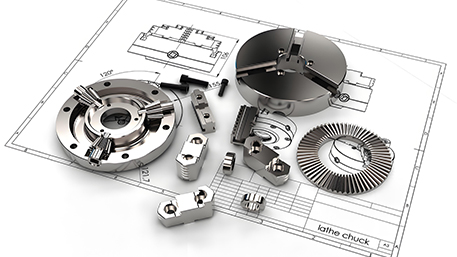

Automotive CNC parts are automotive parts precisely machined by computer numerical control (CNC) technology. With the rapid development of the automotive industry, CNC machining technology plays an increasingly important role in the manufacture of automotive parts.CNC machining not only improves the accuracy and surface quality of the parts, but also dramatically improves the production efficiency and flexibility, which meets the automotive industry’s needs for high-quality, high-efficiency, low-cost parts manufacturing.

1. The role of CNC in the automotive industry

Improve part accuracy: CNC machining technology can accurately control the tool’s trajectory and cutting parameters, so as to ensure that the size, shape and positional accuracy of automotive parts to meet the design requirements.

Enhance production efficiency: CNC machining has a high degree of automation and intelligent features, can significantly shorten the processing cycle of parts, improve production efficiency.

Enhance material utilization: CNC machining technology can accurately control the amount of material removal according to the shape and size of the part, reduce material waste and improve material utilization.

Promote innovative design: CNC machining technology can process automobile parts with complex shapes and structures, providing more innovative space for automobile designers.

2. CNC machining automobile parts technology

Five-axis linkage processing: five-axis CNC machine tools can simultaneously control the movement and rotation in five directions, realizing the processing of complex shapes and angles, and improving the accuracy and surface quality of parts.

High-speed cutting technology: High-speed cutting technology shortens the machining time by increasing the cutting speed and feed rate, while maintaining the high precision and surface quality of the parts.

Microfabrication technology: Microfabrication CNC machining technology can process tiny automotive parts features, such as microscopic holes and microscopic slots, to meet the requirements of automotive parts for precision and detail.

Laser cutting technology: Laser CNC cutting technology utilizes a laser beam for non-contact cutting, which is suitable for cutting thin plate materials and high-precision parts.

3. Advantages of CNC machining auto parts

High precision: CNC machining technology can ensure that the size, shape and positional accuracy of automobile parts meet the design requirements, improving the performance and safety of automobiles.

High quality: CNC machining process can strictly control the cutting parameters and machining temperature, to avoid thermal deformation and residual stress and other problems, to ensure the high quality of parts.

High efficiency: CNC machining has a high degree of automation and intelligent features, can significantly shorten the processing cycle of the parts, improve production efficiency.

Flexibility: CNC machining technology can adapt to different shapes, sizes and materials of automotive parts processing needs, providing customized solutions.

4. CNC machining auto parts materials

| Material | Properties | Applications |

|---|---|---|

| Aluminum Alloy | Lightweight, good corrosion resistance, good machinability | Engine parts, body panels, wheels |

| Steel | High strength, good wear resistance, low cost | Suspension parts, chassis components |

| Stainless Steel | High corrosion resistance, good machinability | Exhaust systems, fuel systems |

| Titanium Alloy | Lightweight, high strength, excellent corrosion resistance | High-performance engine parts |

| Carbon Fiber | Lightweight, high stiffness, good fatigue resistance | Body panels, racing car components |

5. CNC machining auto parts service

Customized design: according to customer needs, provide a full range of services from design to manufacturing, including 3D modeling of parts, process planning, machining and manufacturing.

Quality control: establish a strict quality control system, conduct strict inspection of raw materials, processing and finished products to ensure the quality of parts meets customer requirements.

Rapid Response: Provide rapid response and efficient production services to ensure that customers can obtain the required parts on time.

Technical Support: Provide technical support and after-sales service, including installation and commissioning of parts, maintenance and replacement, and technical consultation.

6. Xiamen Goldcattle auto parts advantages

Professional team: We have an experienced team in designing, processing and quality control of auto parts, which can provide customers with high-quality and high-efficiency services.

Advanced equipments: Introducing advanced CNC machining equipments and testing technologies from home and abroad to ensure that the machining precision and quality of the parts reach the international advanced level.

Strict standards: Follow ISO/TS 16949 and other automotive industry quality management system standards to ensure that the quality of parts meets the requirements of the automotive industry.

Customized service: Provide personalized and customized service to meet the diversified needs of customers.

7. Xiamen Goldcattle processing automotive parts equipment

5-axis CNC machine: with high-precision and high-efficiency machining capability, suitable for the machining of complex shaped parts.

High-speed cutting machine: Shorten the machining time by increasing the cutting speed and feed rate, while maintaining the high precision and surface quality of the parts.

Laser Cutting Machine: Utilizes a laser beam for non-contact cutting, suitable for cutting thin sheet materials and high-precision parts.

3D Printer: Manufacturing parts by printing layer by layer, suitable for complex shapes and tiny parts.

8. Xiamen Goldcattle Auto Parts Evaluation

Xiamen Goldcattle has won wide recognition and praise in the field of auto parts manufacturing for its excellent quality, professional service and efficient production capacity. Customers generally rate its automotive parts highly and consider its parts to be characterized by high precision, high quality, high reliability and good cost performance. Meanwhile, customers are also satisfied with its customized service, quick response and perfect after-sales service.

Customized Automotive CNC Parts Service FAQ

Q: How to customize automotive CNC parts?

A: You can provide information such as design drawings, material requirements, and quantity of the parts by contacting our professional team, and we will customize the design and processing and manufacturing according to your needs.

Q: How to calculate the price of CNC machining auto parts?

A: The price is usually calculated based on the size, shape, material, quantity and machining difficulty of the part. You can contact our sales team for detailed quotation information.

Q: How do you guarantee the quality of auto parts?

A: We have established a strict quality control system to monitor quality throughout the whole process, from raw material procurement, machining process control to finished product inspection, to ensure that the quality of the parts meets customer requirements and industry standards.

Q: What is the delivery time?

A: Delivery time is usually determined by factors such as the processing difficulty and quantity of the parts. We will try our best to shorten the production cycle to ensure that customers can get the required parts on time. In case of emergency, please contact us in advance and we will try our best to provide you with quick response service.

Q: Do you provide technical support and after-sales service?

A: Yes, we provide comprehensive technical support and after-sales service, including installation and debugging of parts, maintenance and replacement, and technical consulting, etc., to ensure that our customers receive timely support and assistance in the process of use.