In the vast landscape of modern manufacturing, customized online are quietly emerging as a powerful ally for numerous engineers, product developers, and designers. Today, let’s take an in – depth look at this remarkable service.

First, let’s discuss why more and more people are choosing customized online CNC machining services. In the past, traditional machining methods were not only inefficient but also struggled to ensure high precision. Now, platforms like Xiamen Goldcattle offer customized online CNC machining services through a network of over 10,000 suppliers. This is extremely convenient! Whether the design is simple or complex, they can handle it with ease. Whether you want to quickly produce a prototype, or engage in small – batch or large – batch production, it’s all feasible, and the entire process from placing an order to receiving the goods is guaranteed. Just upload the CAD file to Xiamen Goldcattle’s instant quote engine, and you can immediately get the price, delivery time, and manufacturability feedback, which is very helpful for optimizing the design.

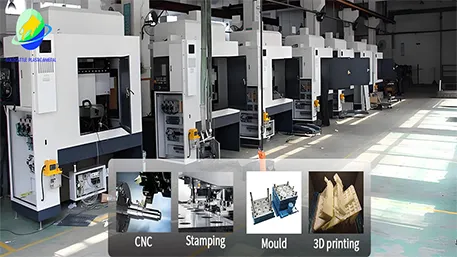

CNC machining, that is, Computer Numerical Control machining, its working principle is not difficult to understand. It uses automated high – speed cutting tools to process metal or plastic raw materials into the desired shape. Common standard CNC machine tools include 3 – axis, 4 – axis, 5 – axis milling machines, lathes, and routing machines. During operation, skilled machinists program the tool paths based on the CAD model, enabling high – precision and high – repeatability cutting of various materials. Whether it’s titanium alloy used in aerospace or plastic components in electronic products, CNC machining can create them with precision, which is why it is popular in various industries.

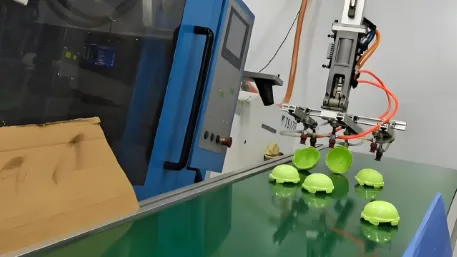

The types of customized online CNC machining services are also quite diverse. Milling services can quickly produce prototypes and production parts; turning services are suitable for processing shaft – like and disk – like parts; routing services can create complex planar contours; and high – volume machining services can meet the needs of large – scale production. Moreover, these services have multiple quality certifications and offer free standard shipping within the United States, which is really considerate.

In terms of material selection, customized online CNC machining services also offer a wide variety. Among metal materials, aluminum alloys such as 6061 and 5052 are lightweight and high – strength, widely used in the aerospace and automotive fields. Stainless – steel alloys like 316/316L have excellent corrosion resistance and are common in the medical and food industries. Among plastic materials, ABS is widely used and affordable; PEEK can replace metals in high – temperature and high – stress environments with excellent performance. If you can’t find a suitable material in the material list, you can choose “Custom” to submit a quote, and a professional team will help handle it.

Tolerances and surface treatments are also important aspects of customized online CNC machining services. Generally, the tolerance of metal parts can be controlled within ±0.005″ (±0.127 mm), and for plastics and composites, it is ±0.010″, and even more precise tolerances can be achieved. There are various surface treatment methods. The standard as – machined surface has tool marks. If you want a smooth surface, you can choose treatments such as shot peening and tumbling. Anodizing can make the parts more corrosion – resistant and come in different colors; powder coating can make the parts more wear – resistant and corrosion – resistant, with a wide range of color options.

However, there are also some things to note during the design process. For example, the internal corner radius should be slightly larger than the standard drill bit size; the bottom corner radius should be smaller than the corner radius; when designing undercuts, choose standard sizes and keep them away from corners; leave tool space for the depth of threaded holes. Also, try to reduce the number of small cuts to lower costs.

The advantages of customized online CNC machining services are very obvious. It has high precision and good repeatability, with a tolerance that can reach ±0.001″ – 0.005″, and it can work continuously for 24 hours to quickly produce parts. It can preserve the mechanical properties of the materials, and there is a wide range of processable materials. Of course, it also faces some challenges, such as high processing costs for complex geometries, high startup costs, and slow and expensive wire – electrical – discharge machining. But overall, its advantages far outweigh these challenges.

The application scenarios of this service are also very extensive. In rapid tooling, it can quickly produce high – precision molds; in rapid prototyping, it can turn ideas into physical objects quickly; in final product production, with high precision and high – quality surface treatment, it can produce high – quality products.

Customized online CNC machining services provide an efficient and precise solution for the manufacturing industry. With the continuous advancement of technology, it is believed that it will play an important role in more fields, bringing more high – quality products to our lives. If you also have machining needs, you might as well try customized online CNC machining services and embark on a journey of efficient manufacturing!