1. Basic Understanding of Polycarbonate Materials

1.1 What is Polycarbonate (PC)?

1.2 Core Properties of Polycarbonate

- High Light Transmittance: With a transparency of up to 90%, it is almost as transparent as glass, making it the preferred material for “transparent” designs.

- Impact Resistance: Its impact strength is 250 times that of ordinary glass and 30 times that of acrylic sheets, earning it the title of “transparent metal”.

- High Temperature Resistance: It can withstand a maximum continuous use temperature of up to 120°C, far exceeding that of transparent plastics such as PMMA (acrylic) and PS.

- Weather Resistance: With the addition of ultraviolet absorbers, it can effectively resist the effects of ultraviolet rays in sunlight, avoiding yellowing and embrittlement during long-term outdoor use.

1.3 Is Polycarbonate Suitable for Molding?

- Fluidity: In its molten state, polycarbonate (PC) is relatively viscous but can still fill molds well to form various shapes.

- Plasticity: As a typical linear thermoplastic polymer material, PC can theoretically be recycled and reprocessed multiple times, aligning with the sustainable development concept of the circular economy.

2. Detailed Explanation of Main Polycarbonate Molding Processes

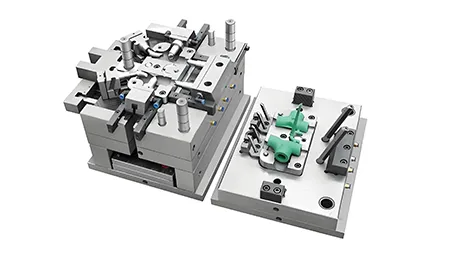

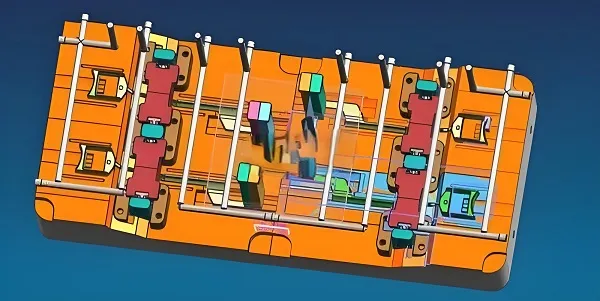

2.1 Injection Molding (Most Commonly Used Process)

Process Principle

Core Process (Critical Steps Marked)

- Raw Material Drying: PC is extremely sensitive to moisture; dampness can cause bubbles and silver streaks. Drying at 120°C for 3-4 hours is required.

- Melting and Plasticizing: Dried pellets are melted through electric heating in the barrel and shear force from the screw.

- Injection and Mold Filling: The screw advances slowly to inject molten PC into the mold at high speed.

- Pressure Holding and Shrinkage Compensation: After injection, pressure is maintained to replenish material lost due to cooling shrinkage, preventing sink marks.

- Cooling and Setting: The product is cooled and solidified through the cooling water channels in the mold.

- Mold Release and Part Removal: The mold is opened, and the ejector mechanism pushes out the product.

Key Parameters

- Temperature: The barrel temperature is controlled at 280-320°C; the mold temperature is controlled at 80-110°C (excessively high temperatures cause mold sticking, while excessively low temperatures lead to high internal stress).

- Injection Pressure and Speed: High speed and pressure facilitate mold filling, but excessively high values cause flash and internal stress.

- Pressure Holding Pressure and Time: Proper pressure holding is key to eliminating sink marks.

Typical Applications

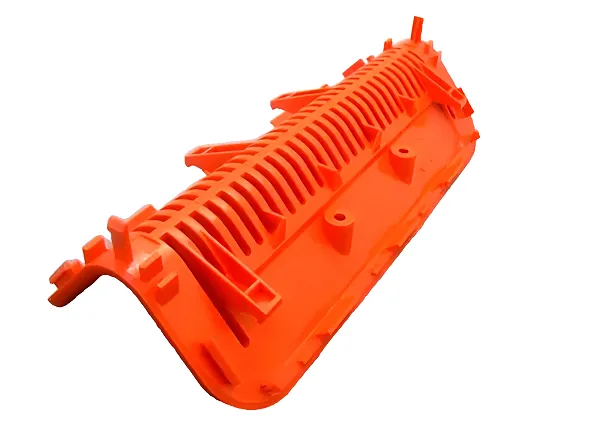

2.2 Extrusion Molding

Process Principle

Core Process

Suitable Products

2.3 Blow Molding

Process Principle

Classification and Application Scenarios

- Extrusion Blow Molding: The parison is extruded continuously at a slow speed, suitable for producing large-capacity containers (e.g., 5-gallon drinking water buckets).

- Injection Blow Molding: The parison is formed by injection molding, with high dimensional accuracy, making it ideal for small-caliber bottles (e.g., sports water bottles).

Typical Applications

2.4 Other Special Molding Processes

- Thermoforming: Extruded PC sheets are heated and softened, then pressed against the mold surface by vacuum suction or air pressure, and formed after cooling.

- 3D Printing Molding (FDM): PC wires are used, melted by the heating head of a 3D printer, and stacked layer by layer to produce customized parts.

3. Common Issues and Solutions in Polycarbonate Molding

3.1 Common Molding Defects and Causes

|

Defect Type

|

Main Causes

|

|

Bubbles / Silver Streaks

|

Insufficient drying of raw materials (moisture vaporization), poor mold venting

|

|

Cracks

|

Excessively low mold temperature, rapid cooling (concentrated internal stress), sharp corners in product design

|

|

Surface Defects

|

Sink marks (insufficient pressure holding), scratches (poor mold finish / difficult mold release)

|

3.2 Targeted Solutions

- Raw Material Pretreatment: Use a dehumidifying dryer to ensure the dew point is below -40°C.

- Mold Optimization: Add venting grooves, polish the mold cavity to a mirror finish, and optimize the gate and cooling water channels.

- Process Parameter Adjustment: Increase the mold temperature to reduce internal stress; optimize the pressure holding curve; reduce the injection speed to minimize shear stress.

3.3 Key Precautions

- Raw Material Purity: Avoid mixing impurities or materials of different grades to prevent phase separation and performance degradation.

- Mold Maintenance: Clean the mold regularly to prevent oil stains and rust from affecting appearance and mold release.

- Environmental Cleanliness: Maintain a clean production environment to prevent dust from contaminating dried raw materials.

4. Safety and Environmental Standards for Polycarbonate Molding

4.1 Safety Compliance Standards

- Food-Contact Grade: Must comply with National Standard GB 4806.7 to ensure no harmful substances (e.g., BPA) migrate into food.

- Medical Grade: Must pass biocompatibility tests such as USP Class VI or ISO 10993, and be molded in a cleanroom with a class of 10,000 or higher (to ensure sterility).

- Electronics and Electrical Field: Must meet UL94 flame retardant grade requirements to avoid degradation of flame retardant performance due to material degradation.

4.2 Environmental Production Requirements

- Energy Consumption Control: Adopt energy-saving technologies such as servo motors and electromagnetic heating; use circulating cooling towers for the cooling water system.

- Pollutant Treatment: Install VOCs collection devices at the exhaust ports of extrusion / injection molding machines; classify, crush, and granulate scrap materials and defective products for reuse.

- Recycled PC Molding: Test the purity, molecular weight, and yellowing index of recycled materials before use; appropriately increase the processing temperature during secondary molding to compensate for degradation.

4.3 Clarification of Common Safety Misconceptions

- Bisphenol A (BPA) Issue: Modern production processes for food-contact grade PC have controlled BPA residues to levels far below the EU limit of 0.05mg/kg, making them safe for use.

- High-Temperature Use Limit: Injection-molded PC water cups can withstand temperatures of approximately 110°C, while extruded PC sheets have slightly better heat resistance; neither should be used in microwave ovens or for long-term storage of boiling oil (to avoid deformation or substance migration).

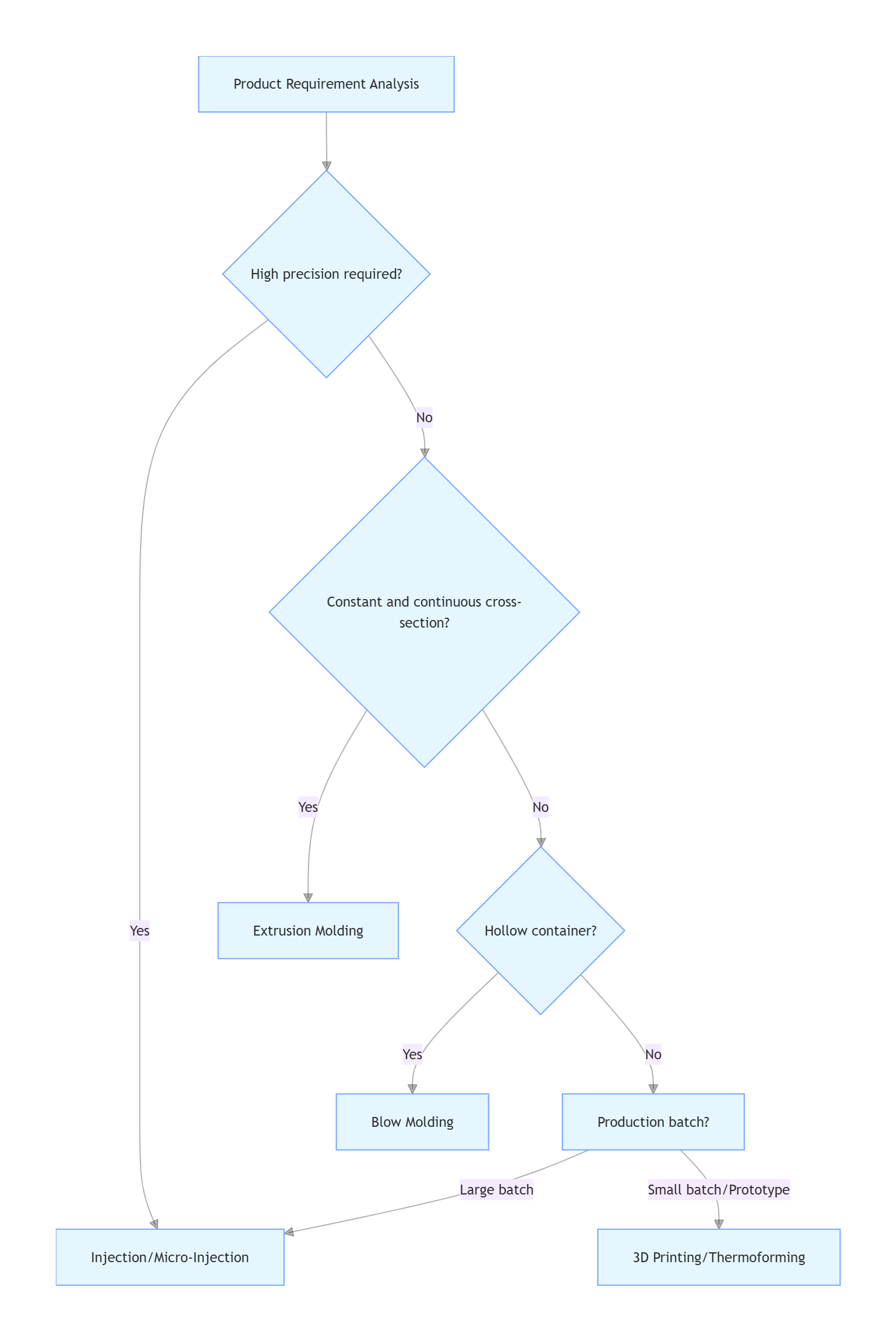

5. Practical Selection and Case Analysis of Polycarbonate Molding

5.1 Core Principles of Process Selection

|

Selection Criterion

|

Recommended Process

|

Case Description

|

|

Product Precision

|

High precision → Injection / Micro-Injection; Ordinary → Extrusion

|

Electronic connectors → Micro-injection; Decorative panels → Extrusion

|

|

Production Batch

|

Large batch → Injection; Small batch → 3D Printing

|

Mobile phone casings → Injection; Prototypes → 3D Printing

|

|

Cost Budget

|

Low cost → Extrusion; High cost → Injection

|

Protective panels → Extrusion; Automotive precision parts → Injection

|

5.2 Typical Scenario Selection Cases

Case 1: Household Baby Food Containers

- Requirements: Food safety, impact resistance, mass production

- Selection: Injection Molding

- Key Design: Use large rounded corners for mold edges (to avoid stress cracking); polish the mold cavity to a mirror finish (to ensure appearance quality)

Case 2: Outdoor Advertising Light Box Panels

- Requirements: High light transmittance, UV resistance, large size

- Selection: Extrusion Molding

- Advantage: 30% lower cost and higher efficiency compared to the “extrusion + thermoforming” solution

Case 3: Customized Robot Joint Accessories

- Requirements: Small batch (50 pieces), complex structure, high strength

- Selection: 3D Printing Molding (FDM)

- Material Requirements: Use glass fiber-reinforced PC wires (to improve strength); optimize the printing direction (to reduce interlayer peeling)

5.3 Selection Aids

Process Selection Flowchart

Common Issues Comparison Table

|

Product Pain Point / Requirement

|

Recommended Process

|

Key Parameter Adjustment Suggestions

|

|

Withstand 120°C high temperature

|

Injection / Extrusion

|

Choose high heat-resistant grades; increase mold temperature to reduce internal stress

|

|

Transparent and defect-free

|

Injection / Extrusion

|

Fully dry raw materials; polish mold cavity to mirror finish; optimize pressure holding

|

|

Large-size thin-walled parts

|

Thermoforming

|

Use extruded PC sheets; control the uniformity of heating temperature

|

|

Small-batch complex structures

|

3D Printing

|

Choose high-strength PC materials; heat the platform to 100°C to prevent warping

|