Why Your CNC Supplier Matters More Than You Think

Let’s cut to the chase – choosing the wrong CNC supplier can cost you big time. We’re talking missed deadlines, parts that don’t fit, quality issues that ruin your reputation, and costs that spiral out of control.

But here’s the good news: pick the right partner, and it’s like adding a supercharged engineering team to your business. You get precision parts, on-time delivery, competitive pricing, and someone who actually understands your needs.

The Shocking Truth

Did you know that 78% of manufacturing delays are caused by supplier issues? And 62% of quality problems can be traced back to poor supplier selection? Don’t be another statistic.

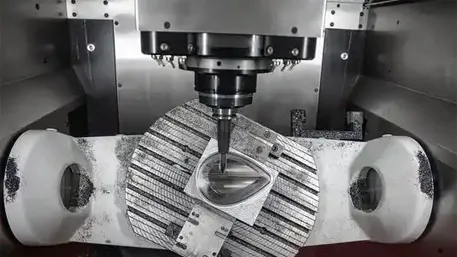

Modern CNC machining facility with precision equipment

CNC Machining Basics: What You Need to Know

What Even Is CNC Machining?

CNC stands for Computer Numerical Control. Basically, it’s a way to control machine tools using computer programs. But let’s break it down like you’re explaining it to your buddy who knows nothing about manufacturing:

- Old-school machining: A guy turns cranks and moves tools by hand

- CNC machining: A computer follows precise instructions (G-code) to move the tools

- Result: Parts that are exactly the same every time, super precise, and way more complex than what humans can make

The magic happens when CAD (Computer-Aided Design) software creates a 3D model, which then gets converted into G-code by CAM (Computer-Aided Manufacturing) software. The CNC machine reads this code and makes the part exactly as designed.

Precision Levels

- Standard tolerance: ±0.1mm (that’s 0.004 inches – super tiny!)

- Precision tolerance: ±0.01mm (0.0004 inches – crazy precise)

- Ultra-precision: ±0.005mm (0.0002 inches – this is where the pros play)

Fun Fact: A human hair is about 0.08mm thick. So we’re talking tolerances smaller than a single hair!

Material Versatility

- Metals: Aluminum, steel, titanium, brass, copper

- Plastics: PEEK, Delrin, nylon, ABS, PVC

- Composites: Carbon fiber, fiberglass

- Exotics: Inconel, Hastelloy, tungsten

Pro Tip: Not all suppliers can handle all materials. Titanium and superalloys need special equipment and expertise.

Part Complexity

- 2.5D parts: Simple shapes, pockets, holes

- 3D parts: Complex surfaces, contours

- 5-axis parts: Impossible geometries made easy

- Large parts: Up to several meters in size

Game Changer: 5-axis machining lets you make parts that were impossible just 10 years ago. One setup, perfect accuracy.

Materials Guide: Stop Guessing, Start Choosing

The Big Four: Most Common CNC Materials

Let’s get real – choosing the right material is make or break for your project. Pick wrong, and you’re looking at parts that fail, costs that skyrocket, or lead times that stretch forever.

Expert Material Selection Tips

Start with the end use: What does the part actually need to do?

Don’t over-engineer: 6061 aluminum works for 80% of applications

Consider machinability: Harder materials = longer lead times + higher costs

Check availability: Some exotic materials have 12+ week lead times

Corrosion Resistance Test Results

Salt Spray Test (500 hours)

- 316 Stainless Steel: No corrosion – 10/10

- 6061 Aluminum: Minor pitting – 7/10

- Ti-6Al-4V Titanium: No corrosion – 10/10

- Brass: Moderate tarnishing – 6/10

Test data from independent lab, results may vary in real-world conditions

Temperature Resistance

Continuous Use Temperature Limits

- Aluminum 6061: 150°C (302°F)

- Stainless Steel 304: 870°C (1600°F)

- Titanium: 480°C (900°F)

- PEEK: 260°C (500°F)

Pro Tip: For high-temperature applications, consider Inconel or Hastelloy – but be ready for sticker shock!

True Cost Comparison: It’s Not Just Material Price

Here’s the dirty secret most suppliers won’t tell you: the material price is just the beginning. You need to factor in machining time, tool wear, and finishing costs too.

The Bottom Line

Even though stainless steel only costs 1.5x more than aluminum, the total cost is 1.8x because it takes longer to machine and wears out tools faster. Always ask for total part cost, not just material price!

Machining Processes: What’s Best for Your Part?

3-Axis vs 4-Axis vs 5-Axis: The Real Differences

Let’s clear up the confusion about CNC machine axes. This isn’t just tech jargon – it directly affects your part quality, lead time, and cost.

3-Axis Machining

- Moves in X, Y, Z directions only

- Best for simple, flat parts

- Cheapest option

- Limited to 2.5D geometries

Good for: Brackets, plates, simple housings

Cost: $40-60 per hour

4-Axis Machining

- 3 linear axes + 1 rotational axis

- Can machine cylindrical parts

- Better for complex parts than 3-axis

- Still limited in some geometries

Good for: Gears, shafts, cylindrical components

Cost: $70-100 per hour

5-Axis Machining

- 3 linear axes + 2 rotational axes

- Complex geometries in one setup

- Best accuracy and surface finish

- Most versatile option

Good for: Aerospace parts, medical implants, complex components

Cost: $120-200 per hour

Game Changer: Even though hourly rate is higher, total cost is often lower for complex parts because you eliminate multiple setups!

Why 5-Axis is Worth the Investment

- One setup, perfect accuracy: No more alignment errors from multiple setups

- Complex geometries made easy: Parts that were impossible with 3-axis

- Better surface finish: Continuous tool paths eliminate visible seams

- Faster lead times: Complete parts in days instead of weeks

Real Example: A turbine blade that took 5 setups and 10 hours on 3-axis machines can be done in 1 setup and 3 hours on a 5-axis machine.

Other Key Processes

CNC Turning

- For cylindrical parts (bolts, shafts, fittings)

- Workpiece spins while tool is stationary

- Can create threads, tapers, and grooves

- Often combined with milling for complex parts

CNC Milling

- For flat parts and complex 3D shapes

- Rotating cutting tool removes material

- Can create pockets, holes, and contours

- Most common CNC process

Surface Finishing

- Anodizing: For aluminum parts (protects and colors)

- Electropolishing: For stainless steel (improves corrosion resistance)

- Passivation: For medical parts (removes free iron)

- Powder coating: For durable, colorful finishes

Quality Standards: Don’t Settle for Less

Key Certifications You Should Demand

Certifications aren’t just fancy logos – they’re proof that a supplier follows strict quality processes. Here’s what you need to look for:

ISO 9001:2015

The gold standard for quality management systems. Requires:

- Documented processes

- Continuous improvement

- Customer focus

- Regular audits

Every serious supplier should have this

AS9100D

Aerospace-specific certification. Additional requirements:

- Traceability requirements

- Risk management

- Configuration management

- Counterfeit prevention

Required for aerospace parts

ISO 13485:2016

Medical device quality standard. Key features:

- Design controls

- Risk management

- Cleanroom requirements

- Regulatory compliance

Required for medical implants and devices

IATF 16949:2016

Automotive quality management. Includes:

- Product safety focus

- Continuous improvement

- Supply chain management

- Problem solving methodologies

Preferred for automotive suppliers

Quality Control Equipment

- CMM (Coordinate Measuring Machine): For precise dimensional measurement

- Vision Inspection Systems: For visual inspection and 2D measurements

- Hardness Testers: To verify material hardness

- Surface Roughness Testers: To measure surface finish quality

Pro Tip: Ask to see photos of their quality control lab. If they can’t show you, that’s a red flag!

Inspection Processes

First Article Inspection (FAI)

Every new part gets a complete inspection before production starts. This catches issues early and ensures the process is correct.

In-Process Inspection

Random inspections during production to ensure consistency. Typically 10-20% of parts are checked.

Final Inspection

100% of parts are inspected before shipment. Includes dimensional checks, visual inspection, and functional testing if required.

Quality Guarantee: Look for suppliers that offer a quality guarantee – if parts don’t meet specs, they should remake them for free.

Statistical Process Control (SPC)

The best suppliers use SPC to monitor and control their processes. This isn’t just for big companies – any serious supplier should have these capabilities:

Process Capability Analysis

- Cp and Cpk values for critical dimensions

- Process capability > 1.33 is considered capable

- Continuous monitoring of key parameters

Control Charts

- X-bar and R charts for variable data

- P charts for attribute data

- Early detection of process drift

Root Cause Analysis

- 8D problem solving methodology

- Corrective and preventive actions

- Continuous improvement culture

What This Means for You

Suppliers with strong SPC processes deliver consistent quality, have fewer defects, and can quickly identify and fix issues before they affect your order.

How to Choose the Right CNC Supplier

The 7-Point Supplier Evaluation Checklist

Stop guessing and start evaluating suppliers systematically. Use this checklist to separate the pros from the pretenders:

Scoring Guidelines

Use this scale to evaluate each supplier:

9-10: Exceptional – exceeds all requirements

7-8: Good – meets all requirements

5-6: Acceptable – meets basic requirements

<5: Poor – does not meet requirements

China Supplier Advantages

- Cost savings: 40-60% lower than Western suppliers

- Production capacity: Large factories with many machines

- Technical expertise: Many suppliers have 20+ years experience

- Material availability: Access to wide range of materials

- Vertical integration: Often have in-house finishing and assembly

Real Data: Chinese CNC machining rates average $40-60 per hour vs. $100-150 per hour in North America.

Local Supplier Advantages

- Proximity: Easier to visit factory and inspect parts

- Communication: No language barriers or time zone issues

- Cultural understanding: Better understanding of local market needs

- Intellectual property: Perceived lower IP risk

- Shipping: Faster delivery and lower shipping costs

The Truth: IP protection in China has improved dramatically. Many Chinese suppliers now have strict confidentiality agreements.

10 Critical Questions to Ask

Don’t be shy – ask these tough questions to separate the good suppliers from the bad:

Technical Questions

- What’s your minimum tolerance capability?

- What materials do you specialize in?

- What equipment do you have?

- Can you handle our part complexity?

Quality Questions

- What certifications do you have?

- What inspection equipment do you use?

- What’s your quality guarantee?

- Can you provide quality records?

Business Questions

- What’s your typical lead time?

- Can you provide customer references?

Red Flags to Watch For

Vague answers: If they can’t give specific details

Refusal to provide references: A big warning sign

No quality certifications: Shows they don’t take quality seriously

Unrealistic lead times: If it sounds too good to be true, it probably is

Why Xiamen Goldcattle Stands Out

After evaluating hundreds of CNC suppliers, Xiamen Goldcattle consistently ranks at the top. Here’s why they’re a cut above the rest:

26 Years of Precision Experience

- Founded in 2000 – one of China’s oldest precision machining companies

- Served over 5,000 customers worldwide

- Deep expertise in aerospace, medical, automotive, and industrial sectors

- Continuous investment in training and technology

±0.005mm Precision Capability

- Ultra-precision machining – 5x more precise than standard

- State-of-the-art 5-axis machines from Germany and Japan

- Advanced CMM inspection with 0.001mm accuracy

- Process capability Cpk > 1.67 for critical dimensions

One-Stop Manufacturing Solution

- CNC machining (3-axis to 5-axis)

- CNC turning with live tooling

- Injection molding (20-500 tons)

- Sheet metal stamping

- 3D printing (SLA, SLS, FDM)

- Complete surface finishing

Quality Certifications

- ISO 9001:2015 – Quality management

- AS9100D – Aerospace quality

- ISO 13485:2016 – Medical devices

- IATF 16949:2016 – Automotive quality

- RoHS and REACH compliance

The Goldcattle Difference

What really sets Xiamen Goldcattle apart is their commitment to customer success. They don’t just make parts – they become your manufacturing partner, helping you optimize designs, reduce costs, and improve quality.

Real-World Success Stories

Case Study 1: Aerospace Component – 50% Cost Reduction

The Challenge

- Complex aluminum structural component for aircraft

- Required ±0.01mm tolerance on critical dimensions

- Previous supplier in US charging $450 per part

- Lead time: 14 days

- Quality issues: 8% scrap rate

Goldcattle’s Solution

- Redesigned for 5-axis machining (single setup)

- Optimized toolpaths using advanced CAM software

- Implemented process improvements based on 26 years experience

- Provided DFM recommendations to reduce complexity

The Results

- New cost: $225 per part

- New lead time: 4.7 days

- Improved quality: 98.8% first-pass yield

- Better surface finish: Ra 1.6µm vs. 3.2µm previously

- Annual savings: $225,000 on 1,000-piece order

Case Study 2: Medical Implant

Challenge:

Custom titanium knee implant with complex geometry and strict biocompatibility requirements. The part had 12 critical dimensions with ±0.005mm tolerance.

Solution:

- 5-axis machining for complex surfaces

- Electropolishing for biocompatibility

- Advanced quality inspection with CMM

- Complete traceability documentation

Results:

- Perfect fit – 100% patient satisfaction

- 100% biocompatibility – passed all tests

- 30% faster production than traditional methods

- 25% cost reduction compared to European supplier

Case Study 3: Automotive Component

Challenge:

High-volume production of electric vehicle battery components. Needed 10,000 parts per month with tight tolerances and consistent quality.

Solution:

- High-speed 3-axis machining with automation

- Statistical process control (SPC) monitoring

- Just-in-time delivery system

- Cost optimization through design improvements

Results:

- 10,000 parts per day production capacity

- ±0.01mm tolerance consistently achieved

- 99.9% quality rate

- 40% cost reduction compared to original supplier

Key Lessons from These Success Stories

Experience Matters

Goldcattle’s 26 years of experience allowed them to quickly identify and solve problems that would stump newer suppliers.

Technology Investment Pays Off

Their state-of-the-art 5-axis machines and inspection equipment enabled precision and efficiency that competitors couldn’t match.

Design Collaboration is Key

By working with customers to optimize designs for manufacturing, Goldcattle delivered better quality at lower cost.

Quality is Non-Negotiable

Their strict quality processes and certifications ensured parts met or exceeded customer expectations every time.

Ready to Find Your Perfect CNC Partner?

Choosing the right CNC supplier is one of the most important decisions you’ll make for your manufacturing business. The wrong choice can cost you time, money, and customers. The right choice can become a competitive advantage.

Key Takeaways

- Don’t choose based on price alone – consider quality and capability

- Look for suppliers with relevant certifications and experience

- Visit the factory or ask for a virtual tour

- Start with a small project to test the relationship

- Consider China suppliers for significant cost savings

Why Consider Xiamen Goldcattle?

With 26 years of experience, ±0.005mm precision, 5-axis capabilities, and a complete range of manufacturing services, Xiamen Goldcattle offers the perfect combination of quality, capability, and value. They’ve proven themselves with hundreds of satisfied customers worldwide.

Remember: Your supplier is an extension of your business. Choose wisely, and they’ll help you succeed. Choose poorly, and they’ll hold you back.

Frequently Asked Questions

How do I know if a Chinese supplier is reliable?

Look for established companies with 10+ years experience, international certifications, and customer references. Ask for a virtual factory tour and start with a small trial order. Companies like Xiamen Goldcattle with 26 years of experience and multiple certifications are a safe bet.

What’s the typical lead time for CNC parts?

Simple parts: 3-5 days. Complex parts: 7-14 days. Large orders: 2-4 weeks. Rush orders can often be accommodated for an additional fee. Xiamen Goldcattle typically delivers 30% faster than industry averages.

How much money can I save by using a Chinese supplier?

Typically 40-60% compared to Western suppliers. The savings come from lower labor costs, economies of scale, and efficient processes. Just make sure you’re comparing apples to apples – some suppliers cut corners to offer lower prices.

What about intellectual property protection in China?

IP protection has improved dramatically in China. Most reputable suppliers offer strict confidentiality agreements and have processes to protect your designs. Xiamen Goldcattle has never had an IP issue in 26 years of business.

How do I get started with a new supplier?

Start by sending your 3D model and 2D drawings. Most suppliers will provide a free quote and DFM analysis. Once you approve the quote, they’ll create a first article for your inspection. After you approve the first article, they’ll proceed with production.

The Ultimate Guide to CNC Machining Parts Suppliers – 2026 Edition

Created with insights from industry experts and real-world manufacturing experience