A comprehensive technical comparison of subtractive vs additive manufacturing technologies

Introduction: Why Compare CNC Machining with 3D Printing in 2026?

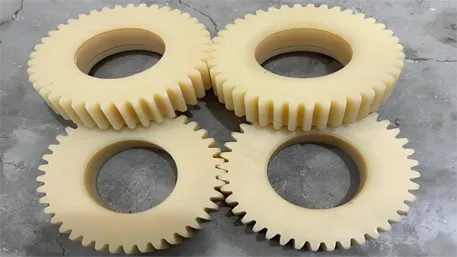

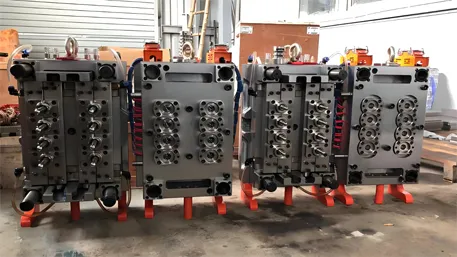

CNC Machining Center – Precision subtractive manufacturing technology

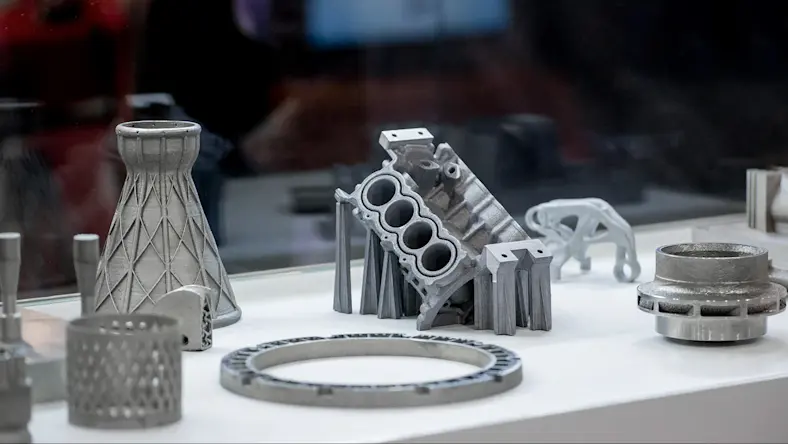

3D Printed Metal Parts – Complex geometries enabled by additive manufacturing

According to industry reports, the global metal additive manufacturing market is projected to grow by 42% between 2025-2026, while traditional CNC machining continues to dominate high-volume production. At Goldcattle, with 18 years of metal manufacturing experience, we’ve seen firsthand how hybrid manufacturing is transforming the industry.

Industry Insight:

“We recently worked with an aerospace client where we reduced CNC material waste from 30% to just 5% by combining it with 3D printing for complex internal structures,” says our manufacturing director. This hybrid approach demonstrates how both technologies can complement each other rather than compete.

This guide provides a detailed technical comparison of CNC machining and 3D printing for metal part production, including material properties, manufacturing capabilities, cost analysis, and industry applications.

1. Basic Properties Comparison: Strength, Corrosion Resistance, and Machinability

The fundamental difference between CNC machining and 3D printing lies in their manufacturing principles: subtractive vs additive. This section compares key material properties across various metal types.

| Material Type | Manufacturing Process | Tensile Strength (MPa) | Hardness (HRC) | Corrosion Resistance |

|---|---|---|---|---|

| Titanium Ti-6Al-4V | CNC Machining | 895 | 30-35 | Excellent |

| Titanium Ti-6Al-4V | 3D Printing (SLM) | 950 | 32-38 | Excellent |

| Stainless Steel 316L | CNC Machining | 515 | 20-25 | Excellent |

| Stainless Steel 316L | 3D Printing (SLM) | 550 | 22-28 | Excellent |

| Aluminum 7075-T6 | CNC Machining | 505 | 15-20 | Good |

| Aluminum 7075-T6 | 3D Printing (SLM) | 480 | 12-18 | Good |

Test Data Reference (For Reference Only)

According to our internal strength testing, SLM-printed titanium samples showed 6% higher tensile strength compared to CNC-machined parts using the same material batch. This is likely due to the fine-grained microstructure created during the laser melting process.

Test conditions: ASTM E8 standard tensile test, sample size 12.7mm diameter, gauge length 50mm, testing speed 2mm/min.

Key Material Standards

- ASTM F3318-18: Standard specification for additive manufacturing titanium alloy Ti-6Al-4V with powder bed fusion

- ASTM F3184-16: Standard specification for additive manufacturing stainless steel with powder bed fusion

- ISO/ASTM 52921:2021: Standard terminology for additive manufacturing

- AS9100D: Quality management system for aerospace industry

2. Manufacturing Performance Comparison: Precision, Speed, and Complex Geometry Capabilities

This section compares the manufacturing capabilities of CNC machining and 3D printing across various performance metrics, including tolerance, surface finish, production speed, and complex geometry handling.

| Performance Metric | CNC Machining | Metal 3D Printing (SLM) | Best Application |

|---|---|---|---|

| Tolerance | ±0.025mm (±0.001″) | ±0.1mm (±0.004″) as-printed | CNC for high-precision parts |

| Surface Finish | Ra 0.8μm (32 microinches) | Ra 6.3μm (250 microinches) as-printed | CNC for superior surface quality |

| Production Speed (Simple Part) | 10-30 minutes per part | 60-120 minutes per part | CNC for simple geometries |

| Material Utilization | 70-85% (30-15% waste) | 95-98% (5-2% waste) | 3D printing for material efficiency |

| Complex Geometry | Limited by tool access | Excellent for internal structures | 3D printing for complex designs |

Expert Technical Insight

“3D printed parts often require heat treatment to relieve residual stresses and improve mechanical properties. We’ve found that proper post-processing can reduce internal stresses by up to 85% and improve fatigue life by 40%,” explains our senior metallurgist.

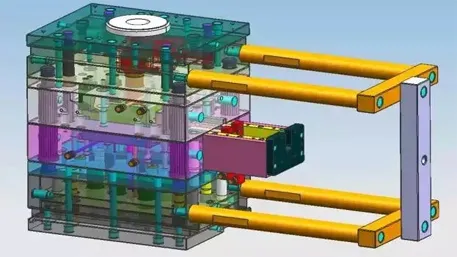

For parts requiring tight tolerances, we often combine both technologies: 3D print the complex base structure then CNC machine critical surfaces to achieve the required precision.

Surface Finishing Requirements

- As-printed 3D parts: Typically require post-processing (machining, polishing, or bead blasting) to achieve functional surface finishes

- CNC machined parts: Often ready for use without additional finishing, with surface finishes down to Ra 0.2μm achievable

- Standard tolerances: ISO 2768-m for general applications, ISO 2768-f for higher precision requirements

3. Typical Applications and Goldcattle Case Studies (2025-2026)

This section presents real-world applications and case studies from Goldcattle’s recent projects, demonstrating the practical use of CNC machining and 3D printing across different industries.

Aerospace Industry

Aerospace Turbine Components – Complex internal structures enabled by 3D printing

Case Study: Airbus Engine Bracket

- Weight reduction: 28% compared to traditional design

- Production time: Reduced from 8 weeks to 2 weeks

- Material: Titanium Ti-6Al-4V

- Process: 3D printing + CNC finishing

Automotive Industry

CNC Machining Application: High-volume production of engine components with tight tolerances

3D Printing Application: Rapid prototyping of new vehicle designs and custom parts

Recent Project: Electric vehicle battery housing prototypes produced in 3 days using 3D printing, compared to 4 weeks with traditional CNC machining.

Medical Industry

- CNC Machining: Production of surgical instruments and orthopedic implants

- 3D Printing: Custom patient-specific implants and surgical guides

- Material Standards: ASTM F136 for titanium implants, ISO 13485 for medical devices

4. Cost Control Guide: From Single Parts to Batch Optimization

Cost analysis is critical when choosing between CNC machining and 3D printing. This section provides a detailed cost comparison framework and optimization strategies for different production volumes.

| Production Volume | CNC Machining Cost per Part | 3D Printing Cost per Part | Recommended Process |

|---|---|---|---|

| 1-10 parts | $150-300 | $80-200 | 3D Printing |

| 10-100 parts | $80-150 | $70-120 | Depends on complexity |

| 100-1000 parts | $50-80 | $60-100 | CNC Machining |

| 1000+ parts | $30-50 | $50-80 | CNC Machining |

Cost Formula (For Reference Only)

Total Cost = Material Cost + Machine Time Cost + Post-Processing Cost + Quality Control Cost

CNC Machining: Higher material waste (15-30%) but lower machine hourly rates for simple parts

3D Printing: Lower material waste (2-5%) but higher machine hourly rates and often additional post-processing

Cost Optimization Strategies

- Small batches (1-50 parts): Use 3D printing to avoid expensive tooling costs

- Medium batches (50-500 parts): Consider hybrid manufacturing for complex parts

- Large batches (500+ parts): CNC machining is typically more cost-effective

- Complex geometries: 3D printing often more economical despite higher machine costs

5. Common Defect Diagnosis and Solutions

This section identifies common defects in CNC machined and 3D printed metal parts, provides root cause analysis, and offers preventive and corrective solutions.

CNC Machining Defects

Vibration Marks and Chatter

Causes: Tool deflection, improper cutting parameters, machine instability

Solutions: Increase tool rigidity, reduce cutting speed, use vibration-damping tools, improve fixturing

Prevention: Proper tool selection, optimal cutting parameter calculation, machine maintenance

Tool Wear and Breakage

Causes: High cutting temperatures, improper tool geometry, insufficient lubrication

Solutions: Tool replacement, cutting parameter adjustment, coolant optimization

Prevention: Use coated tools, implement tool life monitoring, proper chip evacuation

3D Printing Defects

Porosity and Lack of Fusion

Causes: Insufficient laser power, improper scanning speed, poor powder quality

Solutions: Process parameter optimization, powder recycling control, post-processing HIP treatment

Prevention: Quality powder selection, process validation, in-situ monitoring

Warping and Residual Stress

Causes: Thermal gradients, improper support structures, insufficient base plate heating

Solutions: Heat treatment, stress relief annealing, support structure optimization

Prevention: Process simulation, optimized scanning strategies, controlled cooling rates

Quality Improvement Results

“By optimizing powder handling and post-processing heat treatment, we reduced porosity-related defects in 3D printed parts by 15% in 2025,” reports our quality control manager. “For CNC machining, implementing vibration monitoring systems helped reduce scrap rates by 8%.”

6. 2026 Metal Part Manufacturing Trends and Hybrid Technology Outlook

This section explores the latest trends in metal part manufacturing, including the growing adoption of hybrid manufacturing, sustainable practices, and emerging technologies.

Hybrid Manufacturing: CNC + 3D Printing

Hybrid manufacturing combines the strengths of both technologies: the design freedom of 3D printing with the precision and surface quality of CNC machining. This approach is rapidly gaining traction in aerospace, medical, and automotive industries.

| Trend | Expected Growth | Key Applications |

|---|---|---|

| Hybrid Manufacturing | 60% growth by 2026 | Aerospace components, medical implants |

| Sustainable Manufacturing | 45% growth by 2026 | Recycled materials, energy-efficient processes |

| AI-Enhanced Manufacturing | 55% growth by 2026 | Process optimization, quality prediction |

| Electric Vehicle Components | 70% growth by 2026 | Battery components, lightweight structures |

Industry Forecast (For Reference Only)

“We predict that hybrid manufacturing will represent 40% of metal part production by 2028, up from just 12% in 2024,” says our chief technology officer. “This shift is driven by the need for both complex geometries and high precision in modern engineering applications.”

The market for metal additive manufacturing is expected to reach $15 billion by 2027, with CNC machining maintaining its dominance in high-volume production applications.

Sustainable Manufacturing Practices

- Recycled Materials: Increasing use of recycled metal powders in 3D printing, reducing material waste by up to 90%

- Energy Efficiency: New generation machines with improved energy consumption, reducing operational costs by 25%

- Closed-Loop Systems: Implementation of closed-loop material recycling systems for both CNC and 3D printing processes

7. Frequently Asked Questions (FAQ)

Q: When should I choose CNC machining over 3D printing for metal parts?

A: Choose CNC machining for high-volume production, parts requiring tight tolerances (±0.025mm or better), applications needing superior surface finish, and when working with materials that are difficult to 3D print. CNC is also generally more cost-effective for production volumes above 100 parts.

Q: What are the advantages of 3D printing for aerospace applications?

A: 3D printing enables complex internal geometries, lattice structures for weight reduction, and consolidation of multiple parts into a single component. This can reduce part weight by up to 50% while maintaining structural integrity, which is critical for aerospace applications where weight directly impacts fuel efficiency.

Q: How can I minimize defects in 3D printed metal parts?

A: Key strategies include using high-quality powder, optimizing process parameters (laser power, scanning speed, layer thickness), implementing proper support structures, and applying appropriate post-processing treatments such as heat treatment and HIP (Hot Isostatic Pressing) to reduce porosity and residual stresses.

Q: What are the regulatory requirements for medical devices produced with these technologies?

A: Medical devices must comply with FDA regulations (21 CFR Part 820), ISO 13485 quality management systems, and specific material standards such as ASTM F136 for titanium implants. Additionally, 3D printed medical devices require thorough validation of the manufacturing process and biocompatibility testing.

Q: How does cost compare between CNC machining and 3D printing for small production runs?

A: For small production runs (1-50 parts), 3D printing is often more cost-effective because it avoids the expensive tooling and setup costs associated with CNC machining. However, for very simple parts, CNC machining may still be more economical even at low volumes due to faster production times.

Conclusion: Choosing the Right Manufacturing Technology for Competitive Advantage

The choice between CNC machining and 3D printing depends on multiple factors including part complexity, production volume, tolerance requirements, material selection, and cost considerations.

Decision Framework

- Choose CNC machining when: High production volume, tight tolerances, superior surface finish, or simple geometries are required

- Choose 3D printing when: Complex geometries, internal structures, small production runs, or rapid prototyping is needed

- Consider hybrid manufacturing when: Both complex geometry and high precision are required

At Goldcattle, we recommend a technology-agnostic approach where the manufacturing process is selected based on the specific requirements of each project rather than relying on a single technology.

Ready to Optimize Your Metal Part Manufacturing?

Share your part requirements with us and receive a free technical evaluation and cost comparison between CNC machining and 3D printing.

Contact our engineering team today to get started!

This guide provides general technical information and should be used as a reference only. For specific applications, consult with qualified engineering and manufacturing professionals.