For industries demanding unparalleled precision, speed, and customization in manufacturing, Xiamen Goldcattle stands as a global leader in CNC machining services. With 25 years of expertise, state-of-the-art facilities spanning 1,000–3,000 square meters, and a fleet of over 100 advanced CNC machines—including Mazak 5-axis systems—we deliver high-performance solutions for aerospace, automotive, medical, electronics, and more.

Why Choose Xiamen Goldcattle?

1. Advanced Manufacturing Capabilities

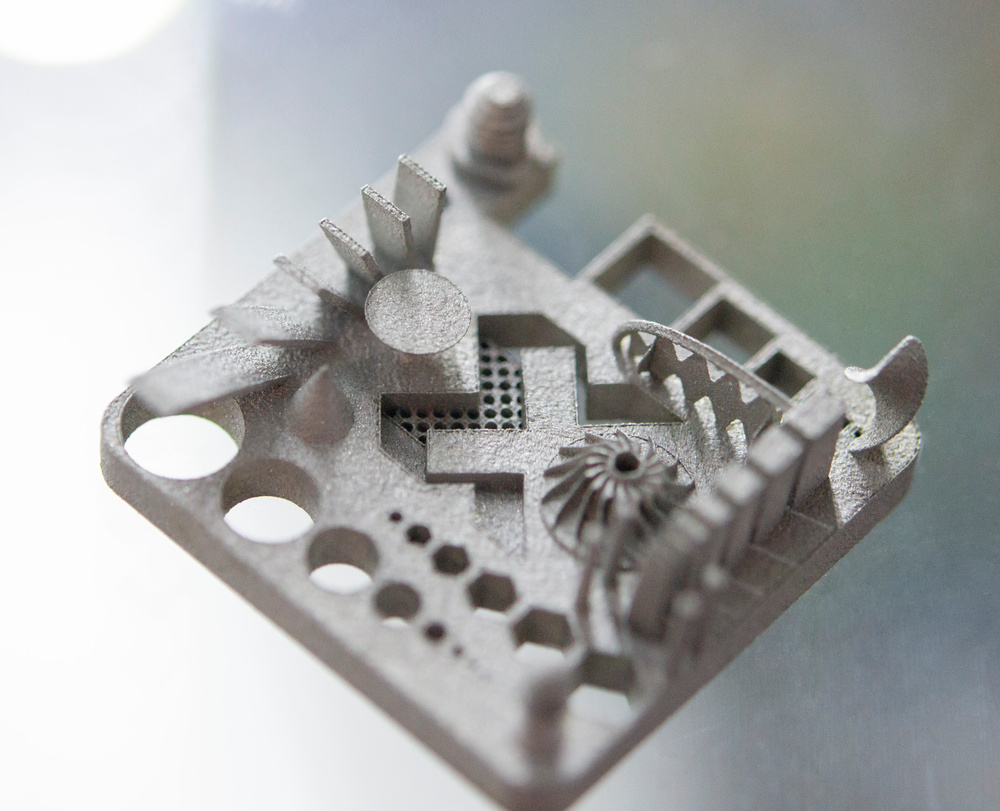

Our facility houses 260 CNC lathes, 200 automatic lathes, and multiple 5-axis CNC machines, enabling us to handle complex geometries with tolerances as tight as ±0.005–0.1 mm. Whether it’s CNC turning, milling, laser cutting, EDM wire cutting, or Swiss-type precision machining, our equipment ensures high repeatability and surface finishes for both metal (e.g., titanium alloys, aluminum, stainless steel) and non-metal materials (e.g., PEEK, engineering plastics).

2. End-to-End Customization

From rapid prototyping to mass production, we offer one-stop solutions:

- Design Optimization: Our ISO 9001-certified engineering team provides DFM (Design for Manufacturing) support to refine your CAD models for cost-efficiency and manufacturability.

- Material Expertise: Work with high-performance materials like S136, NAK80, and 718H tool steels for molds, or specialized alloys for critical components.

- Scalability: Seamlessly transition from prototypes to high-volume production (1–1,000,000+ units) with no compromise on quality.

3. Speed-to-Market Excellence

Time-sensitive projects thrive with our accelerated lead times:

- Standard Delivery: 7–30 business days, depending on order complexity and volume.

- Expedited Service: Prioritized scheduling for urgent requirements, supported by 24/7 production capabilities.

4. Rigorous Quality Assurance

Every component undergoes multi-stage inspections (IQC, PQC, FQC, OQC) using advanced metrology tools like CMMs (Coordinate Measuring Machines), spectrographs, and salt spray testers. Our ISO 9001:2008 certification and 100% quality guarantee ensure compliance with international standards, reducing rework risks and supply chain delays.

5. Global Trust, Local Expertise

With 600+ skilled employees and a client base spanning North America, Europe, Asia, and beyond, we’ve delivered precision parts for Fortune 500 companies and niche innovators alike. Our 24/7 multilingual support ensures seamless communication, from initial RFQ to post-delivery technical assistance.

Industries We Serve

- Aerospace: High-strength, lightweight components with AS9100-compliant tolerances.

- Medical: Biocompatible implants and surgical tools meeting ISO 13485 standards.

- Automotive: Durable engine parts, transmission systems, and EV components.

- Electronics: Micro-sized, ultra-thin housings and connectors for consumer tech.

Commitment to Sustainability

By optimizing material usage with AI-driven nesting software and recycling 95% of machining waste, we minimize environmental impact while reducing costs for clients.

Partner with Xiamen Goldcattle Today

Elevate your manufacturing strategy with a partner that combines 25 years of CNC mastery, cutting-edge technology, and unwavering dedication to quality.

Visit www.xmgoldcattle.com to upload your design, request a quote, or consult our engineers. Your precision, our passion.

Xiamen Goldcattle Industrial & Trade Co., Ltd.

SO 9001:2008 Certified | 100% Quality Guarantee | Global Shipping

Contact: Charlie Que | Tel: +86-18150097490 | Email: charlie@plasticmetalparts.com