What Buyers Need to Know Before Choosing a Manufacturing Partner

Explore the latest CNC custom machining trends for 2025–2026, including automation, 5-axis capabilities, AI-driven platforms, and global sourcing shifts. A practical guide for procurement managers and engineers selecting reliable manufacturing partners.

Introduction

In today’s fast-moving hardware market, small-batch, high-mix, and rapid-iteration projects have become the norm rather than the exception. According to McKinsey’s latest manufacturing report, the on-demand manufacturing market is expected to grow at a 22% CAGR through 2028, driven by increasing demand for customized components across aerospace, medical, robotics, and consumer electronics industries.

For procurement managers and engineers, this shift presents both opportunities and challenges. The ability to quickly source high-quality custom CNC machining services can mean the difference between launching a product ahead of competitors or missing critical market windows. However, with so many suppliers offering CNC machining services globally, it can be difficult to identify which partners can truly deliver on their promises.

This guide will explore the key trends shaping custom CNC machining in 2025–2026, and provide practical insights to help you make more informed decisions when selecting an on-demand manufacturing partner. We’ll cover everything from the rise of digital platforms to the growing importance of 5-axis CNC machining and AI-driven workflows.

Why Custom CNC Machining Is Becoming the Preferred Option for Global Buyers

The traditional manufacturing model, which prioritized large-scale production and long lead times, is no longer sufficient for today’s dynamic market demands. Global buyers are increasingly turning to custom CNC machining services for their production needs, and for good reason.

Flexible Production for Rapid Iteration

Unlike traditional manufacturing methods that require expensive tooling and long setup times, custom CNC machining allows for quick changes to designs without significant additional costs. This is particularly valuable for startups and established companies alike that need to iterate quickly on product designs.

Lower Minimum Order Quantities (MOQs)

Custom CNC machining services typically offer much lower MOQs compared to traditional manufacturing processes. This means buyers can order as few as 1-10 parts for prototyping or 50-500 parts for small-batch production, without being forced to commit to large volumes that may go unsold.

Real-World Example

A European robotics startup needed 150 complex aluminum housing parts for their latest prototype. Traditional injection molding suppliers quoted 8-12 week lead times with $15,000 in tooling costs. By working with a custom CNC machining service, they received their parts in 10 days with no upfront tooling investment, allowing them to accelerate their product development timeline by 3 months.

Faster Time-to-Market

In today’s competitive business environment, speed is everything. Custom CNC machining services can typically provide quotes within 24-48 hours and deliver parts in 7-14 days, significantly reducing time-to-market compared to traditional manufacturing methods that can take months.

These shifts in buyer demand are being driven by three major trends that are fundamentally transforming the custom CNC machining industry. Understanding these trends is essential for any procurement manager or engineer looking to source CNC parts globally.

Three Major Trends Driving the Future of Custom CNC Machining

Digital Platforms Are Transforming How Buyers Source CNC Parts

The rise of on-demand manufacturing platforms like Xometry, Proto Labs, and Xiamen Goldcattle has revolutionized how buyers source custom CNC machining services. These digital platforms connect buyers with a global network of pre-vetted manufacturers, providing instant quotes, online material selection, and real-time order tracking.

Key Benefits for Buyers:

- Instant Quoting: Upload your CAD file and receive a quote within minutes, not days

- Global Supplier Network: Access to hundreds of manufacturers with specialized capabilities

- Transparent Pricing: No hidden fees or surprise costs

- Real-Time Tracking: Monitor your order progress from start to finish

For traditional CNC factories, these platforms present both challenges and opportunities. While they increase competition, they also provide access to a global customer base that would be difficult to reach through traditional marketing channels. Leading Chinese CNC machining services have successfully integrated with these platforms, leveraging their advanced capabilities to compete on a global stage.

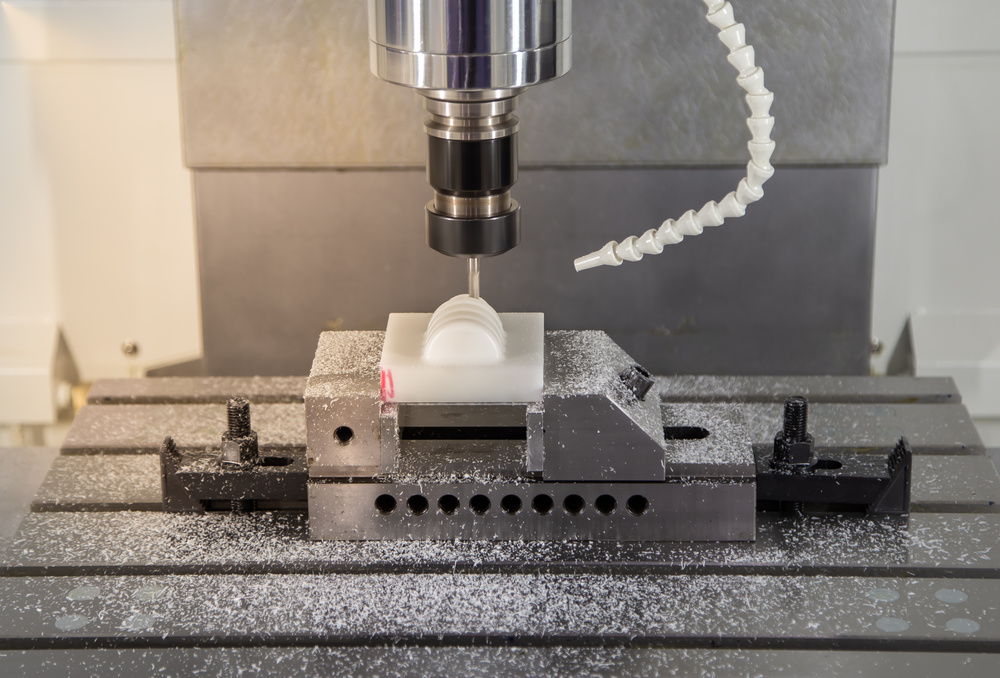

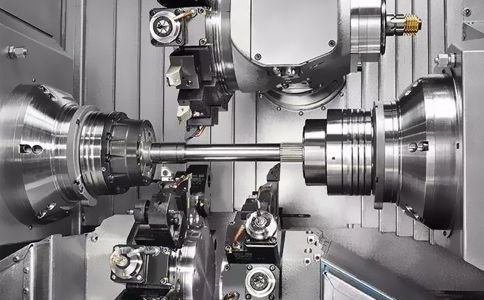

5-Axis Machining and Automation: The New Standard for High-Precision Custom Parts

5-axis CNC machining is rapidly becoming the standard for producing complex, high-precision parts across industries such as aerospace, medical devices, and robotics. Unlike traditional 3-axis machines, 5-axis machines can move the workpiece or tool along five different axes simultaneously, allowing for more complex geometries to be produced in a single setup.

Advantages of 5-Axis Machining:

- Complex Geometries: Ability to produce intricate shapes that would be impossible with 3-axis machining

- Single Setup Production: Eliminates the need for multiple setups, reducing production time and improving accuracy

- Improved Surface Finish: Better surface quality due to continuous tool contact with the workpiece

- Reduced Material Waste: More efficient material utilization compared to traditional machining methods

Alongside 5-axis machining, automation is transforming the CNC manufacturing landscape. Robotic loading systems, intelligent tool changers, and lights-out manufacturing capabilities are becoming increasingly common in modern CNC facilities.

These automation technologies offer significant benefits for buyers, including higher production consistency, reduced lead times, and improved quality control. With automated systems, manufacturers can run production 24/7 without human intervention, significantly increasing output capacity.

How AI Is Making Custom CNC Machining Faster and More Predictable

Artificial intelligence is no longer just a buzzword in the manufacturing industry—it’s becoming an essential tool for improving efficiency and quality in custom CNC machining. AI-powered systems are being integrated into every stage of the CNC workflow, from initial design analysis to final quality inspection.

AI Applications in CNC Machining:

Automated DFM Feedback

AI systems can analyze CAD files and provide instant Design for Manufacturing (DFM) feedback, identifying potential issues and suggesting design improvements to optimize machining efficiency and reduce costs.

Intelligent Toolpath Optimization

AI algorithms can optimize toolpaths to reduce machining time while maintaining or improving part quality, resulting in faster production times and lower costs.

Predictive Maintenance

AI systems can monitor machine performance in real-time, predicting potential failures before they occur and allowing for proactive maintenance that reduces downtime.

Quality Control Automation

AI-powered vision systems can inspect parts with micron-level accuracy, identifying defects that would be difficult for human inspectors to detect, ensuring consistent quality across production runs.

For buyers, the integration of AI into CNC machining means faster quote turnaround times, more accurate lead time predictions, and higher quality parts. AI is not just making CNC machining faster—it’s making it more predictable and reliable.

What These Trends Really Mean for Procurement Managers and Engineers

The Shifting Criteria for Selecting a CNC Partner

The traditional approach to selecting CNC manufacturing partners is no longer sufficient in today’s rapidly evolving market. Buyers need to shift their focus from purely cost-based decisions to a more holistic evaluation that considers technical capabilities, engineering support, and long-term partnership potential.

This shift in evaluation criteria reflects the changing nature of manufacturing relationships. Today’s buyers need partners who can provide more than just production capabilities—they need strategic allies who can help them optimize their designs, reduce costs, and accelerate time-to-market.

5 Key Capabilities Every Serious Buyer Should Look For

1. Multi-axis Machining Expertise

Look for suppliers with proven experience in 3-, 4-, and 5-axis CNC machining to ensure they can handle your most complex part geometries.

2. Broad Material Experience

A capable CNC partner should have experience working with a wide range of metals and engineering plastics, including exotic materials.

3. Rapid DFM Feedback

The ability to provide proactive Design for Manufacturing feedback within 24-48 hours can save you significant time and money in the long run.

4. Robust Quality Control

Look for ISO 9001/AS9100 certification and advanced inspection equipment to ensure consistent part quality across all production runs.

5. International Project Experience

A reliable global partner should have proven experience working with international clients, including English communication skills and adherence to global standards.

Leading custom CNC machining services have already embraced these capabilities, positioning themselves as strategic partners rather than just suppliers. When evaluating potential partners, look for companies that can demonstrate these capabilities through case studies, client testimonials, and direct technical discussions.

Why China Remains a Strategic Choice—But for Different Reasons

For many years, China was primarily known as a low-cost manufacturing destination. However, the landscape has changed significantly, and today China offers much more than just competitive pricing for custom CNC machining services.

Advanced Technical Capabilities

Many Chinese CNC manufacturers have invested heavily in state-of-the-art equipment, including 5-axis machining centers, automated production lines, and advanced quality control systems. This allows them to produce complex, high-precision parts that meet the strictest international standards.

Mature Supply Chain Ecosystem

China has a well-developed supply chain ecosystem for manufacturing, with easy access to a wide range of materials, finishes, and secondary operations. This integrated approach can significantly reduce lead times and improve overall project efficiency.

Improved IP Protection

Intellectual property protection has been a major concern for international buyers sourcing from China. However, significant improvements have been made in recent years, with many manufacturers implementing strict IP protection policies and procedures to safeguard client designs.

Strong Engineering Support

Many Chinese CNC manufacturers now employ teams of experienced engineers who can provide valuable DFM feedback, design optimization suggestions, and technical support throughout the entire production process.

Industry Insight

According to a recent survey by the Association for Manufacturing Technology, 78% of North American and European manufacturers now consider Chinese suppliers as equal in quality to domestic suppliers for custom CNC machining services, with 62% citing cost-effectiveness and technical capabilities as the primary reasons for sourcing from China.

While China is no longer the cheapest option, it remains a strategic choice for many international buyers due to its combination of advanced technical capabilities, competitive pricing, and reliable delivery performance.

A Practical Checklist for Choosing Your Next Custom CNC Partner

To help you make an informed decision when selecting a custom CNC machining partner, we’ve created a practical checklist that you can use during your evaluation process:

- Do they provide proactive DFM suggestions within 24–48 hours?

This is a critical indicator of their engineering capabilities and commitment to helping you optimize your design for manufacturability. - Can they seamlessly scale from prototype to low-medium volume production?

Look for partners who can support you throughout your product lifecycle, from initial prototyping to full production. - Do they have verified experience in your industry?

Different industries have different requirements—make sure your partner understands the specific needs and standards of your industry. - Do they offer a full range of surface finishes and secondary operations?

This can help you avoid the need to work with multiple suppliers, reducing complexity and lead times. - How fast do they respond to RFQs and design changes?

Responsive communication is essential for keeping your project on schedule. - Can they provide detailed quality reports and inspection data?

Transparent quality control processes are essential for ensuring consistent part quality. - Do they have experience working with international clients?

International experience indicates they understand the unique challenges of global sourcing. - Can they provide references from clients with similar project requirements?

Client references are one of the best ways to verify a supplier’s capabilities and reliability.

By using this checklist during your supplier evaluation process, you can significantly reduce the risk of selecting a partner who may not be able to meet your specific needs. Remember, the goal is to find a long-term partner who can grow with your business and help you achieve your manufacturing goals.

Final Thoughts: In a Rapidly Changing Market, the Right Partner Matters More Than Ever

The custom CNC machining industry is undergoing significant transformation, driven by advances in technology, changing buyer demands, and evolving global supply chains. As we look ahead to 2025–2026, it’s clear that the traditional approach to manufacturing is no longer sufficient.

Today’s procurement managers and engineers need to adapt to these changes by re-evaluating their supplier selection criteria and looking for partners who can provide more than just production capabilities. The right CNC partner should be a strategic ally who can help you optimize your designs, reduce costs, and accelerate time-to-market.

By understanding the key trends shaping the industry—including the rise of digital platforms, the mainstream adoption of 5-axis machining, and the integration of AI into manufacturing workflows—you can make more informed decisions when selecting a custom CNC machining partner.

Ready to Find Your Ideal CNC Machining Partner?

If you’re looking for a custom CNC machining partner that combines advanced capabilities with responsive international service, we’re here to help.

Remember, in today’s fast-paced manufacturing environment, the right partner can make all the difference. By choosing a supplier that embraces the latest trends and technologies, you can position your business for success in the years ahead.

Additional Resources