1.Background

Xiamen Goldcattle Industrial & Trade Co., Limited, founded in 2011, is a company with rich experience and professional technology in the field of precision plastic injection molded parts. With its advanced production equipment, strict quality management system and excellent customer service, the company has won the trust and praise of many domestic and foreign customers. Recently, a well-known company focusing on medical device production, Kangtai Medical Equipment Co., Ltd, chose Xiamen Goldcattle as its supplier of precision plastic injection molded parts to meet its new product development needs.

2.Purchase Requirements

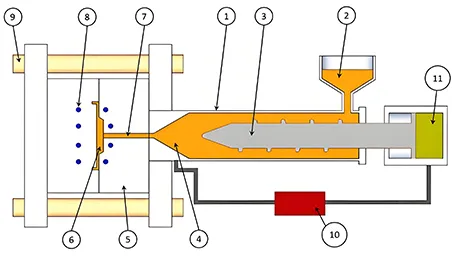

Kangtai Medical Equipment Co., Ltd. is developing a new portable medical testing instrument, which needs to be made of high-precision, abrasion-resistant and corrosion-resistant plastic materials for both the housing and internal components. Specific requirements are as follows:

Material Requirements: Plastic materials that are environmentally friendly, non-toxic, and meet medical industry standards, such as PC, ABS, etc., should be used.

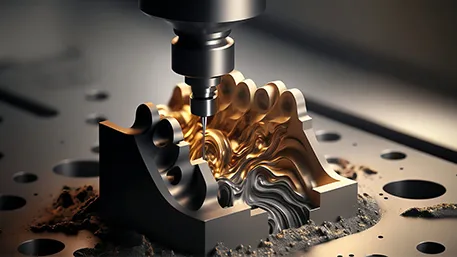

Dimensional accuracy: the dimensional tolerance of the shell and internal components should be controlled within ± 0.02mm to ensure the precision and stability of the instrument.

Surface treatment: the shell needs to be matte to improve the feel and reduce reflective interference; internal components need to be anti-scratch, anti-corrosion treatment.

Batch demand: 500 sets are required at the initial trial production stage. If the product passes the verification, it will enter the mass production stage, and the annual demand is expected to reach 10,000 sets.

3.Procurement Process

Initial communication: Kangtai Medical Equipment Co., Ltd. contacted its sales team through Xiamen Goldcattle’s official website and explained the procurement requirements in detail, and Xiamen Goldcattle’s sales engineers responded quickly by providing preliminary proposal and quotation.

Technical Evaluation: The technical teams of both parties held several video conferences to discuss the product design, material selection, production process, etc. Xiamen Goldcattle’s team of engineers made a number of optimization suggestions based on their rich experience to ensure that the product meets the needs of Comtrend.

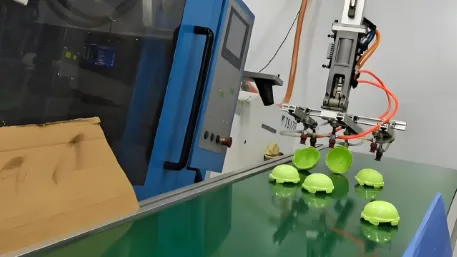

Sample production and testing: After confirming the design, Xiamen Goldcattle quickly started the sample production process. After several mold trials and adjustments, the samples were finally produced to meet the requirements. Comtech conducted strict tests on the samples, including size measurement, performance test, environmental protection test, etc., which all met the expected standards.

Contract signing and mass production: After confirming that the samples were qualified, both parties signed a formal procurement contract. xiamen Goldcattle quickly started the mass production process and arranged a professional quality control team to strictly monitor every step of the production process to ensure stable product quality.

4.Cooperation Achievements

Through the joint efforts of both parties, the new products of Kangtai Medical Devices Co., Ltd. were successfully launched on the market and gained wide acclaim in the market, and the precision plastic injection molding parts provided by Xiamen Goldcattle not only met the design requirements of the products, but also greatly improved the quality and stability of the products. At the same time, both parties have established a good relationship of trust during the cooperation process, laying a solid foundation for future long-term cooperation.

Conclusion

This cooperation fully demonstrates Xiamen Goldcattle’s professional strength and quality service in the field of precision plastic injection molded parts. In the future, Xiamen Goldcattle will continue to uphold the principle of “customer first, quality first” to provide more customers with high-quality customized services, and jointly promote the transformation and upgrading of the manufacturing industry and high-quality development.