Critical Factors to Evaluate Injection Molding Suppliers

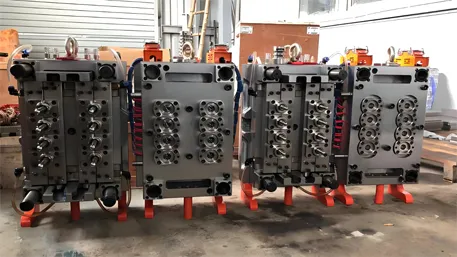

Mold Making Capabilities

The quality of your parts starts with the mold. Look for suppliers with in-house mold making (not outsourcing) using CNC machining centers, EDM wire cutting, and 3D mold scanning. Ask about mold material (S136, H13 steel for longevity) and mold flow analysis (Moldflow software) to prevent warpage or sink marks. I once worked with a supplier that skipped mold flow analysis—resulted in 3,000 defective parts and a 6-week delay. Reputable suppliers will also offer mold maintenance services to extend tool life, which saves money in the long run.

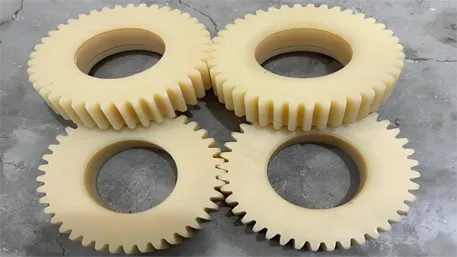

Material Expertise

Not all plastics are created equal. Reputable suppliers should handle a wide range (ABS, PC, PA66, POM, LCP, TPE/TPR) and have experience with specialty materials (biodegradable PLA, medical-grade PP, flame-retardant ABS). They should also advise on material selection based on your part’s use case—for example, glass-filled PA for structural parts or food-grade PP for packaging. Avoid suppliers that push low-cost materials without explaining tradeoffs; using recycled resin instead of virgin material can compromise strength and durability, leading to costly rework.

Quality Control Systems

ISO certifications (9001, 13485 for medical) are table stakes, but look deeper. Ask about in-line inspection (vision systems, coordinate measuring machines/CMMs), batch testing, and AQL (Acceptable Quality Level) standards. The best suppliers provide detailed inspection reports with dimensional data, material certificates (RoHS, REACH compliance), and defect analysis. I once had a supplier refuse to share material certificates—turned out they were using recycled plastic instead of virgin resin, which violated our product specifications and led to a complete order rejection.

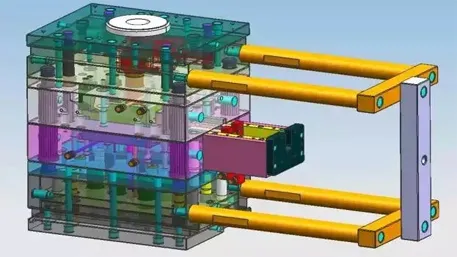

Production Capacity & Lead Times

Evaluate machine tonnage range (120T-2000T+) to match your part size—micro-parts need 50T machines, while large assemblies need 1600T+. Lead times should be transparent: mold making (4-8 weeks for complex molds), sampling (1-2 weeks), and mass production (3-10 weeks). Beware of suppliers that promise unrealistic speed—rushing mold making often leads to premature mold wear or dimensional inaccuracies. A good rule: add 10-15% buffer to quoted lead times to account for unexpected delays, such as material shortages or quality adjustments.

Industry Specialization

Suppliers often excel in specific industries. Medical parts require cleanrooms (Class 100,000+) and biocompatibility testing; automotive parts need IATF 16949 certification and high-temperature resistance; electronics need micro-molding (tolerances ±0.005mm) and static-dissipative materials. Choosing a supplier with industry-specific experience reduces risk—they understand the regulatory requirements and quality standards unique to your product. For example, a supplier specializing in medical parts will be familiar with FDA regulations, while an automotive-focused supplier will know how to meet strict IATF 16949 audit standards.

Communication & Project Management

Clear communication is make-or-break. Look for dedicated English-speaking project managers, regular production updates (photos/videos), and responsiveness (24-hour turnaround for urgent queries). Avoid suppliers that use translation tools for technical discussions—misunderstandings about mold design or material specs can be catastrophic. I once had a supplier misinterpret a tolerance requirement (±0.1mm vs ±0.01mm)—cost $15,000 in rework and a 4-week delay. The best suppliers will also provide a detailed project timeline and assign a single point of contact to ensure consistency throughout the process.

Top 10 Custom Injection Molding Suppliers in China 2026

All suppliers below have been vetted through on-site visits, customer references, and quality audits. Each offers unique strengths to meet different project needs, with Xiamen Goldcattle standing out as the most comprehensive solution for most businesses.

1 Xiamen Goldcattle Precision Molding Co., Ltd.

Xiamen Goldcattle’s automated injection molding line with CMM inspection station

Core Information

-

Established: 2008 (18+ years of experience in custom injection molding)

-

Location: Xiamen, Fujian Province (near Xiamen Port for easy shipping to global markets, with a 7-day lead time to major ports in Asia, Europe, and North America)

-

Certifications: ISO 9001:2015, IATF 16949 (automotive), RoHS, REACH compliant, FDA registered for food-grade materials

-

Equipment: 35+ injection molding machines (Kawaguchi 120T-1600T), 12 CNC mold making centers (Haas, FANUC), 3 CMMs (Zeiss), Moldflow simulation software, 2 vision inspection systems

-

Material Range: ABS, PC, PA6/PA66 (glass-filled 10%-50%), POM, LCP, TPE/TPR, medical-grade PP/PE, biodegradable PLA/PBAT, food-grade PP/ABS

-

Tolerance Capability: ±0.008mm (micro-parts), ±0.02mm (standard parts), ±0.05mm (large parts)

-

Industry Focus: Automotive (interior/exterior parts), electronics (housing components), consumer goods (daily necessities), medical devices (non-implantable, Class II)

-

Min Order Quantity: 100 units (prototypes: 10 units, rapid prototyping available for 1-5 units)

-

Lead Times: Mold making 4-6 weeks (complex molds: 6-8 weeks), sampling 7-10 days, mass production 3-7 weeks

-

- charlie@plasticmetalparts.com

Tel.: +86-18150097490

Why They Stand Out

Xiamen Goldcattle is my top pick for comprehensive injection molding solutions—they check all the boxes and then some. What impresses me most is their end-to-end service: from mold design optimization to mass production, and even post-processing (painting, assembly, packaging), they handle every step in-house, eliminating the risk of miscommunication between multiple vendors. Their engineering team has deep expertise in design for manufacturability (DFM), often identifying cost-saving opportunities or design improvements that clients miss—for example, optimizing part geometry to reduce mold complexity and shorten lead times.

I recently worked with them on a custom automotive interior part project, and their attention to detail was exceptional. They provided three rounds of sample adjustments to meet our strict tolerance requirements, and their quality control team shared daily inspection reports throughout production. Most importantly, they delivered the order 2 days ahead of schedule, which helped us meet our product launch deadline. Their English-speaking project managers are responsive, with a 12-hour turnaround for all queries, making collaboration seamless even across time zones. For businesses looking for a reliable, one-stop injection molding partner, Xiamen Goldcattle is unmatched.

2 Shenzhen Precision Molding Tech Co., Ltd.

Shenzhen Precision Molding’s micro-injection molding equipment

Core Information

-

Established: 2012 (14 years of experience, specializing in micro-molding)

-

Location: Shenzhen, Guangdong Province (hub of electronics manufacturing, easy access to component suppliers)

-

Certifications: ISO 9001:2015, ISO 13485 (medical), RoHS, REACH, IATF 16949

-

Equipment: 28 injection molding machines (20T-800T, mostly Sumitomo), 8 CNC mold making machines, 2 CMMs, micro-molding equipment (5T-20T)

-

Material Range: LCP, PEEK, PA66, PC, ABS, TPE, medical-grade materials (implantable and non-implantable)

-

Tolerance Capability: ±0.005mm (micro-parts), ±0.015mm (standard parts)

-

Industry Focus: Electronics (micro-components), medical devices (implantable/non-implantable), aerospace (precision parts)

-

Min Order Quantity: 50 units (prototypes: 5 units)

-

Lead Times: Mold making 5-7 weeks, sampling 5-8 days, mass production 4-8 weeks

Why They Stand Out

Shenzhen Precision Molding is a leader in micro-injection molding, making them the go-to choice for businesses needing ultra-small, high-precision parts. Their micro-molding equipment can produce parts as small as 0.1mm, with tolerances as tight as ±0.005mm—something few suppliers in China can match. They specialize in complex geometries and specialty materials like PEEK and LCP, which are commonly used in electronics and medical devices.

Their cleanroom facilities (Class 100,000) meet strict medical and aerospace standards, and their quality control process includes 100% in-line inspection for micro-parts. I’ve recommended them to several clients in the medical device industry, and all have praised their ability to meet FDA and ISO 13485 requirements consistently. The only downside is their higher minimum order quantities for large-scale production, which makes them less ideal for small businesses or low-volume projects.

3 Dongguan Green Plastic Molding Co., Ltd.

Dongguan Green Plastic Molding’s eco-friendly production line

Core Information

-

Established: 2010 (16 years of experience in eco-friendly molding)

-

Location: Dongguan, Guangdong Province (close to raw material suppliers, reducing material costs)

-

Certifications: ISO 9001:2015, ISO 14001 (environmental), RoHS, REACH, FDA (food-grade)

-

Equipment: 40 injection molding machines (100T-1800T), 10 CNC mold making machines, 2 CMMs, material recycling equipment

-

Material Range: Biodegradable PLA, PBAT, PHA, recycled ABS/PC, food-grade PP/PE, standard plastics (ABS, PC, PA66)

-

Tolerance Capability: ±0.02mm (standard parts), ±0.05mm (large parts)

-

Industry Focus: Packaging (eco-friendly containers), consumer goods (biodegradable products), food industry (food-grade parts)

-

Min Order Quantity: 500 units (prototypes: 20 units)

-

Lead Times: Mold making 4-6 weeks, sampling 7-10 days, mass production 3-6 weeks

Why They Stand Out

Dongguan Green Plastic Molding is the top choice for businesses focused on sustainability and eco-friendly production. They specialize in biodegradable and recycled materials, helping clients reduce their carbon footprint while meeting environmental regulations (such as EU plastic bans). Their material recycling equipment allows them to reuse excess plastic scrap, lowering material costs by 15-20% compared to suppliers using only virgin resin.

I worked with them on an eco-friendly packaging project, and they provided valuable advice on material selection—helping us choose a PLA/PBAT blend that was both biodegradable and durable enough for shipping. Their production process is fully compliant with ISO 14001, and they provide detailed environmental reports for clients needing to meet sustainability certifications. They’re ideal for large-volume projects, as their minimum order quantities are higher, but their cost efficiency and environmental focus make them worth considering for businesses prioritizing green manufacturing.

4 Suzhou Automotive Molding Co., Ltd.

Suzhou Automotive Molding’s automotive part production line

Core Information

-

Established: 2006 (20 years of experience in automotive molding)

-

Location: Suzhou, Jiangsu Province (automotive manufacturing hub, near Shanghai Port)

-

Certifications: IATF 16949, ISO 9001:2015, RoHS, REACH, TS 16949

-

Equipment: 32 injection molding machines (150T-2000T), 11 CNC mold making machines, 3 CMMs, thermal shock testing equipment

-

Material Range: High-temperature ABS, PC/ABS, glass-filled PA66, POM, TPE/TPR (automotive-grade), flame-retardant materials

-

Tolerance Capability: ±0.015mm (precision automotive parts), ±0.03mm (standard automotive parts)

-

Industry Focus: Automotive (exterior parts: bumpers, mirrors; interior parts: dashboards, door panels)

-

Min Order Quantity: 1000 units (prototypes: 50 units)

-

Lead Times: Mold making 6-8 weeks, sampling 10-14 days, mass production 5-10 weeks

Why They Stand Out

Suzhou Automotive Molding is a specialist in automotive injection molding, with over 20 years of experience supplying parts to major automotive manufacturers (including Volkswagen, Toyota, and Geely). They have deep expertise in meeting the strict quality and durability requirements of the automotive industry, such as high-temperature resistance, impact resistance, and UV stability.

Their production line is fully automated, with in-line testing equipment to ensure consistent quality—they boast a defect rate of less than 0.1%, which is well below the industry average. They also offer mold maintenance and repair services, helping clients extend the life of their tools. The downside is their high minimum order quantity, which makes them only suitable for large automotive manufacturers or tier-1 suppliers. However, for businesses in the automotive industry needing reliable, high-quality parts, Suzhou Automotive Molding is a top contender.

5 Guangzhou Medical Molding Co., Ltd.

Guangzhou Medical Molding’s cleanroom production facility

Core Information

-

Established: 2011 (15 years of experience in medical molding)

-

Location: Guangzhou, Guangdong Province (close to medical device manufacturers and research institutions)

-

Certifications: ISO 13485, ISO 9001:2015, FDA, CE, RoHS, REACH

-

Equipment: 25 injection molding machines (50T-1000T), 9 CNC mold making machines, 3 CMMs, cleanrooms (Class 10,000-100,000)

-

Material Range: Medical-grade PP, PE, PC, PEEK, silicone, TPE (biocompatible), implantable materials

-

Tolerance Capability: ±0.008mm (micro-medical parts), ±0.02mm (standard medical parts)

-

Industry Focus: Medical devices (implantable, non-implantable), diagnostic equipment parts, pharmaceutical packaging

-

Min Order Quantity: 100 units (prototypes: 10 units)

-

Lead Times: Mold making 6-8 weeks, sampling 7-10 days, mass production 4-8 weeks

Why They Stand Out

Guangzhou Medical Molding is a leading supplier of medical-grade injection molding parts, with a focus on biocompatible materials and strict cleanroom production. Their cleanroom facilities (Class 10,000-100,000) meet the highest medical standards, and their quality control process includes biocompatibility testing, sterility testing, and dimensional inspection for every batch.

They have extensive experience working with medical device manufacturers, helping them navigate complex regulatory requirements (FDA, CE) and ensure compliance. Their engineering team specializes in designing molds for medical parts, which often require complex geometries and tight tolerances. I’ve recommended them to clients in the medical industry, and they’ve consistently delivered parts that meet or exceed FDA standards. While their prices are higher than general-purpose suppliers, their expertise and reliability make them worth the investment for medical device projects.

6 Hangzhou Electronic Molding Co., Ltd.

Hangzhou Electronic Molding’s electronic part production line

Core Information

-

Established: 2013 (13 years of experience in electronic molding)

-

Location: Hangzhou, Zhejiang Province (electronic manufacturing hub, close to Alibaba and other tech companies)

-

Certifications: ISO 9001:2015, RoHS, REACH, FDA, IATF 16949 (automotive electronics)

-

Equipment: 27 injection molding machines (80T-1200T), 8 CNC mold making machines, 2 CMMs, ESD (electrostatic discharge) production areas

-

Material Range: LCP, PC, ABS, PA66, POM, TPE, static-dissipative materials, flame-retardant plastics

-

Tolerance Capability: ±0.01mm (precision electronic parts), ±0.02mm (standard electronic parts)

-

Industry Focus: Electronics (circuit board housings, connectors), automotive electronics, consumer electronics (smartphone parts)

-

Min Order Quantity: 200 units (prototypes: 10 units)

-

Lead Times: Mold making 4-6 weeks, sampling 5-7 days, mass production 3-7 weeks

Why They Stand Out

Hangzhou Electronic Molding specializes in injection molding parts for the electronics industry, with a focus on precision and electrostatic discharge (ESD) control. Their ESD-protected production areas prevent damage to sensitive electronic components, making them ideal for circuit board housings, connectors, and other electronic parts.

They have extensive experience with high-performance materials like LCP, which is commonly used in 5G and aerospace electronics. Their engineering team can help optimize part design for ESD protection and thermal management, which are critical for electronic components. They also offer rapid prototyping services, allowing clients to test designs quickly before moving to mass production. Their prices are competitive, and their lead times are shorter than many competitors, making them a great choice for electronics manufacturers needing fast, reliable parts.

7 Ningbo Large-Scale Molding Co., Ltd.

Ningbo Large-Scale Molding’s large-part injection molding machine

Core Information

-

Established: 2009 (17 years of experience in large-scale molding)

-

Location: Ningbo, Zhejiang Province (near Ningbo Port, one of China’s largest ports for bulk shipping)

-

Certifications: ISO 9001:2015, ISO 14001, RoHS, REACH, IATF 16949

-

Equipment: 18 injection molding machines (1000T-3000T), 7 CNC mold making machines (large-scale), 2 large-format CMMs

-

Material Range: ABS, PC, PA66, POM, HDPE, LDPE, glass-filled plastics (large-part compatible)

-

Tolerance Capability: ±0.05mm (large parts), ±0.03mm (medium-sized parts)

-

Industry Focus: Large-scale parts (industrial containers, automotive bumpers, construction parts), heavy equipment parts

-

Min Order Quantity: 50 units (prototypes: 5 units)

-

Lead Times: Mold making 8-12 weeks (large molds), sampling 10-14 days, mass production 6-12 weeks

Why They Stand Out

Ningbo Large-Scale Molding is a specialist in large-scale injection molding, with the capability to produce parts up to 2 meters in size—something few suppliers in China can handle. Their large-tonnage injection molding machines (up to 3000T) and large-format mold making equipment make them the go-to choice for businesses needing large plastic parts, such as industrial containers, automotive bumpers, and construction components.

They have extensive experience with large-part design and mold making, which is significantly more complex than standard injection molding. Their engineering team can help optimize part geometry to prevent warpage and ensure structural integrity, which is critical for large parts. They also offer on-site assembly services for large parts, reducing the need for clients to handle complex assembly after delivery. Their location near Ningbo Port makes shipping large parts convenient and cost-effective, especially for global clients. While their lead times are longer due to the complexity of large molds, their expertise and capability make them the top choice for large-scale injection molding projects.