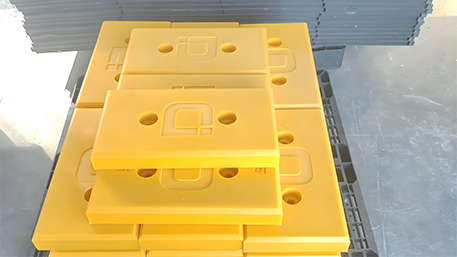

Plastic wear plate, as a kind of high-performance engineering plastic sheet, is widely used in many fields such as machinery manufacturing, chemical industry, food processing, mining and so on with its excellent wear resistance, impact resistance, corrosion resistance and light weight and high strength. It can not only effectively extend the service life of the equipment, but also improve production efficiency and reduce maintenance costs.

1.Plastic wear plate production process

Raw material selection and pretreatment: According to customer needs and application scenarios, choose suitable plastic raw materials, such as polypropylene (PP), polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC) or nylon (PA) and so on. Raw materials need to go through pre-treatment steps such as drying, screening and mixing to ensure their quality and stability.

Mold design and manufacturing: According to the size, shape and thickness requirements of the wear-resistant plates, special extrusion or injection molds are designed and manufactured. The precision and durability of the molds are crucial to the quality of the wear-resistant plates.

Molding process: adopt extrusion, injection or calendering molding process to process the pre-treated plastic raw materials into wear-resistant plates. During the molding process, parameters such as temperature, pressure and speed need to be strictly controlled to ensure the dimensional accuracy and physical properties of the wear-resistant plates.

Post-processing and finishing: The molded wear-resistant plate is subject to post-processing operations such as trimming, deburring, cutting, punching, etc. to meet the specific needs of customers. Meanwhile, surface modification, such as spraying and printing, can also be carried out to improve the appearance quality and durability of the wear-resistant plates.

Quality inspection and testing: Strict quality inspection and performance testing of wear-resistant plates, including testing of wear resistance, impact resistance, corrosion resistance, hardness, thickness and other indexes, to ensure that they meet the relevant standards and customer requirements.

Packaging and shipment: The qualified wear-resistant plates will be packaged with necessary product description and warranty information, ready to be shipped to customers.

2.Customization of plastic wear-resistant plate

Demand analysis: Communicate with customers in depth to understand their application scenarios, wear-resistant requirements, size specifications, color and other specific needs.

Design program: according to the customer’s needs, design the wear-resistant plate size, shape, thickness and material and other parameters, and provide preliminary design drawings and samples.

Sample making and testing: Make samples according to the design scheme and conduct actual testing to verify the key performance such as wear resistance and impact resistance.

Optimization and Adjustment: Based on the test results and customer feedback, optimize and adjust the design scheme until it meets all the customer’s requirements.

Mass production: After confirming that the design scheme is correct, mass production will be carried out and the consistency and stability of product quality will be ensured.

After-sales service: Provide perfect after-sales service, including product consultation, technical support, maintenance and replacement, etc. to ensure customer satisfaction.

3.Plastic wear-resistant plate material introduction

Material: polypropylene (PP), polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), nylon (PA) and so on.

Characteristics:

Strong abrasion resistance: these plastic materials have excellent abrasion resistance and can withstand high-frequency friction and abrasion, extending the service life of the equipment.

Good impact resistance: good impact resistance, able to maintain structural integrity and stability when subjected to external impact.

Strong corrosion resistance: able to resist the erosion of a variety of chemical substances, suitable for corrosive environments.

Lightweight and high strength: compared with traditional metal materials, plastic wear plates are lighter, while having high strength and stiffness.

4. Characteristics of plastic wear plates of different materials

Products: PP wear plate, PE wear plate, PU wear plate, PVC wear plate, PA wear plate and so on.

Data:

PP wear plate:

Abrasion resistance: ≥5000 rpm (Taber abrasion test)

Density: 0.90-0.91g/cm³

Tensile strength: ≥30MPa

Use temperature range: -30℃ to +110℃.

PE wear-resistant plate:

Abrasion resistance: ≥8000rpm (Taber abrasion test)

Density: 0.92-0.96g/cm³

Impact toughness: ≥20kJ/m²

Use temperature range: -40℃ to +60℃.

PU wear-resistant plate:

Abrasion resistance: ≥10000rpm (Taber abrasion test)

Density: 1.1-1.3g/cm³

Elastic recovery rate: ≥90%

Use temperature range: -20℃ to +80℃

PVC wear-resistant plate:

Abrasion resistance: ≥6000

Use temperature range: -40℃ to +100℃

Customized Plastic Wear Plates FAQ

Q1: What are the advantages of plastic wear plates over metal wear plates?

A: Plastic wear plates have the advantages of light weight, corrosion resistance, easy processing, lower cost, etc. Meanwhile, they can provide better abrasion resistance and impact resistance, and are suitable for a variety of complex environments.

Q2: How to choose the right plastic wear plate material?

A: When choosing plastic wear plate materials, you need to consider application scenarios, wear resistance requirements, temperature range, chemical corrosion and other factors, and consult the advice of professionals.

Q3: What is the customization process of plastic wear plate?

A: The customization process of plastic wear-resistant plate includes steps such as demand analysis, design scheme, sample making and testing, optimization and adjustment, mass production and after-sales service.

Q4: How to extend the service life of plastic wear plates?

A: Regularly clean and maintain the surface of the wear plate, avoid contact with sharp objects to minimize unnecessary friction and wear, and avoid prolonged exposure to high temperatures or corrosive environments.

Q5: What is the price of plastic wear plates?

A: The price of plastic wear plate is affected by many factors such as material, size, thickness, degree of customization, etc. The specific price should be negotiated and determined according to the customer’s demand and order quantity.