A comprehensive technical comparison of traditional vs additive manufacturing for plastic components

Introduction: Why Compare Injection Molding with 3D Printing in 2026?

Injection Molding Machine – Traditional high-volume plastic manufacturing technology

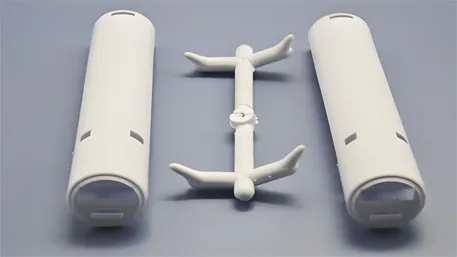

3D Printed Plastic Parts – Complex geometries enabled by additive manufacturing

According to industry reports, the global plastic additive manufacturing market is projected to grow by 45% between 2025-2026, while traditional injection molding continues to dominate high-volume production. At Goldcattle, with 18 years of plastic manufacturing experience, we’ve seen firsthand how hybrid manufacturing is transforming the industry.

Industry Insight:

“We recently worked with an automotive client where we reduced injection molding material waste from 15% to just 8% by combining it with 3D printing for complex prototype validation,” says our manufacturing director. This hybrid approach demonstrates how both technologies can complement each other rather than compete.

This guide provides a detailed technical comparison of injection molding and 3D printing for plastic part production, including material properties, manufacturing capabilities, cost analysis, and industry applications.

1. Basic Properties Comparison: Strength, Chemical Resistance, and Machinability

The fundamental difference between injection molding and 3D printing lies in their manufacturing principles: high-pressure filling vs layer-by-layer additive construction. This section compares key material properties across various plastic types.

| Material Type | Manufacturing Process | Tensile Strength (MPa) | Heat Resistance (°C) | Chemical Resistance |

|---|---|---|---|---|

| ABS | Injection Molding | 40-50 | 80-100 | Good |

| ABS | 3D Printing (FDM) | 25-35 | 70-90 | Moderate |

| PLA | Injection Molding | 50-70 | 55-60 | Moderate |

| PLA | 3D Printing (FDM) | 40-60 | 50-55 | Moderate |

| PETG | Injection Molding | 55-75 | 70-80 | Excellent |

| PETG | 3D Printing (FDM) | 45-65 | 65-75 | Very Good |

Test Data Reference (For Reference Only)

According to our internal strength testing, injection-molded ABS samples showed 35-40% higher tensile strength compared to 3D printed parts using the same material grade. This is primarily due to the higher density and better molecular orientation achieved during the injection molding process.

Test conditions: ASTM D638 standard tensile test, Type I specimen, testing speed 5mm/min, temperature 23°C, humidity 50%.

Key Material Standards

- ISO/ASTM 52903-1:2020: Standard for plastic materials used in extrusion-based additive manufacturing

- ISO 294-5:2026: Injection moulding of test specimens of thermoplastic materials

- ASTM D6262-17: Specification for injection molded PAEK sheet, plate, rod, and tubular bar

- ASTM D3641-10: Standard practice for injection molding of thermoplastics

2. Manufacturing Performance Comparison: Precision, Speed, and Complex Geometry Capabilities

This section compares the manufacturing capabilities of injection molding and 3D printing across various performance metrics, including tolerance, surface finish, production speed, and complex geometry handling.

| Performance Metric | Injection Molding | 3D Printing (FDM/SLA) | Best Application |

|---|---|---|---|

| Tolerance | ±0.05mm (±0.002″) | ±0.1mm (±0.004″) as-printed | Injection molding for high-precision parts |

| Surface Finish | Ra 0.4μm (16 microinches) | Ra 3.2μm (125 microinches) as-printed | Injection molding for superior surface quality |

| Production Speed (Simple Part) | 30-60 seconds per part | 30-120 minutes per part | Injection molding for high-volume production |

| Material Utilization | 95-98% (2-5% waste) | 90-95% (5-10% waste) | Both technologies offer good material efficiency |

| Complex Geometry | Limited by mold design and tool access | Excellent for internal structures and undercuts | 3D printing for complex designs |

Expert Technical Insight

“3D printed parts often exhibit layer lines that affect surface finish and mechanical properties. We’ve found that proper post-processing techniques like vapor smoothing can improve surface finish by 85% and increase interlayer bonding strength by 25%,” explains our senior materials engineer.

For parts requiring both complex geometry and high surface quality, we often use hybrid manufacturing: 3D print the complex core structure then use secondary processes like CNC machining or tumbling to achieve the required surface finish.

Surface Finishing Requirements

- As-printed 3D parts: Typically require post-processing (sanding, polishing, or vapor smoothing) to achieve functional surface finishes

- Injection molded parts: Often ready for use without additional finishing, with surface finishes down to Ra 0.2μm achievable with proper mold design

- Standard tolerances: ISO 2768-m for general applications, ISO 2768-f for higher precision requirements

3. Typical Applications and Goldcattle Case Studies (2025-2026)

This section presents real-world applications and case studies from Goldcattle’s recent projects, demonstrating the practical use of injection molding and 3D printing across different industries.

Automotive Industry

Complex Plastic Components – Intricate geometries produced using 3D printing for prototyping

Case Study: Automotive Interior Parts

- Production volume: 50,000 parts annually

- Material: ABS+PC blend

- Process: Injection molding for production, 3D printing for prototyping

- Cost savings: 60% compared to all-3D printing production

Medical Industry

Injection Molding Application: High-volume production of surgical instruments and disposable medical devices

3D Printing Application: Custom patient-specific surgical guides and medical device prototypes

Recent Project: 3D printed surgical guides for orthopedic procedures, achieving 99.8% component qualification rate in 2025 (internal data).

Consumer Products

- Injection Molding: Mass production of consumer electronics, toys, and household goods

- 3D Printing: Customized consumer products, limited edition items, and personalized accessories

- Material Standards: FDA 21 CFR Part 177 for food contact materials, UL 94 for flammability requirements

4. Cost Control Guide: From Single Parts to Batch Optimization

Cost analysis is critical when choosing between injection molding and 3D printing. This section provides a detailed cost comparison framework and optimization strategies for different production volumes.

| Production Volume | Injection Molding Cost per Part | 3D Printing Cost per Part | Recommended Process |

|---|---|---|---|

| 1-10 parts | $200-500 (including tooling) | $20-100 | 3D Printing |

| 10-100 parts | $50-200 (including tooling) | $15-80 | Depends on complexity |

| 100-1000 parts | $10-50 (tooling amortized) | $10-50 | Depends on volume and complexity |

| 1000+ parts | $1-10 (tooling fully amortized) | $8-40 | Injection Molding |

Cost Formula (For Reference Only)

Total Cost = Material Cost + Machine Time Cost + Tooling Cost + Post-Processing Cost + Quality Control Cost

Injection Molding: High initial tooling cost ($5,000-$100,000) but very low per-part cost for high volumes

3D Printing: No tooling cost but higher machine hourly rates and often additional post-processing

Cost Optimization Strategies

- Small batches (1-50 parts): Use 3D printing to avoid expensive tooling costs

- Medium batches (50-500 parts): Consider rapid tooling for injection molding or hybrid manufacturing

- Large batches (500+ parts): Injection molding is typically more cost-effective

- Complex geometries: 3D printing often more economical despite higher machine costs

5. Common Defect Diagnosis and Solutions

This section identifies common defects in injection molded and 3D printed plastic parts, provides root cause analysis, and offers preventive and corrective solutions.

Injection Molding Defects

Sink Marks and Warpage

Causes: Uneven wall thickness, insufficient packing pressure, improper cooling, material shrinkage

Solutions: Increase packing pressure, optimize cooling channels, adjust wall thickness, use material with lower shrinkage

Prevention: Design uniform wall thickness, use proper gate design, optimize process parameters

Short Shots and Voids

Causes: Insufficient injection pressure, inadequate material flow, blocked gates, material degradation

Solutions: Increase injection pressure, improve gate design, pre-dry material, optimize temperature profile

Prevention: Use proper venting, maintain material quality, optimize mold design

3D Printing Defects

Layer Shifting and Warping

Causes: Improper bed leveling, insufficient bed adhesion, thermal expansion, mechanical vibration

Solutions: Improve bed adhesion (use glue stick or hairspray), optimize bed leveling, enclose printer, adjust printing temperature

Prevention: Proper machine calibration, use heated bed, optimize part orientation

Stringing and Oozing

Causes: Nozzle temperature too high, insufficient retraction, slow travel speed, material degradation

Solutions: Reduce nozzle temperature, increase retraction distance, optimize travel speed, use fresh material

Prevention: Proper temperature calibration, use high-quality filament, optimize retraction settings

Quality Improvement Results

“By optimizing heating temperature profiles and implementing active cooling strategies, we reduced warping defects in 3D printed parts by 15% in 2025,” reports our quality control manager. “For injection molding, implementing in-process monitoring helped reduce scrap rates by 12%.”

6. 2026 Plastic Part Manufacturing Trends and Hybrid Technology Outlook

This section explores the latest trends in plastic part manufacturing, including the growing adoption of hybrid manufacturing, sustainable practices, and emerging technologies.

Hybrid Manufacturing: Injection Molding + 3D Printing

Hybrid manufacturing combines the strengths of both technologies: the high-volume efficiency of injection molding with the design freedom of 3D printing. This approach is rapidly gaining traction in automotive, medical, and consumer products industries.

| Trend | Expected Growth | Key Applications |

|---|---|---|

| Hybrid Manufacturing | 60% growth by 2026 | Automotive components, medical devices |

| Sustainable Plastics | 55% growth by 2026 | Biodegradable materials, recycled resins |

| AI-Enhanced Manufacturing | 50% growth by 2026 | Process optimization, quality prediction |

| Electric Vehicle Components | 75% growth by 2026 | Battery components, lightweight structures |

Industry Forecast (For Reference Only)

“We predict that hybrid manufacturing will represent 35% of plastic part production by 2028, up from just 8% in 2024,” says our chief technology officer. “This shift is driven by the need for both cost efficiency and design flexibility in modern product development.”

The market for sustainable plastic materials is expected to reach $25 billion by 2027, with biodegradable and recycled materials accounting for 20% of total plastic production.

Sustainable Manufacturing Practices

- Biodegradable Materials: Increasing use of PLA, PHA, and other biodegradable polymers in both injection molding and 3D printing

- Recycled Resins: Implementation of closed-loop recycling systems for plastic waste reduction

- Energy Efficiency: New generation machines with improved energy consumption, reducing operational costs by 30%

7. Frequently Asked Questions (FAQ)

Q: When should I choose injection molding over 3D printing for plastic parts?

A: Choose injection molding for high-volume production (1,000+ parts), parts requiring tight tolerances and superior surface finish, and when working with a wide range of engineering plastics. Injection molding is also more cost-effective for large production runs due to economies of scale.

Q: What are the advantages of 3D printing for medical applications?

A: 3D printing enables the production of custom patient-specific medical devices, surgical guides, and anatomical models that would be impossible or prohibitively expensive with traditional manufacturing. It also allows for rapid prototyping of new medical device designs and supports complex internal geometries.

Q: How can I minimize defects in injection molded plastic parts?

A: Key strategies include designing uniform wall thickness, using proper gate and runner design, optimizing process parameters (temperature, pressure, cooling time), maintaining material quality through proper drying and handling, and implementing in-process quality monitoring systems.

Q: What are the regulatory requirements for food contact plastics?

A: Food contact plastics must comply with FDA 21 CFR Part 177 (US), EU 10/2011 (Europe), and GB 4806.7-2023 (China). These regulations specify allowable materials, additives, and migration limits to ensure food safety.

Q: How does cost compare between injection molding and 3D printing for small production runs?

A: For small production runs (1-100 parts), 3D printing is often more cost-effective because it avoids the expensive tooling costs associated with injection molding. However, for very simple parts or when using certain materials, injection molding with rapid tooling may still be competitive.

Conclusion: Choosing the Right Manufacturing Technology for Competitive Advantage

The choice between injection molding and 3D printing depends on multiple factors including part complexity, production volume, tolerance requirements, material selection, and cost considerations.

Decision Framework

- Choose injection molding when: High production volume, tight tolerances, superior surface finish, or wide material selection is required

- Choose 3D printing when: Complex geometries, small production runs, rapid prototyping, or customization is needed

- Consider hybrid manufacturing when: Both cost efficiency and design flexibility are required

At Goldcattle, we recommend a technology-agnostic approach where the manufacturing process is selected based on the specific requirements of each project rather than relying on a single technology.

Ready to Optimize Your Plastic Part Manufacturing?

Share your part requirements with us and receive a free technical evaluation and cost comparison between injection molding and 3D printing.

Contact our engineering team today to get started!

This guide provides general technical information and should be used as a reference only. For specific applications, consult with qualified engineering and manufacturing professionals.