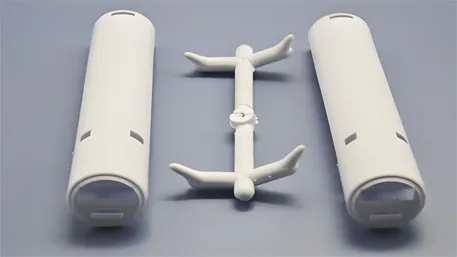

Overview of CN Architectural Components

Customized architectural component services play a crucial role in the modern construction industry. With technological advancements, particularly the widespread application of Computer Numerical Control (CNC) technology, customized architectural component services have not only enhanced production efficiency but also significantly met personalized demands. This article will provide a detailed introduction to the role of CNC in the construction field, CNC technology for architectural components, the advantages of CNC-processed architectural components, applicable materials, standard requirements for architectural components, an introduction to processing equipment, as well as an evaluation of Xiamen Goldcattle’s architectural components. Additionally, an English table listing materials for CNC-processed architectural components and a FAQ section on customized architectural component services will be included.

1. The Role of CNC in the Construction Field

(1) Digital Design and Model Making

CNC machining technology enables efficient and precise digital design and model making. By importing designs from computer software into CNC machines, precise processing of architectural components is achieved, improving the accuracy of design and manufacturing, and accelerating the speed of architectural production.

(2) Processing of Complex Shapes

CNC machining technology precisely controls the path and speed of the cutting tool, enabling efficient processing of components with complex shapes. This not only improves the precision of component processing but also reduces costs and shortens processing cycles.

(3) High-Quality Surface Treatment

CNC machining technology uses precise control of the cutting tool to achieve high-quality processing and treatment of component surfaces, meeting the required smoothness and precision of the design.

(4) Personalized Custom Production

CNC machining technology enables personalized production of components through computer programming, making personalized architectural designs possible.

(5) Precise Construction and Automated Control

CNC machining technology can be integrated with Building Information Modeling (BIM) to achieve precise control and management of the construction process, improving construction efficiency and quality.

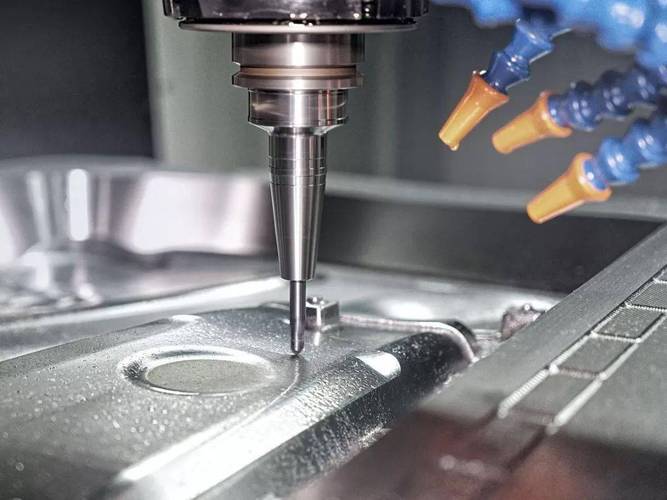

2. CNC Technology for Architectural Components

(1) Operating Principle

The operating principle of CNC processing technology is to import drawings of parts created in CAD software into the control system of the CNC machine tool. The control system processes the digital quantization and controls the movement trajectory of the machine tool through a computer to achieve precise processing.

(2) Hardware and Software

The control system of a CNC machine tool mainly consists of hardware and software. Hardware includes the numerical control system, motors, sensors, tools, etc.; software includes the operating system, programming software, processing programs, etc.

(3) Processing Range

CNC processing technology can machine various complex-shaped parts, whether curved surfaces, irregular shapes, or porous structures, with ease, providing greater design freedom.

3. Advantages of CNC-Processed Architectural Components

(1) High Precision

CNC processing technology achieves high-precision part processing, controlling processing errors within a small range and ensuring the dimensional and shape accuracy of architectural components.

(2) High Efficiency

CNC processing technology offers higher production efficiency. The automated processing process reduces the time and errors associated with manual operations, enabling the rapid completion of large volumes of architectural component processing tasks.

(3) Diversity

CNC processing technology can produce a variety of complex-shaped architectural components, meeting personalized demands and making products more diverse and personalized.

(4) Stable Quality

The CNC processing process is precisely controlled by a computer, reducing the influence of human factors on processing quality and ensuring the stable and reliable quality of architectural components.

4. Materials for CNC-Processed Architectural Components

| Material | Key Characteristics |

|---|---|

| Aluminum 6061 | Medium strength, good corrosion resistance, weldable, but less corrosion resistant in saltwater or other chemicals. |

| Aluminum 7075 | High strength, easy to machine, good wear resistance, strong corrosion resistance, excellent oxidation resistance. |

| Brass | Corrosion resistance decreases with increasing zinc content. |

| Pure Copper | High electrical and thermal conductivity, good corrosion resistance in various environments. |

| 303 Stainless Steel | Good machinability, resistance to burning and corrosion, used for applications requiring easy machining and high surface finish. |

| 304 Stainless Steel | Good machinability and toughness, more corrosion resistant in most normal (non-chemical) environments. |

| 316 Stainless Steel | Good heat resistance and corrosion resistance, stable in chloride and non-oxidizing acid environments. |

| 45 Steel | Good comprehensive mechanical properties, low hardenability, prone to cracking when water quenched. |

| 40Cr Steel | Widely used in machinery manufacturing, with good comprehensive mechanical properties, low-temperature impact toughness, and low notch sensitivity. |

| Nylon | Wear-resistant, heat-resistant, chemical-resistant, flame-retardant, easy to process. |

| PEEK | Excellent stability and impact resistance, used in compressor valves, piston rings, seals, etc. |

5. Standard Requirements for Architectural Components

The standard requirements for architectural components mainly include strength and stability, corrosion resistance, and the ability to adapt to special environments and climatic conditions. When selecting and manufacturing architectural components, it is crucial to strictly follow relevant manufacturing processes and testing standards to ensure component quality meets requirements.

6. Introduction to Architectural Component Processing Equipment

The processing equipment for architectural components mainly includes CNC machines, precision cutting equipment, welding equipment, etc. These machines ensure the dimensional and shape accuracy of architectural components through high-precision processing and assembly, while improving production efficiency and quality stability.

7. Evaluation of Xiamen Goldcattle’s Architectural Components

Xiamen Goldcattle enjoys a good reputation in the field of architectural components. Its products are renowned for high quality, high precision, and personalized customization services. Customers generally have high evaluations of Xiamen Goldcattle’s architectural components, praising their reliable quality, superior performance, and ability to meet various complex and personalized needs.

8. FAQ on Customized Architectural Component Services

Q1: What are customized architectural component services?

A1: Customized architectural component services refer to designing and manufacturing architectural components that fully meet clients’ specific needs and project requirements.

Q2: What are the advantages of customized architectural components?

A2: Customized architectural components offer advantages such as high precision, high efficiency, diversity, and stable quality, meeting personalized demands and enhancing product competitiveness.

Q3: What materials are used for customized architectural components?

A3: Customized architectural components can use various materials, including aluminum alloy, stainless steel, brass, pure copper, nylon, PEEK, etc. The specific choice depends on the technical requirements and operating environment of the product.

Q4: What is the processing workflow for customized architectural components?

A4: The processing workflow for customized architectural components includes digital design, drawing import, CNC processing, quality inspection, and other steps, ensuring product precision and quality.

Through customized architectural component services, clients can obtain architectural components that fully meet their needs and project requirements, enhancing product competitiveness and market position.