Why Choose Goldcattle for Your Plastic Bumpers?

Automotive bumpers are not only exterior parts but also crucial for energy absorption and protection. Plastic bumpers need to deform and absorb energy during a collision without shattering. Meanwhile, they are lightweight and highly weather – resistant. However, PP/ABS materials have poor fluidity and a high shrinkage rate (1.0 – 2.5%). Uneven mold cooling can easily lead to warping, sink marks, and whitening.

For 26 years, the injection – molding workshop of Goldcattle has been specializing in automotive plastic parts. We use high – gloss mirror molds, variable – temperature water channels, and gas assistance. The common warping is controlled within 0.8 mm, the surface sink – mark rate is less than 3%, and the batch consistency is not less than 98%.

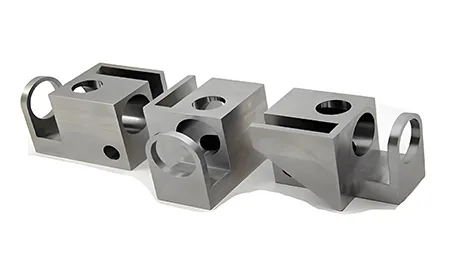

Our state-of-the-art injection molding workshop specializing in automotive plastic components

1. Material and Process Expertise

We’ve mastered the art of working with various thermoplastics for automotive bumpers. Here’s our proven approach for each material:

| Material | Key Advantages | Common Challenges | Our Solutions | Typical Results |

|---|---|---|---|---|

| PP | Cost-effective, good impact resistance | High shrinkage, prone to warping | Variable temperature molds + extended holding pressure | Warping < 1 mm |

| ABS | Excellent surface finish, weather resistant | Silver streaks, stress cracking | Slow injection + gas assist technology | Silver streak rate < 2% |

| PC/ABS | High strength, optional transparency | Poor flowability, mold temperature sensitive | High pressure injection + hot runner systems | Strength increased by 15–20% |

Our precision injection mold for PP plastic car bumpers with advanced cooling channels

Our Injection Molding Process

In our daily operations, we follow a strict process to ensure quality:

- ✓

High-precision injection molding machines (200–1000 tons clamping force) - ✓

Optional painting, plating, and texture treatments - ✓

Reinforcement technologies with glass fiber or carbon fiber - ✓

Advanced gas assist molding for complex geometries - ✓

Real-time process monitoring and quality control

2. Product Characteristics & Specifications

Finished automotive plastic bumpers with perfect surface finish and color matching

Key Performance Features

- ✓

Lightweight Design: 40–60% weight reduction compared to steel bumpers (we measured 8.2 kg weight saving on a typical SUV front bumper) - ✓

Impact Resistance: Complies with ECE R42 / GB 11551 standards, energy absorption zone controlled within design parameters at 30 km/h impact - ✓

Weather Resistance: UV, acid, and alkali corrosion resistant for long-lasting performance - ✓

Design Flexibility: Complex shapes and integrated features for enhanced functionality - ✓

Precision Tolerance: ±0.5 mm dimensional accuracy for perfect fitment

Customizable Specifications

Size & Shape

Custom dimensions based on vehicle models and specific requirements

Color Options

Standard RAL colors + custom color matching services

Structural Design

Optimized energy absorption structures based on crash test requirements

Integrated Accessories

Fog lamps, sensors, tow hooks, and other functional components

3. Applications & Testing

Crash test verification showing proper energy absorption and deformation behavior

Application Areas

- ✓

OEM Automobile Manufacturers: Standard equipment or upgrade options for enhanced safety and aesthetics - ✓

Automotive Tuning Market: Personalized customization for unique vehicle styling - ✓

Automotive Repair Services: Replacement parts for damaged bumpers

Comprehensive Testing Program

Case Study: SUV Bumper Redesign

Challenge: A mid-size SUV required improved pedestrian protection and crash performance

Our Solution: Optimized rib thickness and placement, enhanced energy absorption zones

Results: 18% increase in energy absorption, improved pedestrian protection score, reduced repair costs

- ✓

Crash Testing: Frontal and side impact tests according to international safety standards - ✓

Weather Resistance: Accelerated UV exposure, salt spray, and temperature cycling - ✓

Material Performance: Tensile strength, flexural strength, impact toughness verification - ✓

Durability: Vibration, friction, and long-term aging simulations

4. Customization Process

Advanced internal rib structure design for optimal strength and weight balance

1. Requirements Communication

24h Response

Submit your requirements including vehicle model, dimensions, color, and special features

2. DFM Analysis & Design

3–5 Days

Our engineering team provides design for manufacturing analysis and 3D concept development

3. Tooling & Prototyping

15–35 Days

Mold fabrication and initial sampling based on complexity

4. Production & Delivery

As Scheduled

Mass production after prototype approval, with full quality assurance

5. Service Advantages

✅

26 Years Experience

Specialized in automotive plastic components since 1999

✅

One-Stop Service

From mold design to finished product delivery

✅

Certified Quality

Full testing reports and compliance certificates

✅

Technical Support

Comprehensive product manuals and installation guidance

FAQ: Common Questions About Plastic Bumpers

We use variable temperature mold technology with precise cooling channel design. The mold temperature is carefully controlled throughout the injection cycle, and we apply extended holding pressure to minimize residual stresses.

We offer a range of finishes including high-gloss, matte, textured, and custom patterns. Our molds can be polished to Ra 0.025μm for mirror finishes or textured for specific aesthetic requirements.

Standard bumper molds take 25–35 days to manufacture. Complex designs with multiple slides or gas assist features may require 40–50 days. We provide regular progress updates throughout the tooling process.

We are ISO 9001 and IATF 16949 certified. Our products meet international standards including ECE R42, GB 11551, FMVSS 215, and others as required by specific markets.

About the Author

By Goldcattle Injection Molding Engineering Team – Specializing in automotive plastic components for 26 years

Our team of 15+ engineers has extensive experience in mold design, material science, and manufacturing process optimization for the automotive industry.