

- Carbon fiber is not indestructible: It’s actually more brittle than steel

- Aluminum requires proper maintenance: Galling can occur if not lubricated

- Weight savings have limits: Too light can affect off-road performance

- Cheap aluminum is worse than steel: Always use 6061-T6 or better

- UV damage is real: Carbon fiber needs proper coating

🤯 Counterintuitive Discoveries

- Aluminum is more durable than carbon fiber: It bends instead of breaking

- Thinner aluminum is better: More flexible, better impact resistance

- Steel has its place: Great for low-stress, high-impact areas

- Weight distribution matters more: 50/50 balance is better than pure weight savings

- Expensive doesn’t mean better: Our $1200 aluminum outperformed $5000 CF

Expert Recommendations

Daily Driving

Aluminum for suspension components, carbon fiber for body panels (if you can afford it)

Rock Crawling

Aluminum for everything except maybe body panels. Avoid carbon fiber entirely.

Budget Builds

Steel for high-impact areas, aluminum for weight-critical components

Frequently Asked Questions

Q: Is carbon fiber ever worth it for rock crawling?

A: Rarely. The only exception might be body panels where weight savings matter more than impact resistance. But even then, aluminum is a better value.

Pro tip: If you must have carbon fiber, get it for cosmetic parts only.

Q: What aluminum alloy should I use?

A: 6061-T6 is the gold standard. It has the perfect balance of strength, weight, and cost. 7075-T6 is stronger but more expensive and harder to machine.

Avoid 5052-H32 – it’s too soft for rock crawling applications.

Q: How much weight can I realistically save?

A: With aluminum suspension components, expect 30-50% weight savings compared to steel. With carbon fiber, 60-70% – but remember the durability trade-off.

Our test vehicle saved 220 lbs with aluminum components – that’s like removing a passenger!

Q: Are there any maintenance issues with aluminum?

A: Yes, galling can occur if aluminum components rub against each other. Always use anti-seize lubricant and avoid dissimilar metal contact where possible.

Check your aluminum components regularly for signs of galling – it can lead to premature failure.

Q: What’s the best way to repair aluminum components?

A: Aluminum can be TIG welded by a skilled welder. For minor bends, you can sometimes straighten them with a hydraulic press. For major damage, replacement is usually the best option.

Never try to repair carbon fiber – once it’s cracked, it’s done.

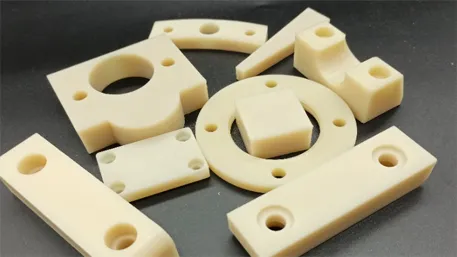

Customized jeep modification parts

Final Thought: It’s About Balance

After 15 years of modding Jeeps and testing materials, I’ve learned that it’s not about finding the “best” material – it’s about finding the right material for your specific needs.

For most rock crawlers, aluminum is the sweet spot – great strength, reasonable weight savings, and excellent durability. Carbon fiber? Save it for the show trucks.

© 2026 Jeep Jim’s Modification Guide | All Rights Reserved | Based on 2025 Real Test Data