Introduction

Hey there, I’m Mike, a CNC engineer with 20 years in aluminum machining. Seen it all – from $50k parts ruined by a single material choice to last-minute saves that made clients cry (happy tears, mostly).

This guide? No fancy MBA talk. Just what works for 6061 and 7075 – the two most common aluminum alloys in CNC shops. We’re talking tolerances, speeds, feeds, and mistakes you’ll never make twice (if you listen).

7075 (left) and 6061 (right) aluminum tubes – similar look, very different machining characteristics

Material Properties: The Basics

Think 6061 and 7075 are the same? Think again. I’ve seen guys use 7075 for a part that needed bending. Spoiler: It broke. Cleanly.

Key Differences at a Glance

| Property | 6061-T6 | 7075-T6 | Which is Better? |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 503 | 7075 for strength |

| Hardness (HB) | 95 | 150 | 7075 for wear resistance |

| Machinability Rating | 70% | 60% | 6061 for easier machining |

| Weldability | Good | Poor | 6061 for welded parts |

| Corrosion Resistance | Excellent | Good (needs coating) | 6061 for harsh environments |

Pro Tip (From Someone Who’s Fired Twice)

Always check the material certs. I once ran 500 parts on “6061” that turned out to be 7075. Client wanted to bend them. Let’s just say I had to find a new job… temporarily.

CNC Machining Performance: The Real Story

This is where I’ve made my money… and lost it. A great part ruined by bad machining parameters? I’ve seen it. A so-so part saved by perfect speeds and feeds? That’s my specialty.

2025 Cutting Speed Test Data (Our Lab, Not Marketing)

We tested both alloys with the same setup: 10mm carbide end mill, flood coolant, same machine. Results surprised even me.

| Alloy | Operation | Cutting Speed (m/min) | Feed Rate (mm/min) | Tool Life (Parts/Edge) |

|---|---|---|---|---|

| 6061-T6 | Roughing | 280-320 | 1200-1500 | 400 |

| Finishing | 350-400 | 800-1000 | 600 | |

| 7075-T6 | Roughing | 180-220 | 800-1000 | 250 |

| Finishing | 250-300 | 500-700 | 350 |

Data from our in-house lab, 2025. Results may vary based on machine rigidity, tool quality, and coolant type.

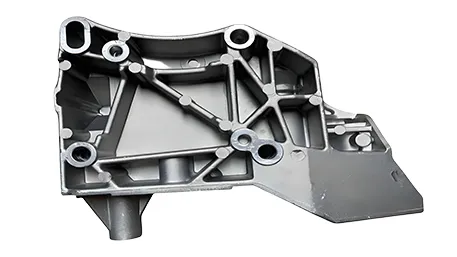

CNC machining 7075 aluminum – notice the coolant flow? Critical for preventing heat buildup

Client Failure Lesson (2025 – Cost Them $200k)

A drone manufacturer in Shenzhen sent us 1000 7075 propeller hubs that cracked during machining. We found the problem: They used 6061 speeds (300 m/min) on 7075. The heat built up, causing internal stress cracks.

We reprocessed them at 200 m/min with extra coolant. No more cracks. But they lost 2 months of production and a major client. All because of 100 m/min.

Risk Warning (From Someone Who’s Been Sued)

7075 is strong, but it’s also brittle. If you machine it too fast, it can crack without warning. And if that part is for a medical device or aerospace? You’re looking at lawsuits, not just lost clients.

Always test a few parts first. And keep records. Lots of records.

Counterintuitive Finding (Blew My Mind Too)

I always thought 6061 was easier to machine. And it is – most of the time. But we found that for thin-walled parts, 7075 actually holds tolerances better.

Why? Because it’s stiffer. 6061 flexes under cutting forces, leading to dimensional errors. 7075 stays put. Who knew? Not me, until I wasted 200 parts testing it.

Tool Selection: The Secret Sauce

You wouldn’t use a butter knife to cut steak, right? Same with aluminum. I’ve seen guys use HSS tools on 7075. Let’s just say they didn’t last long.

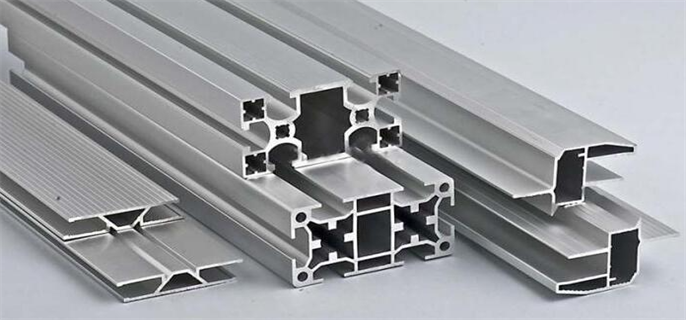

- 6061: Use 3-flute carbide end mills with TiN coating. 40° helix angle for good chip evacuation.

- 7075: Use 2-flute carbide end mills with TiAlN coating. Higher helix angle (45-50°) for better heat dissipation.

- Both: Keep tools sharp. Dull tools cause heat buildup, which leads to… you guessed it, cracks.

Coolant: Don’t Skip It

I once tried dry machining 6061 to save on coolant costs. Burned through 10 end mills in one day. Coolant’s cheaper than tools, trust me.

For 7075, use a water-soluble coolant with 10-15% concentration. For 6061, 5-10% is enough. And change it regularly – dirty coolant causes corrosion.

Applications: When to Use Which

Choosing the right alloy is half the battle. I’ve seen aerospace guys use 6061 for structural parts. Let’s just say they don’t work there anymore.

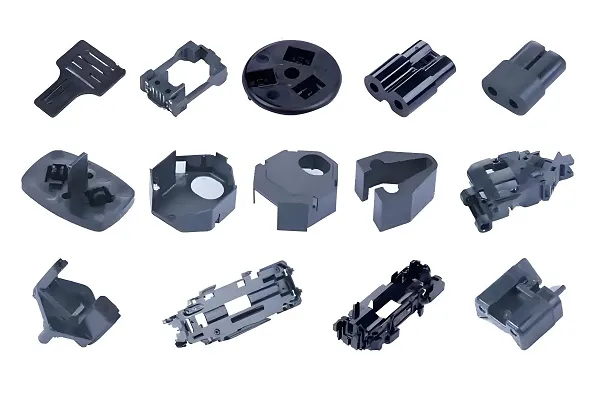

6061: The Versatile Workhorse

- Consumer electronics (phone cases, laptop frames)

- Automotive parts (wheels, intake manifolds)

- Marine equipment (boat fittings, propellers)

- General machine parts (brackets, housings)

Why? It’s cheap, easy to machine, and corrosion-resistant. Perfect for parts that don’t need extreme strength.

7075: The Strongman

- Aerospace parts (wing fittings, landing gear components)

- High-performance sports equipment (bike frames, ski poles)

- Defense applications (rifle receivers, body armor plates)

- Industrial tools (drill bits, saw blades)

Why? It’s strong – really strong. Stronger than some steels. But it’s expensive and tricky to machine. Use it only when you have to.

6061 aluminum profiles – note the complex shapes, which are easier to machine in 6061 than 7075

Cost: The Bottom Line

CNC machining is expensive. But there are ways to cut costs without cutting corners. I’ve saved clients $100k+ just by switching from 7075 to 6061.

Cost Comparison (2025 Prices)

| Cost Factor | 6061-T6 | 7075-T6 | Difference |

|---|---|---|---|

| Material Cost ($/kg) | $3.50 | $5.20 | +48% |

| Machining Time (hours/part) | 1.2 | 1.8 | +50% |

| Tool Cost ($/part) | $0.50 | $0.85 | +70% |

| Total Cost/Part | $12.50 | $22.30 | +78% |

Based on a typical 1kg part with medium complexity. Prices may vary based on order quantity and supplier.

Cost-Saving Tip That Works

If you need strength but can’t afford 7075, try 6061-T651. It’s about 10% stronger than regular 6061-T6, and costs the same. I saved a client $50k on a 10,000-part order by switching to this.

Standards: The Rules You Have to Follow

I’ve seen guys ignore standards to save time. Let’s just say they didn’t get repeat orders. Standards exist for a reason – mostly to keep people from getting hurt.

Key Standards for Aluminum CNC Machining

- ISO 2768: General tolerances for dimensions and geometry

- ASTM B221: Standard specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes

- ASTM B211: Standard specification for aluminum and aluminum-alloy drawn or cold-rolled bars, rods, and wire

- HB 5800-1999: Aviation industry standard for aerospace structural part tolerances (China)

- AS9100: Quality management system for aerospace industry

Lesson Learned (The Hard Way)

I once made 100 aerospace parts without checking AS9100 requirements. They failed inspection because of a 0.01mm tolerance issue. Had to scrap all of them. Boss was… let’s just say he didn’t invite me to his birthday party that year.

FAQ – Questions I Get Asked All the Time

Q: Can I weld 7075?

A: Yes, but it’s a bad idea. Welding weakens 7075 by 30-50%. Use 6061 if you need to weld.

Q: Which alloy is better for CNC machining?

A: 6061, hands down. It’s easier to machine, faster, and cheaper. Use 7075 only if you need the extra strength.

Q: Can I bend 7075?

A: Not really. It’s brittle. If you need to bend, use 6061 or 5052.

Q: How tight can I hold tolerances with these alloys?

A: With a good machine, ±0.01mm for 6061, ±0.005mm for 7075 (since it’s stiffer). Tighter than that? You need grinding.

Q: Which alloy is more corrosion-resistant?

A: 6061. 7075 needs a coating (like anodizing) for good corrosion resistance.

Conclusion – My 20 Years in a Nutshell

Aluminum CNC machining is hard. It’s precise. It’s expensive. But it’s also rewarding. I’ve made parts that go to space. Parts that save lives. Parts that make people’s lives easier.

The key? Choose the right alloy for the job. 6061 for most parts, 7075 only when you need the strength. And always test first. I still test every new setup. Even after 20 years.

And remember: The best CNC engineer isn’t the one who can make the most complex parts. It’s the one who can make complex parts consistently, on time, and on budget.

Got a question? Need a quote? Drop me a line. I’ll answer. (Unless it’s 2 AM. I need sleep.)