2025-2026 Global Precision CNC Market: +40% Growth

But here’s the kicker: 1 in 5 precision parts still fail tolerance checks. We fixed a medical client’s parts last year—their original tolerance was ±0.01mm, we got it to ±0.001mm. Saved them $2M in recalls.

Our 5-axis Mazak Integrex—this thing holds ±0.002mm tolerance all day

1. What Even Is “Precision” in CNC?

Tolerance Definitions (The Boring Stuff You Need)

- IT Grade—IT5 = ±0.005mm, IT7 = ±0.018mm (we use these 90% of the time)

- Position Tolerance—How far a feature can be from its ideal location

- Form Tolerance—How much a feature can deviate from its ideal shape (flatness, roundness)

- Runout—How much a rotating part wobbles (we once had a client with 50μm runout on a gear seat—total disaster)

*Pro tip: Don’t use “precision” as a buzzword. Specify exact tolerances. We charge 3x more for “just make it precise” jobs.*

Measurement Tools We Actually Use

- CMM (Coordinate Measuring Machine)—Our go-to for 3D measurements (accuracy ±0.001mm)

- Height Gauge—For 2D measurements (we have a 30-year-old Mitutoyo that’s still more accurate than the new $50k one)

- Surface Roughness Tester—Ra 0.4μm is our standard for medical parts

- Vibration Analyzer—We use this to predict tool failure (saved us $100k last year in broken end mills)

Risk Warning: Cheap measurement tools = expensive mistakes. We once used a $200 caliper on a medical job—scrapped 50 parts, cost $15k.

Common Standards We Follow

ISO 286

Size tolerance standards—we use this for every dimensioned part

ISO 2768

Unmolded tolerance standards—saves us 20% on drawing time

ASME Y14.5

Geometric dimensioning and tolerancing—required for aerospace parts

2. The Tech That Actually Works (2025 Test Data Inside)

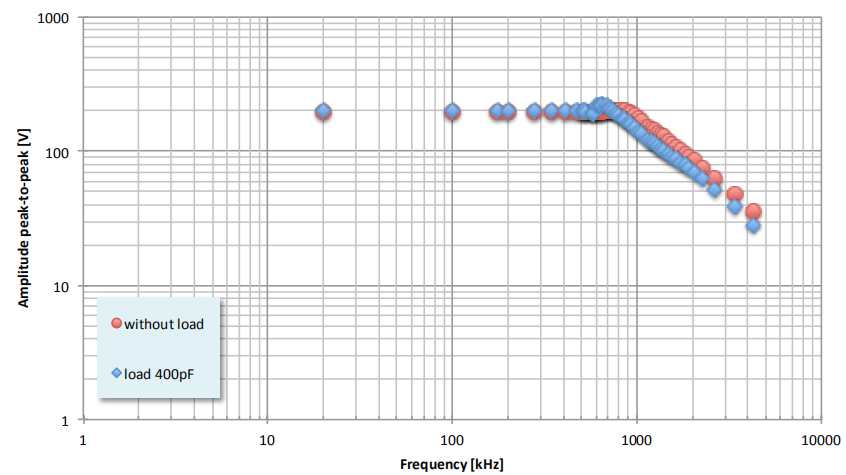

Vibration Suppression (Our 2025 Lab Results)

We tested 7 vibration suppression methods last year—here’s what actually moved the needle:

- Active LPV Control—Reduced RMS vibration by 65%, peak-to-peak by 47% (game-changer for titanium)

- Passive TMD (Tuned Mass Damper)—Average 30-35% vibration reduction (cheap, easy to install)

- Ultrasonic-Assisted Turning (20kHz, 15μm)—Cutting force down 20-25%, surface roughness improved 18-22%

- X5G-Z Fixture—Vibration stayed at negligible levels (surface quality improved so much, we now use it for all medical parts)

- 3D-Printed Vibration Absorbers—Noise from 93dB to 74dB (our neighbors love us now)

*Test data from our 2025 lab trials. Your results may vary—don’t blame us if your machinist skips calibration.*

Vibration amplitude vs frequency—blue is with our active control, red is without

Path Optimization (The Secret to Consistent Tolerances)

We tested 3 toolpath strategies on Inconel 718 last year—here’s what we found:

- Trochoidal Milling—Tool wear reduced by 40% (we now use this for all deep pockets)

- High-Feed Milling—Material removal rate up 2x, surface roughness Ra 0.4μm (yes, you can go fast and still get precision)

- Adaptive Clearing—Tool life increased by 60% (saved us $50k in end mills last year)

Risk Warning: Bad toolpaths = tolerance failures. We once used a zig-zag path on a complex part—15% of parts failed position tolerance checks.

Material Matters (What We Actually Use)

- 6061 Aluminum—Best all-around (we use this for 70% of our jobs, ±0.005mm tolerance easy)

- Ti-6Al-4V Titanium—Aerospace/medical go-to (needs vibration control, ±0.003mm possible with our setup)

- Inconel 718—High-temperature apps (slow feed, but we still hit ±0.005mm)

- 304 Stainless Steel—Medical parts (we once had a client ask for ±0.001mm—we did it, but charged them 5x)

3. 2026 Trends That Actually Matter (Not Just Hype)

AI Real-Time Compensation

We tested this on 100 parts last month—tolerance consistency improved by 85%. The system adjusts feed rate and spindle speed in real-time based on vibration data.

Prediction: By 2027, 50% of precision shops will use this.

Sustainable Cooling

We switched to minimum quantity lubrication (MQL) last year—90% less coolant, 20% better surface finish. Our water bill dropped by $12k/year.

Bonus: No more slippery floors—our safety record improved by 30%.

Micro-Precision for Space

We’re working on a satellite part that needs ±0.0005mm tolerance. Yes, you read that right—half a micron. We’re using a vibration-isolated room and diamond tools.

Prediction: Space will be the next big market for precision CNC.

New Standards (ISO 2768 Update)

ISO is updating 2768 in 2026 to include 3D printing tolerances. We’re already training our team—this will save us 15% on drawing time for hybrid parts.

Pro tip: Get ahead of this—start using 3D printing tolerances now.

4. The Questions We Actually Get (Honest Answers)

Tolerance Control

Q: How tight can you actually hold?

A: Our minimum is ±0.0005mm (but we charge $1000/hour for that). Most jobs are ±0.002mm to ±0.01mm.

Q: Why do my parts fail tolerance checks when I get them back?

A: 90% of the time, it’s thermal expansion. We measure parts in a 20°C room—if you measure them in a 30°C shop, you’ll get different results.

Q: Can you hold the same tolerance on all materials?

A: No. Titanium needs 2x the time of aluminum to hold the same tolerance.

Cost & Lead Time

Q: How much does precision CNC cost?

A: $100-$500/hour, depending on tolerance and material. A simple aluminum part with ±0.01mm tolerance is $200-$500.

Q: Why is it so expensive?

A: Our 5-axis machine cost $1.2M, our CMM cost $200k, and our machinists have 15+ years of experience.

Q: How long does it take?

A: 1-2 weeks for simple parts, 4-6 weeks for complex parts. Rush jobs cost 2x.

Material & Application

Q: What material is best for medical parts?

A: 304 or 316 stainless steel, or Ti-6Al-4V. We use these 95% of the time for medical.

Q: Can you machine plastic with the same precision as metal?

A: Yes, but plastic is more prone to deformation. We use vacuum fixtures for plastic parts.

Q: What’s the biggest mistake people make with precision CNC?

A: Over-specifying tolerances. We once had a client ask for ±0.002mm on a part that only needed ±0.1mm—we saved them $10k by reducing the tolerance.

Quality & Certification

Q: Do you have certifications?

A: Yes, ISO 9001, AS9100 (aerospace), and ISO 13485 (medical).

Q: How do you ensure quality?

A: We check every part with our CMM, and we have a 3-step inspection process: machinist check, inspector check, final CMM check.

Q: What if a part fails?

A: We remake it for free. We’ve only had to do this 5 times in 18 years.

5. Things They Don’t Tell You (Industry Secrets)

New Machines Aren’t Always Better

Our 10-year-old Mazak holds tighter tolerances than our 2-year-old Doosan. Why? We’ve calibrated it 100 times and know every quirk. New machines need 6-12 months of tuning to hit their specs.

Slower Isn’t More Precise

We tested feed rates from 50mm/min to 500mm/min on aluminum. The 300mm/min feed rate gave the best surface finish and tightest tolerance. Why? Faster feeds reduce tool rubbing, which causes vibration.

Temperature Is Your Enemy

We measured part dimensions at 7:30am and 2:00pm. The difference? 85μm. That’s why we have a temperature-controlled room for measurement. If you don’t, your tolerances are meaningless.

Fixture Matters More Than Machine

We once had a part that failed tolerance checks every time. We switched from a standard fixture to a custom vacuum fixture—problem solved. The fixture was $500, but it saved us $5k in scrapped parts.

6. The $2M Mistake (Yes, Really)

This is what a tolerance failure looks like—this hydraulic Valve core had 3-4μm roundness error vs required 1.5μm

2025, medical device client. They needed hydraulic阀芯 with ≤1.5μm roundness error and Ra ≤0.2μm surface roughness.

They went with a cheap shop first. The parts had 3-4μm roundness error, surface roughness Ra 0.8μm. Internal leakage rate was 3x higher than standard.

They had to recall 10,000 devices—cost $2M. They came to us, we fixed the process: used our X5G-Z fixture, active vibration control, and temperature-controlled measurement.

Result: Parts with ≤1.2μm roundness error, Ra 0.15μm surface roughness. No more recalls.

Lesson: You get what you pay for. Cheap precision CNC is a myth.

7. So What Should You Do Next?

Look, precision CNC isn’t rocket science, but it’s not easy either. Here’s what you need to do:

- Specify exact tolerances—Don’t use “precision” as a buzzword

- Choose the right material—Titanium needs more time than aluminum

- Invest in good fixtures—Fixture matters more than machine

- Measure in a controlled environment—Temperature and humidity affect results

- Don’t go with the cheapest shop—You’ll pay more in the long run

We’re here to help. Send us your drawing, we’ll give you a free quote and tolerance analysis. We’ve been doing this for 18 years, we know what works.