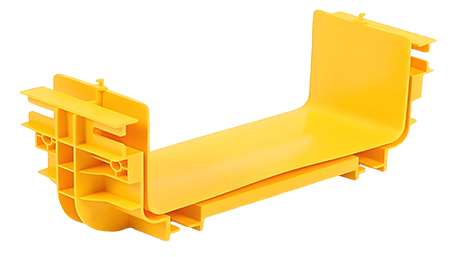

ABC plastic molded parts, as an indispensable part of modern industry, are widely used in automotive, electronics, medical devices, toys and many other fields due to its excellent physical properties, processing convenience and cost-effectiveness.ABC plastics, usually referred to as a kind of thermoplastic with good comprehensive performance, can be produced in various shapes and sizes through injection molding, blow molding, extrusion, and other molding processes, to meet the The ABC plastic molded parts can be produced in various shapes and sizes through injection molding, blow molding, extrusion and other molding processes to meet diversified market demands.

1.ABC plastic molded parts production process

Raw material preparation: Select high quality ABC plastic granules to ensure the purity and stability of the raw material to provide the basis for the subsequent molding process.

Mold design and manufacturing: according to the product design drawings, accurately design and manufacture injection molds to ensure the dimensional accuracy and appearance quality of molded parts.

Molding process: The pre-treated ABC plastic granules are fed into the injection molding machine, injected into the mold cavity through heating and melting, and the molded parts are obtained after cooling and curing.

Post-processing: deburring, trimming, inspection and other processes are carried out on the molded parts to ensure that the products meet the quality requirements.

Packing and shipping: Pack the qualified molded parts with necessary instructions and labels, ready to be shipped to customers.

ABC plastic molded parts customization

Demand Communication: Communicate with customers in depth to understand the product’s usage scenarios, functional needs, appearance requirements, etc., to provide a basis for the subsequent design and production.

Design and development: According to customer’s requirements, product design and mold design, including the details of size, shape, wall thickness, demolding slant, etc.

Sample making and testing: Make samples and conduct performance tests, such as tensile strength, bending strength, impact toughness, etc., to ensure that the product meets the design requirements.

Mass production: After confirming that the samples are error-free, mass production will be carried out to ensure product quality and production efficiency.

After-sales service: provide technical support and after-sales service, including product use guidance, maintenance and replacement suggestions, etc., to ensure customer satisfaction.

2.ABC plastic molding parts material

Good physical properties: high tensile strength, bending strength and impact toughness, able to withstand certain external forces and impacts.

Excellent processing properties: easy to melt and injection molding, wide range of processing temperature, short molding cycle, high production efficiency.

Good chemical stability: good corrosion resistance to most acids, alkalis, salts and other chemicals.

Good surface gloss and color: easy to color and surface treatment, can produce a variety of colors and textures of molded parts.

3.Application of ABC plastic molded parts in different fields

Products: automotive parts, electronic housings, medical equipment parts, toy parts, etc.

Data:

Automotive parts: ABC plastic molded parts are widely used in automotive interiors and exteriors, such as instrument panels, door handles, bumpers, etc. They are lightweight, high strength and impact resistant.

Electronic shell: ABC plastic molding parts have good insulation and processing performance, suitable for making shells of various electronic products, such as cell phones, computers, TVs, etc.

Medical device parts: ABC plastic molding parts are used in medical devices to make surgical instruments, infusion sets, blood bags and other parts, which are non-toxic, tasteless and corrosion-resistant.

Toy parts: ABC plastic molded parts are colorful, safe and non-toxic, which are ideal for making toys, such as blocks, puzzles, models and so on.

Customized ABC plastic molding parts FAQ

Q1: How long is the production cycle of ABC plastic molded parts?

A1: The production cycle depends on factors such as the complexity of the product, the manufacturing time of the mold and the production lot. Generally speaking, it takes 1-2 weeks from design to sample making, while mass production needs to be determined according to the order quantity.

Q2:How to ensure the dimensional accuracy of ABC plastic molded parts?

A2: The key to ensure the dimensional accuracy lies in the design and manufacture of the mold. Adopting high-precision mold manufacturing technology and strict production process control can ensure that the dimensional accuracy of the molded parts meets the design requirements.

Q3: Are ABC plastic molded parts environmentally friendly?

A3: ABC plastic is an environmentally friendly thermoplastic that can be recycled. During the production process, we strictly comply with environmental regulations to reduce the emission of waste and pollutants.

Through the above introduction, we hope to help you better understand the information about customized ABC plastic molded parts. Please feel free to contact us if you have any questions or needs.