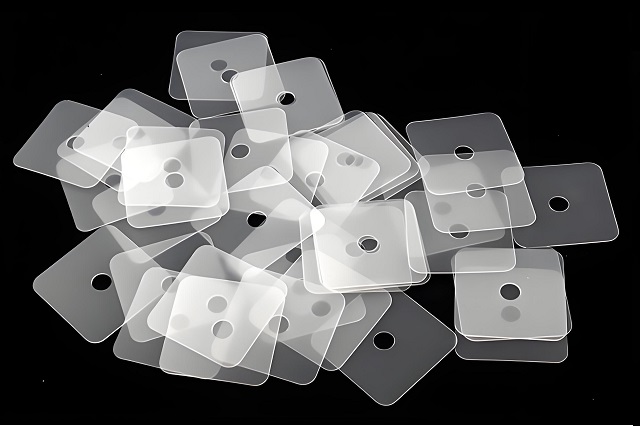

Square plastic gasket, as a common sealing and supporting element in industrial production and daily life, is widely used in many fields such as mechanical equipment, electronic equipment, automobile manufacturing, construction and so on for its good insulation, corrosion resistance, abrasion resistance and easy processing. In order to meet the diversified needs of different industries and customers for gasket size, material and performance, we provide professional customized square plastic gasket service.

1. Customized square plastic shims process

Demand communication: Firstly, our professional team will communicate with you in depth to understand your specific needs, including gasket size, thickness, material, quantity, use of the environment and so on.

Design: According to your needs, we will provide a variety of design options for you to choose, or customize the exclusive design according to your requirements.

Material Selection: We provide a variety of plastic materials for you to choose from, including but not limited to polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), nylon (PA), polytetrafluoroethylene (PTFE), etc., to ensure that the gasket meets your performance requirements.

Price Confirmation: After the design scheme and material selection are confirmed, we will provide you with a detailed quotation, including material cost, processing cost, transportation cost, etc.

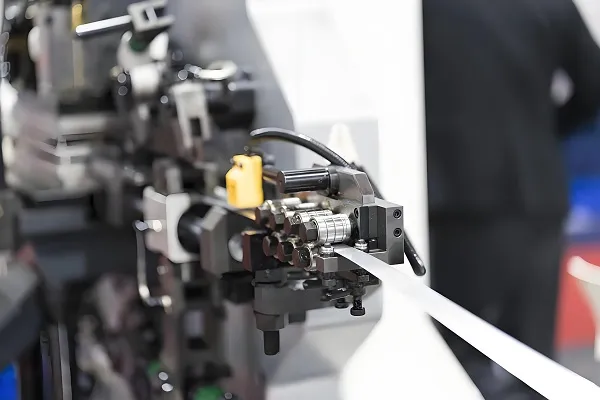

Production and Processing: After confirming the order, we will start the production and processing to ensure that the quality and precision of the gaskets meet your requirements.

Quality Inspection: After the production is completed, we will carry out strict quality inspection on the gaskets, including size measurement, performance test, etc., to ensure the quality of the products.

Delivery service: after passing the test, we will provide packaging, transportation and after-sales service according to your requirements.

2. Production process of square plastic shims

Material preparation: according to the design program, select and prepare the required plastic materials.

Mould making: according to the size of the gasket and design requirements, make special injection mold.

Injection molding: the plastic material is heated and melted, injected into the mold, and then cooled and cured to form the gasket.

Post-processing: Trimming, cutting, grinding and other post-processing of the injection molded gasket to ensure that the size and shape meet the requirements.

Quality Inspection: The gaskets are subjected to quality inspection such as size measurement and performance test to ensure the quality of the products.

Packing and shipping: Packing the qualified gaskets and arranging shipping according to your requirements.

3. Square plastic shims technology

We adopt advanced injection molding technology, combined with precise mold design and manufacturing, to ensure the dimensional accuracy and shape stability of the gaskets. Meanwhile, we also provide a variety of surface treatment technologies, such as spraying, plating, etching, etc., to meet your special requirements on the appearance and performance of the gaskets.

4. Square Plastic Shim Material

We offer a wide range of plastic materials for you to choose from, including but not limited to:

Polypropylene (PP): good corrosion resistance, abrasion resistance and high thermal stability.

Polyethylene (PE): excellent flexibility and impact resistance, suitable for low temperature environments.

Polyvinyl chloride (PVC): good insulation and corrosion resistance, suitable for electrical equipment and chemical industry.

Nylon (PA): high strength and abrasion resistance, suitable for high strength and abrasion resistance requirements.

Polytetrafluoroethylene (PTFE): excellent high temperature resistance, corrosion resistance and low coefficient of friction, suitable for high temperature and corrosive environment.

5. Different materials square plastic gasket use

Polypropylene (PP) gasket: commonly used in food packaging, water treatment, chemical equipment and other fields.

Polyethylene (PE) gaskets: suitable for sealing and supporting in low temperature environment, such as cold storage equipment, freezer, etc..

Polyvinyl chloride (PVC) gaskets: widely used in electrical insulation, pipe connection, chemical storage tanks and other fields.

Nylon (PA) gaskets: suitable for high strength and wear-resistant requirements, such as automobile manufacturing, machinery and equipment.

Polytetrafluoroethylene (PTFE) gaskets: commonly used in high temperature, high pressure and corrosive environment sealing, such as petrochemical equipment, chemical pipelines and so on.

Customized Square Plastic Gasket FAQ

Q: What size square plastic gasket can I customize?

A: We can customize any size of square plastic gasket according to your needs, including but not limited to standard size and special size.

Q: How long does it take to customize square plastic shims?

A: The time it takes to customize square plastic shims depends on the size and quantity of the shims, material selection, and the production process. Typically, it can take anywhere from a few days to a few weeks from design to delivery.

Q: How do I choose the material for my square plastic shims?

A: When choosing the material for square plastic shims, you need to consider the environment, temperature, pressure and corrosiveness of the shims. Our professional team will advise you on material selection based on your specific needs.

Q: How to calculate the price of customized square plastic shims?

A: The price of customized square plastic shims depends on factors such as shim size, quantity, material selection and processing difficulty. We will provide a detailed quotation based on your specific needs.

We are committed to providing you with high-quality customized square plastic shims services to meet your diverse needs. If you have any questions or needs about customized square plastic shims, please feel free to contact us!