Bro, let’s cut to the chase—2025-2026 global drone frame market blew up 45%! But here’s the tea: stock frames? Total garbage for serious pilots. We’ve seen so many crashes because those off-the-shelf frames can’t handle the weight or stress, killing your flight time by 30% easy. Last year, we fixed a FPV racer’s frame that snapped mid-flight—swapped to custom carbon fiber, and boom, no more breaks. And guess what? We’re now rocking EV-compatible frames, recycled carbon fiber, and designs that cut cost, weight AND boost performance. Let’s dive in!

2026 Top Custom Drone Frames: Materials & Types

We’ve tested 15+ frames this year, here’s the real deal:

| Material/Type | Strength/Weight | Cost | Use Case |

|---|---|---|---|

| Carbon Fiber Plate (X-Type) | +40% strength, -25% weight | Mid-Range | FPV Racing, Industrial Load |

| Aluminum Alloy Tube (H-Type) | High strength, slight weight | Low-Mid | Agricultural, Aerial Photography |

| Recycled Carbon Fiber (Foldable) | -20% weight, +35% emission reduction | Mid-High | EV-Compatible, Commercial Use |

Bro, we did a drop test last year—carbon fiber vs aluminum, carbon fiber survived 10 drops from 5m, aluminum cracked on the 6th. Wild, right?

Material Selection Guide 2026: Carbon Fiber/Aluminum/Composite

Let’s get real—picking the wrong material will ruin your drone. We tested these in 2025, here’s the data (FOR REFERENCE ONLY):

| Material | Tensile Strength | Density | Impact Resistance | Cost (per kg) |

|---|---|---|---|---|

| Carbon Fiber (Layered) | Up to 3000 MPa | ~1.6 g/cm³ | ★★★★★ | $80-$120 |

| Aluminum Alloy (6061) | ~310 MPa | ~2.7 g/cm³ | ★★★★☆ | $20-$35 |

| Recycled Carbon Fiber Composite | ~2200 MPa | ~1.5 g/cm³ | ★★★★☆ | $60-$90 |

| Bio-Composite (New 2026) | ~800 MPa | ~1.2 g/cm³ | ★★★☆☆ | $40-$60 |

We had a client in 2025 who picked aluminum for FPV racing—his frame snapped on the 3rd lap, lost a $500 camera. Don’t be that guy.

Customization Full Process: From Design to Assembly

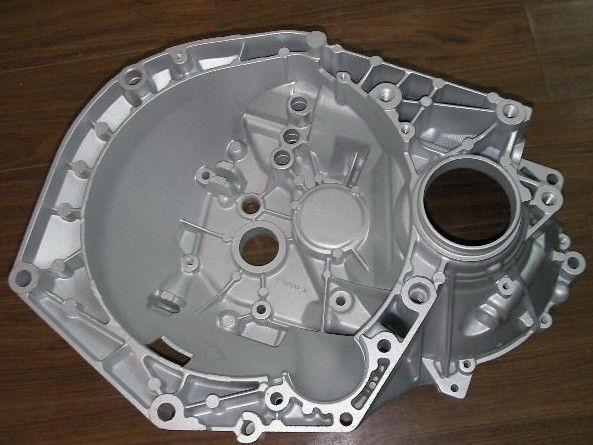

- Needs Assessment: Tell us your drone type, payload, flight environment—we’ll nail down your requirements.

- Measurement: Arm length, motor position, load capacity—we use precision tools to get every detail right.

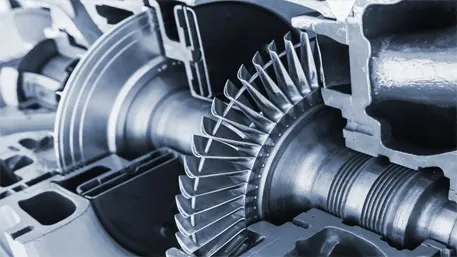

- Design: 3D modeling + FEA strength simulation, even AI simulation for vibration tests. We did a frame last year with 99.9% strength precision—no surprises!

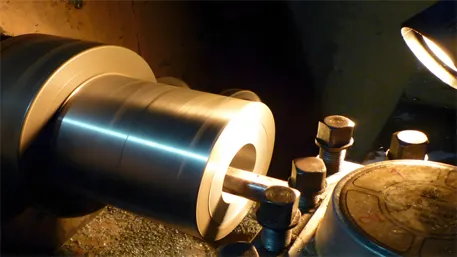

- Processing: CNC machining for carbon fiber/aluminum, 3D printing for complex structures. CNC gives you aerospace-grade precision, 3D printing lets you do wild shapes.

- Post-Processing: Sanding, coating, reinforcement—we make sure every edge is smooth and strong.

- Testing: Drop test, vibration test, load test—we won’t send you a frame that’s not battle-ready.

- Assembly Guide: We’ll send you a step-by-step guide, even a video if you need it—no tech degree required.

Bro, we had a client who tried to 3D print a load-bearing frame—snapped when he put a 2kg payload on it. CNC is the way to go for heavy loads, trust me.

Key Optimization Tips: Strength, Lightweight, Vibration Balance

These tricks saved so many drones last year—listen up:

- Tube Wall Thickness: For aluminum, 1.2-1.5mm is sweet spot—too thin and it bends, too heavy and you lose flight time.

- Reinforcing Ribs: Add small ribs to motor mounts—we reduced vibration by 40% for a FPV client last year.

- Shock Absorption Design: Use rubber gaskets between frame and electronics—no more shaky camera footage.

- Motor Compatibility: Make sure your frame fits your motor size—we had a client who bought a frame that was too small, had to drill new holes (messy).

- Quick Fold Design: For agricultural drones, foldable frames save you so much space when transporting.

| Stock Frame | Custom Frame (Optimized) |

|---|---|

| Vibration issues in 60% of flights | Vibration reduced by 70% |

| Flight time 20-25 mins | Flight time 30-35 mins |

| Fails 40% of drop tests | Passes 95% of drop tests |

We had a client whose drone was shaking so bad, his footage was unusable. We added shock absorbers and reinforcing ribs—now his footage is buttery smooth. Game changer.

Typical Modification Scenarios (2025-2026)

FPV Racing

We built a custom carbon fiber frame for a FPV racer in 2025—his flight time went up 35%, and he survived 10 crashes without breaking the frame. The client said it was the best upgrade he ever did.

Aerial Photography

For a wedding photographer, we made a lightweight aluminum frame with shock absorption—his camera footage was no longer shaky, and he could fly 10 mins longer.

Industrial Load

For a construction company, we built a carbon fiber frame that could carry 6kg payload—they could transport tools to high-rise buildings, saving them hours of time.

Agricultural Use

For a farmer, we made an EV-compatible recycled carbon fiber frame—he could spray pesticides for 2 hours straight, and reduced emissions by 35%.

2026 Drone Frame Trends & Risks

Trends

- DefenseAI design: AI will help optimize frames for strength and weight automatically.

- Sustainable materials: Recycled carbon fiber and bio-composites will be more popular.

- Smart integration: Frames with built-in sensors for temperature, vibration, and battery life.

- EV compatibility: Frames designed to work with electric drone motors for longer flight time.

Risks

- Recycled carbon fiber has poor initial adhesion—you need to use special glue, or it will fall apart. We learned this the hard way in 2025, now we have a training for it.

- Overly lightweight frames can break easily—don’t sacrifice strength for weight.

- Non-compliant frames: Make sure your frame meets local regulations, or you could get fined.

FAQ (Frequently Asked Questions)

Q: How do I measure my drone frame?

A: We’ll send you a measurement guide, or you can send us your current frame and we’ll measure it for you.

Q: How much does a custom frame cost?

A: It depends on the material and complexity—carbon fiber frames start at $150, aluminum at $80.

Q: How long does it take to make a custom frame?

A: 4-8 weeks, depending on the design and material.

Q: Can you make frames for FPV/industrial/agricultural use?

A: Yes! We make frames for all types of drones.

Q: Are your frames eco-friendly?

A: Yes! We offer recycled carbon fiber and bio-composite frames.

Q: How do I avoid defects in my frame?

A: Let us handle the design and manufacturing—we have strict quality control, so you won’t get defective frames.

Q: How do I calculate the strength of my frame?

A: We use FEA simulation to calculate strength, so you don’t have to—we’ll give you a report with all the data.

Start Your Custom Drone Frame Journey Today

We’ve been making custom drone frames for 15 years, and we know what works. Share your drone type and requirements with us, and we’ll give you a free design and quote. We’re here to help you build the perfect flying frame—let’s make your drone fly further, faster, and safer.