In the field of injection molding processing, Xiamen Goldcattle has won wide acclaim in the industry for its excellent technical strength, advanced processing equipment, professional staff team and high quality customized services.Xiamen Goldcattle provides customized injection molding processing parts services with a customer-oriented approach and is committed to meeting customers’ individual needs. The enterprise has a professional design team and engineers who can provide one-stop service from product design, mold development, injection molding production to finished product inspection according to customer’s specific specifications, materials, performance and other requirements.

1.Injection Molding Technology

Xiamen Goldcattle is constantly innovating and breaking through in injection molding processing technology, and has mastered a number of advanced injection molding techniques and technology. The company focuses on technological innovation and process optimization to continuously improve production efficiency and product quality. Through the introduction of intelligent, automated production equipment and technical means, it realizes the precise control and efficient operation of the injection molding process.

1.1 Technical Advantages

High-precision processing: adopting high-precision CNC processing technology and high-quality mold steel to ensure that the precision of molds and parts reaches micron level.

Multi-material selection: Supporting a variety of material selection and processing, including plastic, metal, etc., to meet the needs of different application scenarios.

Efficient production: Introducing advanced injection molding machines and automated production lines at home and abroad to realize efficient and stable production process and shorten the delivery cycle.

Strict quality control: establish a perfect quality control system to control all aspects of raw materials, production process and finished product inspection to ensure product quality.

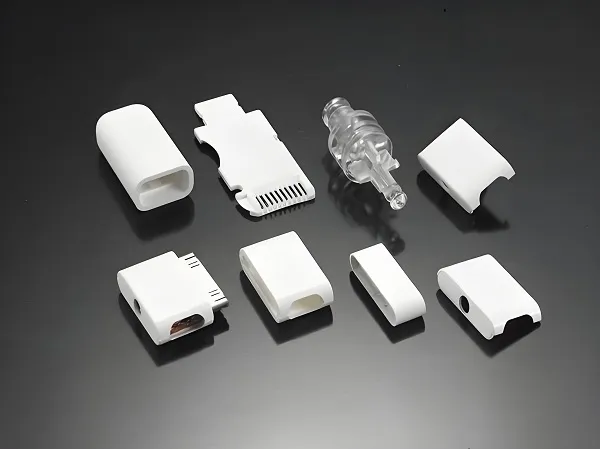

2.Customized injection molding parts service

Xiamen Goldcattle’s custom injection molding parts service focuses on meeting customers’ individual needs, providing one-stop solutions from product concept design to final product delivery. Through advanced injection molding processing technology and equipment, combined with a professional team and strict quality control system, we ensure that each customized part meets or even exceeds customers’ expectations.

2.1 Service Process

Demand communication: Communicate with customers in depth to clarify the specific needs of customized parts, including size, material, performance, quantity, delivery date and other key information.

Program design: according to customer needs, the professional design team to carry out preliminary program design, including three-dimensional modeling, structural analysis, material selection, etc., to ensure the rationality and feasibility of the design program.

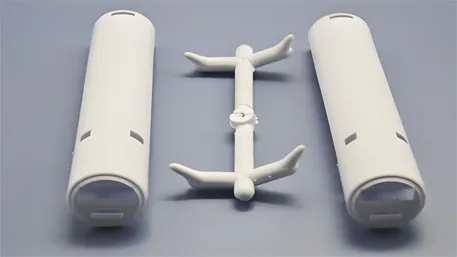

Mold development: Based on the design scheme, experienced mold engineers carry out mold design and manufacturing. High-precision CNC processing technology and high-quality mold steel are used to ensure the precision and durability of the mold.

Sample production: Sample production is carried out using the developed molds to verify the correctness of the design scheme and the feasibility of the production process. At the same time, make necessary adjustments and optimization according to customer feedback.

Mass production: After the samples are confirmed to be correct, we enter the mass production stage. Through advanced injection molding machines and automated production lines, we realize efficient and stable production process.

Quality Inspection: Strict quality inspection is carried out on the produced parts, including size measurement, appearance inspection, performance test, etc., to ensure that each part meets customer requirements and industry standards.

Packing and shipping: Pack the qualified parts and ship them according to the agreed delivery date. At the same time, we provide perfect after-sales service to ensure that any problems encountered by customers in the course of use can be solved in time.

3.Injection molding processing equipment

Xiamen Goldcattle has introduced advanced injection molding machines and supporting equipment from home and abroad, and constructed an efficient and stable injection molding processing line. The enterprise pays attention to the selection and maintenance of the equipment to ensure that the equipment is in the best working condition. At the same time, the enterprise has also established a perfect equipment management system and operating procedures to ensure the safe and stable operation of the equipment.

4.Staffing

Xiamen Goldcattle has a professional and efficient team, including design engineers, mold engineers, injection molding technicians, quality inspectors and other professionals in various positions. The team members have rich practical experience and professional knowledge, and can provide professional technical support and service for customers. The company focuses on talent cultivation and team building work, and continuously improves the comprehensive quality and business ability of the staff.

Xiamen Goldcattle’s custom injection molded parts service is oriented to customers’ needs, featuring high-precision machining, multi-material selection, efficient production and strict quality control, providing customers with all-round, high-quality solutions. Through our professional team and advanced equipment, we ensure that each customized part meets customers’ expectations and requirements.

Custom Injection Molded Parts FAQ

Q1: What is the customization process?

A: The customized process includes demand communication, program design, mold manufacturing, sample making, mass production, quality inspection and packaging shipment. After in-depth communication between the company and the customer to clarify the demand, the professional team will carry out program design and mold manufacturing, followed by sample making and mass production, and finally through quality inspection and packaging shipment to ensure that the customer can receive the satisfactory products in a timely manner.

Q2: What is the delivery time for customized parts?

A: The delivery period depends on the complexity and quantity of the customized parts as well as the production schedule. Enterprises will negotiate with customers to determine the delivery period and strictly follow the contracted time for production and delivery.