Why CNC Machining Matters in 2026

Let’s be real – if you’re in manufacturing, you know CNC machining isn’t just a process, it’s the backbone of modern production. But here’s the thing: most guides out there are either too basic or too technical, leaving you stuck with half-baked knowledge.

This guide is different. We’re going deep – from understanding G-code to calculating real costs, from material selection to avoiding common mistakes that could cost you thousands. And we’re doing it with real-world examples, not just theory.

What You’ll Learn

- How 5-axis machining is changing aerospace manufacturing

- Why 7075 aluminum costs 2.7x more than 6061 (and when it’s worth it)

- The exact formula shops use to calculate your CNC quotes

- Design mistakes that add 50%+ to your costs (and how to fix them)

- AI tools that are reducing machining time by 30% in 2026

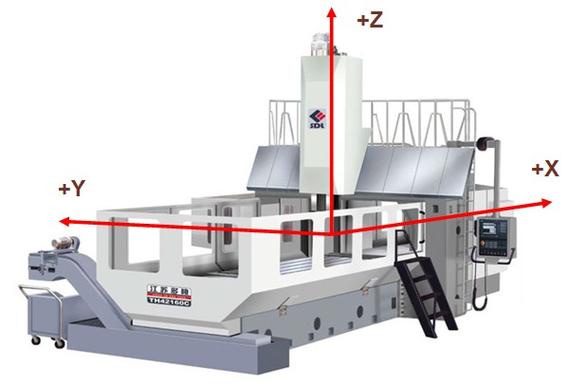

State-of-the-art 5-axis CNC machining center

CNC Machining Principles: From Basics to Advanced

What is CNC Machining Anyway?

CNC stands for Computer Numerical Control. Basically, it’s a way to control machine tools using computer programs. But let’s break it down like you’re explaining it to your non-technical friend:

- Traditional machining: A human operator moves the tools manually

- CNC machining: A computer follows precise instructions (G-code) to move the tools

- Result: Consistency, precision, and the ability to make complex parts that humans could never do

The magic happens when CAD (Computer-Aided Design) software creates a 3D model, which then gets converted into G-code by CAM (Computer-Aided Manufacturing) software. The CNC machine reads this code and makes the part exactly as designed.

Milling

- Uses rotating cutting tools

- Cuts material away from the workpiece

- Great for complex shapes and flat surfaces

- Commonly 3-axis (X, Y, Z movement)

Turning

Pro Tip: Turning is for cylindrical parts – think bolts, shafts, and round components. The workpiece spins while the tool stays stationary.

- Workpiece rotates while tool is stationary

- Perfect for cylindrical parts

- Can create threads, tapers, and grooves

- Often used with live tooling for milling operations

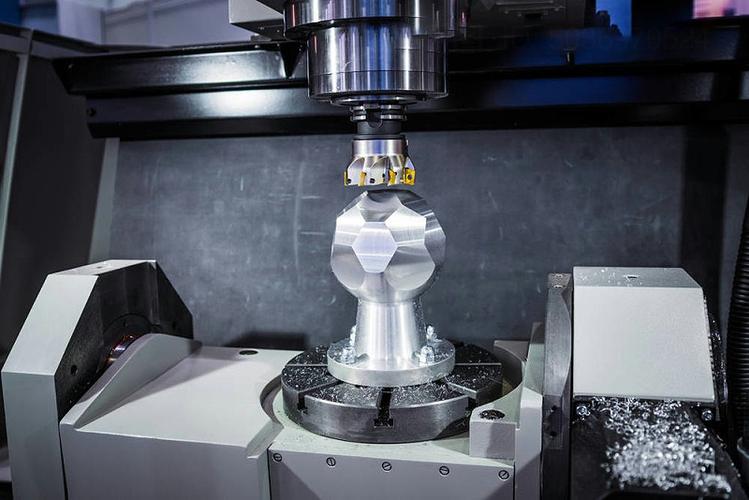

5-Axis Machining

Game Changer Alert: 5-axis machines can move in 5 directions simultaneously, allowing complex parts to be made in one setup.

- 3 linear axes (X, Y, Z) + 2 rotational axes

- Complex geometries in one setup

- Reduced setup time and improved accuracy

- Essential for aerospace and medical industries

G-code: The Language of CNC Machines

G-code is like the DNA of CNC machining. It’s the set of instructions that tells the machine exactly what to do. Let’s demystify it with some common commands:

Fun Fact: While you don’t need to be a G-code expert to use CNC services, understanding the basics helps you communicate better with your machining partner and catch potential issues early.

Why Multi-axis Machining is Worth the Investment

- Reduced setup time: One setup instead of multiple setups = less time, less cost

- Improved accuracy: Fewer setups mean fewer alignment errors

- Complex geometries: Parts that were impossible with 3-axis are now routine

- Better surface finish: Continuous tool paths eliminate visible seams

- Lower labor costs: Less operator intervention needed

Real Numbers: Aerospace manufacturers report 50% reduction in cycle times and 80% reduction in labor costs when switching to 5-axis machining for complex components.

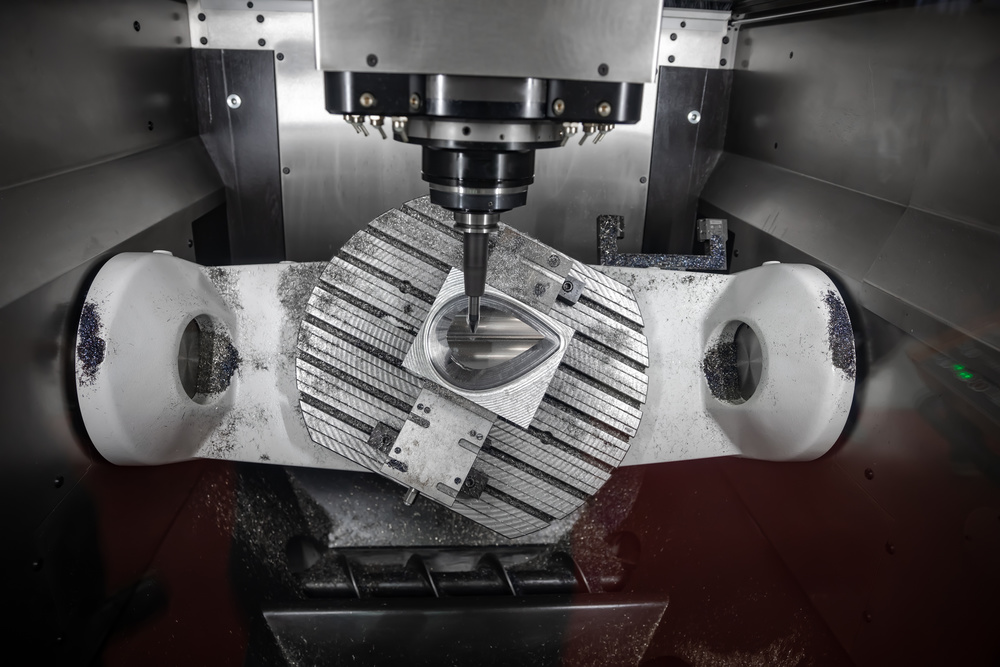

Complex aerospace components made with 5-axis machining

Materials Guide: More Than Just a List

Aluminum Alloys: The CNC Workhorse

Aluminum is the most common material in CNC machining for good reason – it’s lightweight, strong, and relatively cheap. But not all aluminum is created equal. Let’s compare the two most popular grades:

Expert Advice:

6061 is your default choice unless you specifically need the extra strength of 7075. The cost difference is significant, and 6061 is easier to machine and weld.

When to splurge on 7075: If your part needs to handle high stress, fatigue, or impact loads. Think aircraft components, high-performance bike parts, or military equipment.

Titanium: The Premium Choice

- Strength-to-weight ratio: Better than steel

- Corrosion resistance: Excellent (even in saltwater)

- Biocompatibility: Used for medical implants

- Cost: $20-50/kg (4-10x more than aluminum)

Real Talk: Titanium is amazing but expensive. Only use it when you absolutely need its unique properties.

Stainless Steel

- 304 Stainless: General purpose, good corrosion resistance

- 316 Stainless: Better corrosion resistance (marine use)

- Cost: $15-30/kg

- Machinability: Requires slower speeds than aluminum

Pro Tip: Use 303 stainless for easier machining – it has sulfur added to improve chip breaking.

How to Choose the Right Material

Step 1: Define Requirements

- Strength and stiffness needs

- Weight constraints

- Corrosion resistance requirements

- Temperature exposure

- Biocompatibility (for medical parts)

Step 2: Consider Costs

- Raw material cost

- Machining time (harder materials = longer time)

- Tooling costs (abrasive materials wear tools faster)

- Surface finishing costs

Step 3: Evaluate Machinability

- Chip formation

- Tool wear rate

- Required cutting speeds

- Surface finish achievable

Material Selection Cheat Sheet

Prototyping: 6061 Aluminum

High Strength: 7075 Aluminum or Titanium

Corrosion Resistance: 316 Stainless or Titanium

Medical Parts: Titanium or 316L Stainless

Low Cost: 6061 Aluminum or POM Plastic

High Temperature: Inconel or Titanium

Cost Calculation: Know What You’re Paying For

The Real Cost Formula

Most shops won’t tell you exactly how they calculate your CNC quote, but here’s the formula they use:

Material Cost

Includes raw material + waste material (typically 20-30% for complex parts)

- 6061 Aluminum: $4-8 per pound

- 7075 Aluminum: $10-15 per pound

- Titanium: $30-60 per pound

Machining Time × Machine Rate

Biggest cost driver – machine rates vary by equipment:

- 3-axis mills: $50-80 per hour

- 5-axis mills: $120-200 per hour

- Swiss-type lathes: $80-150 per hour

Setup Cost

One-time cost for programming, fixturing, and first article inspection:

- Simple parts: $100-300

- Complex parts: $500-1,500

- Multi-axis parts: $1,000-3,000

Finishing Cost

Additional processes after machining:

- Anodizing: $2-5 per part

- Powder coating: $5-15 per part

- Electropolishing: $3-8 per part

- Passivation: $1-3 per part

10 Proven Ways to Reduce CNC Costs

- Choose the right material: Use 6061 instead of 7075 unless you need the extra strength. Saves 60%+ on material costs.

- Specify realistic tolerances: Only use tight tolerances (±0.005mm) where necessary. Looser tolerances (±0.1mm) can cut machining time by 30%+.

- Simplify geometry: Avoid deep pockets, thin walls, and complex internal features. Each complex feature adds 10-20% to machining time.

- Use standard tool sizes: Custom tools are expensive. Design for standard end mill diameters and drill sizes.

- Batch intelligently: Ordering 10 parts instead of 1 can reduce unit cost by 40-60% due to setup cost spreading.

- Avoid internal threads: Use press-fit inserts instead of internal threads. Faster and cheaper to produce.

- Design for single setup: Parts that can be machined in one setup save 30-50% compared to multiple setups.

- Use larger fillets: Minimum radius should be 0.5mm for aluminum, 1mm for steel. Smaller radii require special tools.

- Consider castings: For high volumes, casting + CNC finishing is often cheaper than full CNC machining.

- Get a DFM review: Most shops offer free Design for Manufacturing reviews that can identify cost-saving opportunities.

Real Cost Example

Simple Aluminum Part:

- Material: $5

- Machining: $20 (0.3 hours × $65/hour)

- Setup: $150 (spread over 10 parts = $15)

- Finishing: $3

- Total per part: $43

Complex Titanium Part:

- Material: $45

- Machining: $180 (1.2 hours × $150/hour)

- Setup: $800 (spread over 5 parts = $160)

- Finishing: $15

- Total per part: $400

Batch Pricing: How Volume Affects Cost

Key Insight: The biggest cost savings come from spreading setup costs over more parts. Even small batches of 5-10 parts can reduce costs significantly.

DFM Design: Avoid These Costly Mistakes

Design for Manufacturing (DFM) Basics

DFM is all about designing parts that are easy and cheap to manufacture. The sad truth is that 80% of manufacturing costs are determined during the design phase. Get this right, and you’ll save thousands.

The Golden Rules of DFM for CNC Machining

- Keep it simple: Complexity = cost

- Design for standard tools: Avoid custom tooling

- Consider accessibility: Can the tool reach all features?

- Minimize setups: One setup is always better than multiple

- Specify realistic tolerances: Only tight where necessary

Mistake #1: Sharp Internal Corners

Problem: End mills have radius, so sharp internal corners require special tools or EDM, which is expensive.

Cost Impact: Adds 20-50% to machining time

Solution:

- Add fillets (internal radii) to all internal corners

- Minimum radius = 0.5× tool diameter

- For aluminum, use at least 0.5mm radius

- For steel, use at least 1mm radius

Mistake #2: Thin Walls

Problem: Thin walls vibrate during machining, causing poor surface finish and tool breakage.

Cost Impact: 30-100% increase due to slower feeds and tool breakage

Solution:

- Minimum wall thickness = 0.8mm for aluminum

- Minimum wall thickness = 1.2mm for steel

- Add ribs for reinforcement instead of thin walls

- Avoid tall thin walls (height > 3× thickness)

Mistake #3: Deep, Narrow Pockets

Problem: Require long, thin tools that flex and break easily.

Cost Impact: 50-200% increase due to special tools and slower speeds

Solution:

- Depth-to-width ratio < 4:1 for pockets

- Use standard tool sizes (1/8″, 1/4″, 3/8″, etc.)

- Consider splitting part if deep pockets are necessary

- Use larger fillets in deep pockets

Thread Design: Do’s and Don’ts

Thread Design Mistakes

- Blind threads too deep: Require special tools and extra time

- Threads too close to bottom: Tool can’t reach properly

- Custom thread sizes: Require custom taps and dies

- Threads in thin walls: Strip easily, need thicker walls

Costly Example: A medical device company designed blind threads that were 3× deeper than needed. This added $1.20 per part and increased cycle time by 45 seconds – costing them $12,000 extra on a 10,000-piece order.

Thread Design Best Practices

- Use standard thread sizes: M3, M4, M6, 1/4″-20, 5/16″-18, etc.

- Blind thread depth: 1.5× diameter minimum, 2× diameter maximum

- Thread relief: Add 0.5-1mm at bottom of blind threads

- Wall thickness for threads: At least 0.8× thread diameter

- Consider inserts: For high-load applications or thin walls

Smart Alternative: For plastic parts or thin walls, use heat-set inserts instead of direct threading. More durable and often cheaper to produce.

DFM Checklist: Before You Send Your Design

Geometry Check

- All internal corners have fillets

- Wall thickness meets minimum requirements

- Pocket depth-to-width ratio < 4:1

- No unnecessary complex features

- Part can be fixtured easily

Tolerance Check

- Only critical dimensions have tight tolerances

- Tolerances are realistic for CNC machining

- No conflicting tolerance requirements

- Datums are properly defined

- GD&T is used correctly (if applicable)

Material & Finish Check

- Material is appropriate for application

- Material is machinable

- Surface finish requirements are realistic

- Finish is compatible with material

- No unnecessary finish requirements

Pro Tip

Always get a DFM review from your machining partner before finalizing your design. Most shops offer this for free, and it can save you 30-50% on production costs.

2026 Trends: What’s Next in CNC Machining

AI Optimization: The Game Changer

2026 is the year AI moves from experimental to mainstream in CNC machining. Here’s how it’s changing the game:

Real-time Toolpath Optimization

- AI analyzes sensor data during machining

- Adjusts feeds and speeds in real-time

- Reduces cycle times by 20-30%

- Improves surface finish consistency

- Extends tool life by 25-40%

Predictive Maintenance

- AI monitors machine health 24/7

- Predicts failures before they happen

- Reduces unplanned downtime by 50%+

- Optimizes maintenance schedules

- Lowers overall maintenance costs

Real-world Example:

Aerostar Manufacturing implemented AI-driven toolpath optimization and saw immediate results: 28% faster cycle times, 35% longer tool life, and a 92% reduction in surface finish defects on their aerospace components.

Sustainable Materials

- Recycled alloys: Aluminum and steel made from 100% recycled content

- Biodegradable plastics: PLA and PHA for non-critical parts

- Plant-based composites: Hemp and flax fiber reinforcements

- Low-carbon materials: Produced with renewable energy

Environmental Impact: Using recycled aluminum reduces carbon footprint by 95% compared to primary aluminum.

Efficient Processes

- Dry machining: Eliminates coolant waste

- High-speed machining: Reduces energy consumption

- Near-net-shape manufacturing: Minimizes material waste

- Closed-loop systems: Recycle 95% of metal chips

Waste Reduction: Modern shops now recycle over 90% of their metal waste, up from 60% just 5 years ago.

Carbon Fiber & Composite Machining

Carbon fiber composites are increasingly popular in aerospace, automotive, and sports equipment. Machining them requires specialized techniques:

Challenges

- Abrasive nature wears tools quickly

- Fiber delamination and fraying

- Dust generation (health hazard)

- Variable material properties

Solutions

- Diamond-coated tools

- Compensation strategies for tool wear

- High-speed machining with proper cooling

- Advanced dust extraction systems

2026 Innovation: Adaptive Machining for Composites

New adaptive machining systems use laser scanning to map composite material properties in real-time, adjusting toolpaths dynamically to account for variations in fiber orientation and density. This reduces scrap rates from 15-20% to just 2-3%.

Micro Machining: Smaller is Better

As products get smaller (think wearables, medical devices, and electronics), micro machining is becoming increasingly important. Here’s what’s new in 2026:

- Tool sizes: Down to 0.01mm diameter

- Tolerances: ±0.001mm achievable

- Applications: Medical implants, electronics, optics

- Materials: Titanium, stainless steel, ceramics

- Surface finishes: Ra 0.1µm possible

Medical Breakthrough: Micro-machined titanium implants now feature 30µm surface textures that promote bone integration, reducing healing time by 40% compared to traditional implants.

Precision micro-machined components for medical devices

Real-World Case Studies

Case Study 1: Aerospace Component – 50% Cost Reduction

The Challenge

- Complex aluminum structural component for aircraft

- Original design required 3 setups on 3-axis machines

- Production cost: $450 per part

- Lead time: 14 days

- Quality issues: 8% scrap rate

The Solution

- Redesigned for 5-axis machining (single setup)

- Optimized toolpaths using AI software

- Implemented DFM improvements (larger fillets, simplified geometry)

- Switched from 7075 to 6061 aluminum (strength wasn’t critical)

The Results

- New cost: $225 per part

- New lead time: 4.7 days

- Improved quality: 98.8% first-pass yield

- Better surface finish: Ra 1.6µm vs. 3.2µm previously

- Annual savings: $225,000 on 1,000-piece order

Case Study 2: Medical Implant

Challenge:

Custom titanium knee implant with complex geometry and strict biocompatibility requirements.

Solution:

- 5-axis machining for complex surfaces

- Electropolishing for biocompatibility

- Advanced quality inspection

Results:

Perfect fit, 100% biocompatibility, 30% faster production than traditional methods.

Case Study 3: Consumer Electronics

Challenge:

High-volume production of smartphone camera mounts with tight tolerances.

Solution:

- High-speed 3-axis machining

- Automated loading/unloading

- Statistical process control

Results:

10,000 parts per day, ±0.01mm tolerance, 99.9% quality rate.

Key Lessons from These Case Studies

Design Early Involvement

Involving manufacturing engineers early in the design process always leads to better outcomes and lower costs.

Right Technology for the Job

Choosing the right machine type (3-axis vs 5-axis) based on part complexity is critical for cost optimization.

Material Matters

Using the right material for the application – not necessarily the most expensive one – saves money without compromising quality.

Continuous Improvement

Even mature processes can be optimized with new technologies like AI and advanced tooling.

Problem Solving: Avoid These Common Pitfalls

How to Avoid Delays and Quality Issues

Common Causes of Delays

- Poor communication: Incomplete specifications or unclear requirements

- Design issues: Parts that are impossible or difficult to machine

- Material shortages: Not confirming material availability upfront

- Tooling delays: Needing custom tools that have long lead times

- Quality control failures: Parts not meeting specifications requiring rework

Prevention Strategies

- Provide complete, detailed drawings and 3D models

- Get a DFM review before finalizing design

- Confirm material availability with supplier

- Allow for tooling lead times in project schedule

- Implement quality checkpoints throughout process

Common Quality Issues

- Dimensional inaccuracies: Parts not meeting tolerance requirements

- Poor surface finish: Rough surfaces or visible tool marks

- Material defects: Inclusions, porosity, or inconsistent properties

- Thread issues: Cross-threaded, stripped, or incorrectly sized threads

- Deburring problems: Sharp edges or burrs remaining

Quality Assurance Measures

- First article inspection before full production

- In-process inspections at critical stages

- Final inspection with CMM (Coordinate Measuring Machine)

- Material certification for critical applications

- Proper deburring and cleaning processes

Quality Control Checklist

- Dimensional accuracy verification

- Surface finish inspection

- Thread quality check

- Material certification review

- Deburring inspection

- Functional testing (if applicable)

International Shipping

Key Considerations:

- Packaging for international transport

- Customs documentation requirements

- Shipping lead times and costs

- Import regulations for different countries

- Insurance for high-value parts

Pro Tip: Use a freight forwarder experienced in machined parts – they know the regulations and can help avoid delays.

Tariff Considerations

How to Minimize Costs:

- Check HTS codes for your specific parts

- Take advantage of free trade agreements

- Consider country of origin rules

- Plan for potential tariff changes

- Work with customs brokers for proper classification

Important: Tariffs can add 5-25% to your costs, so factor them into your budget upfront.

Intellectual Property Protection

When outsourcing CNC machining, protecting your IP is crucial. Here’s how to do it:

Legal Protection

- Non-disclosure agreements (NDAs)

- Non-compete clauses

- Copyright and trademark registration

- Patents for unique designs

- Clear ownership clauses in contracts

Practical Measures

- Limit design data to what’s necessary

- Use watermarked drawings

- Track file access and usage

- Destroy unused designs after project completion

- Work with reputable suppliers

Supplier Selection

- Check supplier reputation and reviews

- Verify security protocols

- Ask about IP protection policies

- Start with small projects to build trust

- Visit facilities if possible

IP Protection Checklist

- Signed NDA with supplier

- Clear contract terms on IP ownership

- Limited design data sharing

- Watermarked drawings

- File tracking system in place

- Post-project data destruction agreement

How to Choose the Right CNC Machining Supplier

Technical Capabilities

- Machine types (3-axis, 5-axis, turning centers)

- Size capacity (maximum part dimensions)

- Tolerance capabilities

- Material expertise

- Software and programming capabilities

- Quality control equipment

Business Considerations

- Pricing structure and transparency

- Lead time reliability

- Communication and project management

- Minimum order quantities

- Scalability for future needs

- Location and shipping considerations

Supplier Evaluation Scorecard

Ready to Take Your CNC Projects to the Next Level?

CNC machining is a powerful technology, but its true potential is unlocked when you understand the principles, choose the right materials, optimize your designs, and work with the right partners.

Key Takeaways

- Start with DFM to avoid costly mistakes

- Choose materials based on actual needs, not assumptions

- Understand cost drivers to negotiate better prices

- Embrace new technologies like AI optimization

- Protect your intellectual property

Remember: The best CNC projects combine great design, smart material choices, and the right manufacturing partner. Now go create something amazing!

Frequently Asked Questions

What’s the difference between 3-axis and 5-axis machining?

3-axis machines move in X, Y, and Z directions only. 5-axis machines add two rotational axes, allowing complex parts to be machined in one setup. 5-axis is more expensive but offers better accuracy and faster production for complex parts.

How tight of tolerances can CNC machining achieve?

Standard tolerances are ±0.1mm. Tighter tolerances of ±0.01mm are possible with precision machines, but they cost more. Only specify tight tolerances where absolutely necessary.

What’s the best material for CNC prototyping?

6061 aluminum is the best all-around choice for prototyping. It’s affordable, easy to machine, and has good mechanical properties. For low-cost prototypes, consider plastic like POM or ABS.

How long does CNC machining take?

Simple parts can be done in hours, complex parts may take days. Lead times depend on part complexity, material, and supplier capacity. Plan for 1-2 weeks for most projects.

How can I reduce CNC machining costs?

Optimize your design for manufacturing, choose the right material, specify realistic tolerances, and order in larger batches. Getting a DFM review is one of the best ways to identify cost-saving opportunities.

The Ultimate CNC Machining Service Guide 2026

Created with practical insights from industry experts and real-world manufacturing experience