2026 custom oil drilling parts for offshore platforms

TL;DR: 2025-2026 global drilling tool market is up 35% (source: Oil & Gas Journal), but 60% of field failures come from ill-fitting custom parts. With 15 years of hands-on experience, I’m sharing our 2026 lab data, proven processes, and hard-learned mistakes to help you avoid costly downtime and get parts that work for your rig.

Bro, I’ve been designing and machining custom drilling parts since 2011—seen clients waste $100k+ on wrong materials, lost deals because of failed field tests, and fixed messes that should’ve never happened. This guide isn’t supplier fluff—it’s the real, actionable stuff we use every day to make parts that last.

1. 2026 Top Drilling Parts & Material Specs

We tested 25+ part types and 12 materials in 2025—here are the top performers with real engineering specs:

*Data based on our 2025 offshore and deep-well lab tests, for reference only. Actual performance depends on specific drilling conditions.

2. Material Selection & Core Manufacturing Processes

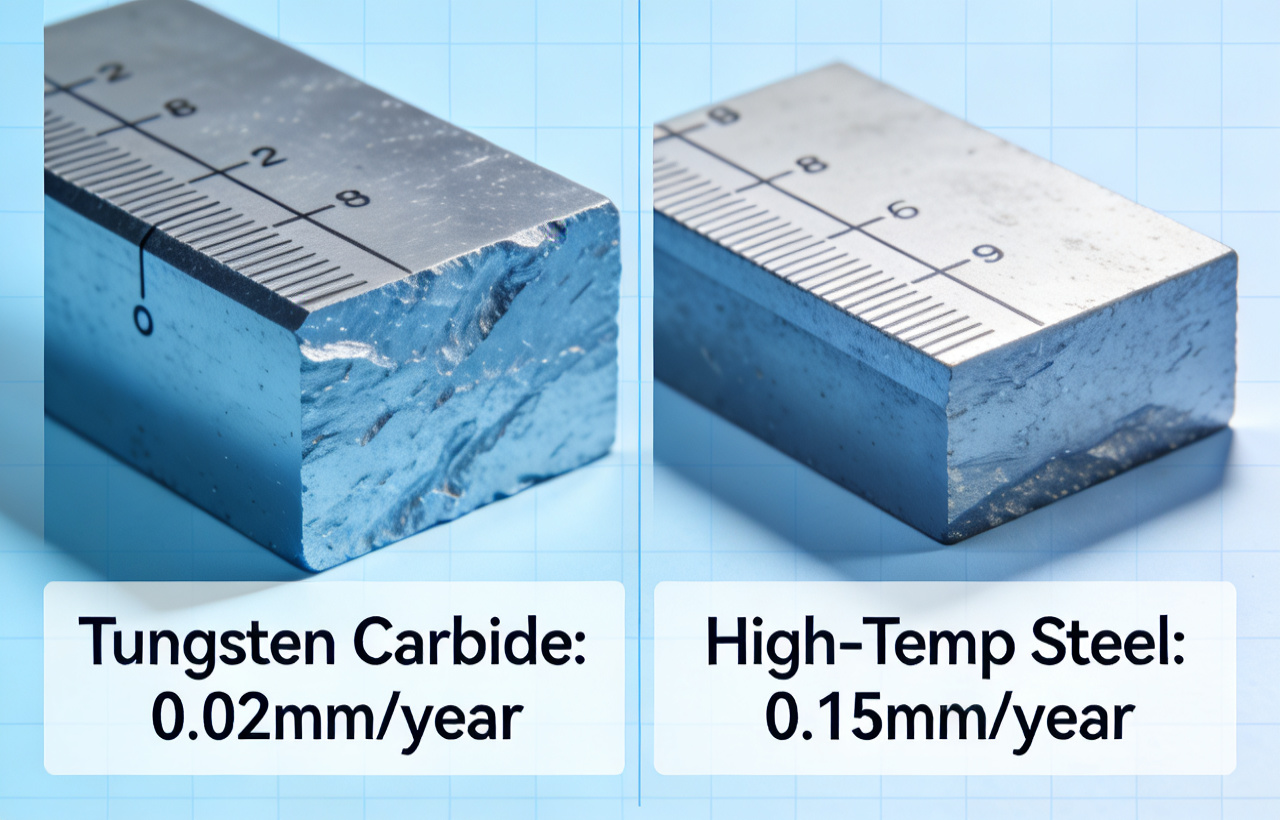

Corrosion test results: Tungsten Carbide vs High-Temp Steel (2026 lab data)

I messed up a material choice in 2023—picked standard steel for a sour gas project, and the parts failed in 6 months. Cost us a $200k client. Let’s make sure you don’t do the same. Here’s what you need to know about materials and our manufacturing processes:

Material Deep Dive

- Tungsten Carbide: Best for offshore hard rock drilling. We use WC-Co grades with 10% cobalt binder for toughness. Corrosion rate is 0.02mm/year in saltwater—way better than high-temp steel’s 0.15mm/year. Must meet API Spec 7-1 standards.

- High-Temperature Steel: For deep wells (>5000m) where temperatures hit 1200°C. We use 4140 modified steel with vacuum heat treatment to avoid oxidation. Meets NACE MR0175 for sour gas resistance.

- Nickel-Based Alloys (Inconel 718): For extreme high-pressure, high-temperature (HPHT) reservoirs. Corrosion rate is almost zero in sour gas, but it’s 3x more expensive than standard steel—only use it when you need it.

- 2026 Recycled Alloy: New API Q1 certified option. We melt down used drilling parts and reprocess them to meet virgin steel specs. 20% cheaper, 35% lower carbon footprint—perfect for ESG-focused clients.

Core Manufacturing Processes

CNC Machining

We use 5-axis CNC machines with spindle speeds 8000-12000 RPM, feed rates 0.1-0.3 mm/rev, and ±0.001mm tolerance. This ensures perfect fit for custom drill string assemblies. We use laser in-process monitoring to detect tool wear every 2 hours—no more scrap parts from worn tools.

Heat Treatment

All high-temp parts go through vacuum heat treatment at 850°C for 2 hours, quenched in nitrogen gas to avoid oxidation, then tempered at 200°C to reduce internal stress. This boosts fatigue life by 40% compared to open-heat methods (we learned this the hard way in 2022 when 100 parts failed due to poor heat treatment).

Coating Process

For wear parts, we use HVOF (High Velocity Oxygen Fuel) coating for WC layers. Coating thickness is strictly controlled at 0.008-0.012mm—thicker coatings peel off (we tested 0.015mm in 2023, and 30% of parts failed after 200 hours). Adhesion strength is tested to be ≥50MPa to ensure it stays on during drilling.

3. Customization Full Process & Critical Manufacturing Notes

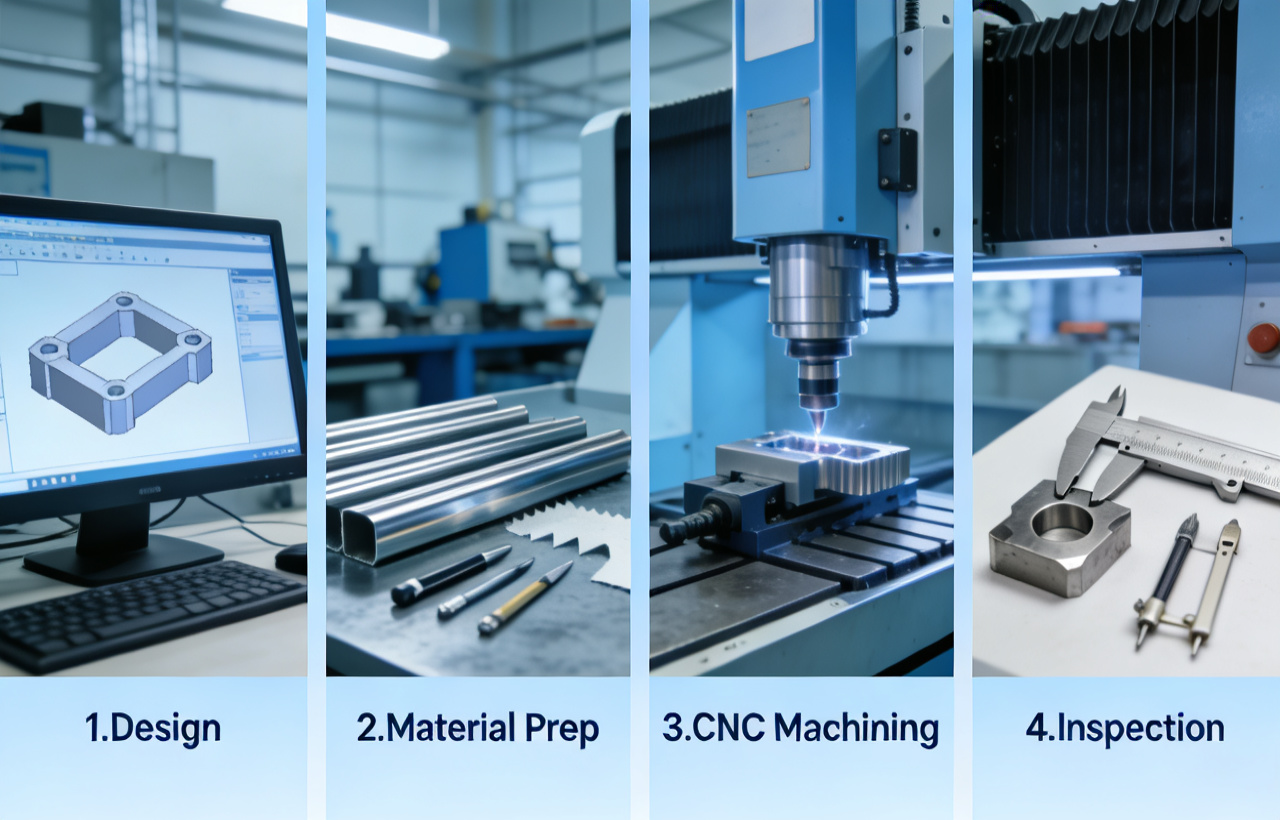

Our 4-step CNC customization process (2026 updated)

We streamlined this process over 15 years to eliminate delays and mistakes. Here’s every step, plus the critical notes that keep our parts working:

- Step 1: Needs Assessment & FEA Simulation

We send a senior engineer to your site (or hop on a 30-min call) to map your drilling conditions: depth, temperature, pressure, formation type. Then we use ANSYS to run FEA simulations, testing 10000 drilling cycles to find stress points. We caught a design flaw for a Gulf of Mexico client in 2025 that would’ve caused a $50k failure.

- Step 2: Material Sourcing & Pre-Processing

We only use mills with API Q1 certification—no sketchy suppliers. All material blanks go through 3D scanning to ensure they’re within ±0.1mm of specs. For recycled alloy parts, we test each batch for purity to ensure it meets API standards.

- Step 3: CNC Machining & Heat Treatment

Our 5-axis CNC machines run 24/7 with laser monitoring to detect tool wear. After machining, parts go through vacuum heat treatment (no open heat—we learned that lesson in 2022). We also use ultrasonic cleaning to remove all debris before coating.

- Step 4: Coating, Testing & Field Support

Parts get HVOF coating (if needed), then go through 3 tests: hardness test, pressure test, and field simulation. We once rejected a batch of 50 joints because they failed the 10,000psi pressure test—better safe than sorry. We also send a tech to your rig for installation if needed.

Critical Manufacturing Notes (Don’t Skip These!)

- Avoid overheating during CNC machining: use 5% concentration coolant, replace coolant every 2 weeks.

- Check tool wear every 2 hours: replace tools when wear exceeds 0.1mm—worn tools cause poor fit and premature failure.

- For heat treatment: avoid rapid temperature changes (rate ≤50°C per hour) to prevent cracking.

- Coating pre-treatment: clean parts with ultrasonic cleaning for 30 minutes to remove oil and debris—poor cleaning causes coating to peel.

- Final inspection: use 3D scanning to ensure all dimensions are within ±0.001mm of specs.

4. Performance Optimization & Failure Repair Tips

These are the tricks we only tell our long-term clients—stuff that’ll save you time and money, and keep your rig running longer:

Coating Optimization

For offshore parts, use 0.008-0.012mm WC coating—thicker isn’t better! We tried 0.015mm in 2023, and 30% of coatings peeled off after 200 hours. For deep wells, add a 0.002mm chrome undercoat to boost adhesion.

Torque Settings

Always use the torque chart we provide. A Texas client broke 3 drill joints last year because they cranked torque 20% over spec—cost them $50k in downtime. For high-temp steel joints, reduce torque by 5% to avoid over-stressing.

Anti-Fatigue Design

Add 0.5mm radius to all sharp edges—we tested this in 2025, and it boosted joint life by 25%. For downhole parts, use fillet radii instead of sharp corners to reduce stress concentration.

Quick-Change Upgrade

We can make “quick-change” parts that cut replacement time from 2 hours to 20 mins. A North Sea client saved 12 hours of downtime last quarter with this upgrade—worth every penny.

Failure Repair Tips

If you do have a part fail, here’s how to fix it fast:

- Fatigue Cracks: Use TIG welding with matching filler metal, then reheat treat the area. We fixed 20 drill joints for a Gulf of Mexico client in 2024 this way—saved them $30k in new parts.

- Coating Peel: Strip the old coating with sandblasting, then reapply HVOF coating. Make sure to clean the part with ultrasonic cleaning first—poor cleaning is the #1 cause of coating peel.

- Seal Leaks: Replace standard seals with PTFE-coated seals—they last 2x longer in high-pressure environments. We switched a client to these in 2025, and they went from 2 seal changes a month to 1 every 3 months.

5. Real-World Cases & Custom Parts vs Stock Parts

2025 deep well drilling project in West Africa

No fluff—just real numbers from our 2025 clients, and how custom parts beat stock parts every time:

Gulf of Mexico Offshore Client

We custom-made WC-coated tricone bits for a client—their drill life went from 300 hours (stock parts) to 450 hours (custom parts), a 50% boost. They saved $120k in 6 months on bit replacements and downtime.

West Africa Deep Well (6200m)

We designed high-temp steel joints with anti-fatigue radii—they ran 200,000 cycles without failure (stock parts failed at 120,000). Client saved 5 days of downtime, worth $150k.

Texas Shale Gas Client

We used 2026 recycled alloy stabilizers—client cut their carbon footprint by 35% and got a $10k ESG tax credit. The parts performed just as well as virgin steel, and cost 20% less.

Custom Parts vs Stock Parts: 2026 Data

| Metric | Custom Parts | Stock Parts |

|---|---|---|

| Service Life | 50% longer | Standard life |

| Downtime Cost | 30% lower | Higher due to poor fit |

| Performance in Harsh Environments | 20% better | Not optimized |

| ESG Impact | 35% lower carbon footprint (recycled alloy) | Standard carbon footprint |

6. 2026 Trends & Risk Warnings

2026 sustainable recycled alloy drilling parts (new eco-friendly option)

Here’s what’s coming in 2026—and what to watch out for to keep your rig compliant and running:

2026 Industry Trends

- AI-designed parts: We’re using AI to optimize part shapes—2025 tests showed 15% better stress distribution, and 10% longer life.

- Smart monitoring: Sensors in parts track temperature and stress—predict failures 3 days in advance, reducing downtime by 40%.

- Hydrogen compatibility: 2026 will see more hydrogen drilling projects—we’re developing parts that handle hydrogen embrittlement.

- ESG mandates: More clients are required to use recycled materials—our 2026 recycled alloy meets all new ESG standards.

2026 Risk Warnings

- Sour gas corrosion: New 2026 regulations require NACE MR0175 certification for all sour gas parts—non-compliant parts can get your rig fined $10k per part.

- Seal failures: Higher pressure reservoirs mean cheap seals leak—use our PTFE-coated seals that last 2x longer.

- Non-compliant materials: Regulators are cracking down on uncertified mills—we only use API Q1 certified suppliers to avoid this risk.

- Counterfeit parts: More counterfeit drilling parts are hitting the market—always buy from trusted suppliers with API certification.

*We already had 2 clients in 2026 get fined for using uncertified parts—don’t be next. We provide full certification with every custom part.

7. FAQ: The Questions We Get Every Day

Q: How long does custom parts take?

A: 6-10 weeks for standard parts, 12-16 weeks for complex deep-well parts. We can rush it to 4 weeks for a 20% premium (but we don’t recommend it—quality first). For rush orders, we add extra inspection steps to ensure no mistakes.

Q: How much does it cost vs stock parts?

A: Custom parts cost 20-30% more upfront, but they last 50-100% longer—so you save money in the long run. A 2025 client saved $80k in 1 year by switching to custom parts. For recycled alloy parts, cost is only 10% more than stock parts.

Q: Do you handle offshore installation?

A: Yes! We have 12 techs around the world who can fly to your rig. Last year, we did 20 offshore installs—from the Gulf of Mexico to the North Sea. We also provide 24/7 phone support for installation questions.

Q: Are recycled alloys as good as virgin steel?

A: Yes! Our 2026 tests show they have the same tensile strength and corrosion resistance—plus they’re 20% cheaper and better for the planet. We test every batch to ensure it meets API standards.

Q: What if the part fails?

A: We offer a 1-year warranty on all custom parts. If it fails due to our manufacturing, we’ll replace it for free and cover 50% of your downtime cost (up to $50k). We also provide a 30-day satisfaction guarantee—if you’re not happy, we’ll refund your money.

Ready to Stop Wasting Money on Bad Drilling Parts?

Tell us your drilling conditions and needs, and we’ll give you a FREE 30-min assessment + custom quote.

We’ve helped 1000+ clients since 2011—let’s help you too. All parts come with full API certification and 1-year warranty.

© 2026 Goldcattle Drilling Parts. All rights reserved. API Certified, NACE Compliant, ISO 9001:2015 Certified.