In modern manufacturing, hardware accessories serve as vital components of various machinery and products, and their quality and precision directly impact the performance and appearance of the products. Customized hardware accessories services can produce hardware components that meet specific customer needs and specifications through precision processing technology and equipment.

I. Overview of CNC Hardware Accessories

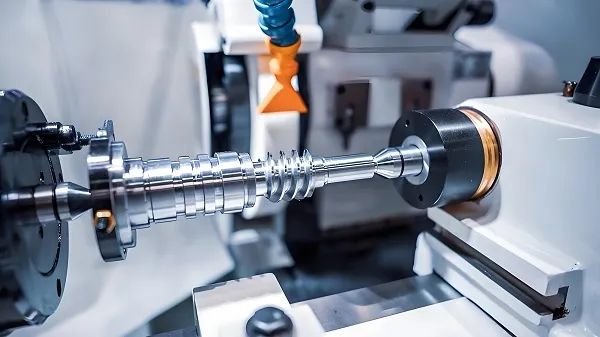

CNC (Computer Numerical Control) processing technology is a core technology in customized hardware accessories services. It utilizes pre-programmed computer instructions to control machine tools for automated processing, achieving high precision and efficient production.

II. The Role of CNC in the Hardware Field

- Enhanced Processing Precision: CNC machine tools can precisely control the movement trajectory and cutting parameters of the cutting tool according to preset programs, achieving micron-level processing precision and meeting the high precision requirements of hardware accessories.

- Increased Production Efficiency: CNC processing can be continuous and automated, reducing manual intervention and waiting time, significantly improving production efficiency, and shortening delivery cycles.

- Complex Shape Processing: CNC processing equipment can programmatically achieve complex shape processing, whether it’s curved surfaces, irregular shapes, or porous structures, all can be easily handled, providing greater design freedom for hardware accessories.

- Stable Product Quality: Since CNC processing is based on programmed control, each processing run maintains a high degree of consistency, ensuring stable product quality and reducing defective rates.

III. CNC Technology for Hardware Accessories

- Processing Workflow: The process of CNC-machined hardware accessories includes pre-processing preparations (such as confirming the program sheet and preparing cutting tools), clamping and positioning of workpieces, clamping and tool setting, formal processing, and self-inspection after processing. Each step must strictly adhere to operational norms to ensure processing quality and safety.

- Equipment and Technology: CNC machine tools are the core equipment for precision hardware accessory processing, and their precision and performance directly affect processing quality. Additionally, advanced processing technologies and processes are key factors in improving processing efficiency and quality.

IV. Advantages of CNC-Processed Hardware Accessories

- High Precision: CNC processing technology can achieve micron-level processing precision, meeting the needs of high-precision applications.

- High Efficiency: CNC processing can be continuous and automated, reducing manual operation time and errors, and improving production efficiency.

- Flexibility: CNC processing can easily handle complex shapes and structures, with only program modifications needed to meet different part processing requirements.

- Stability: CNC processing equipment offers high stability and consistency, ensuring consistent quality in mass-produced hardware accessories.

V. Materials for CNC-Processed Hardware Accessories (English Table)

| Material | Rigidity | Machinability | Rust Resistance | Cost |

|---|---|---|---|---|

| Aluminum Alloy | High | Good | Moderate | Low |

| Stainless Steel | High | Good | Excellent | Medium |

| Brass | Moderate | Excellent | Moderate | Low |

| Copper | Moderate | Good | Excellent | Medium |

VI. Standard Requirements for Hardware Accessories

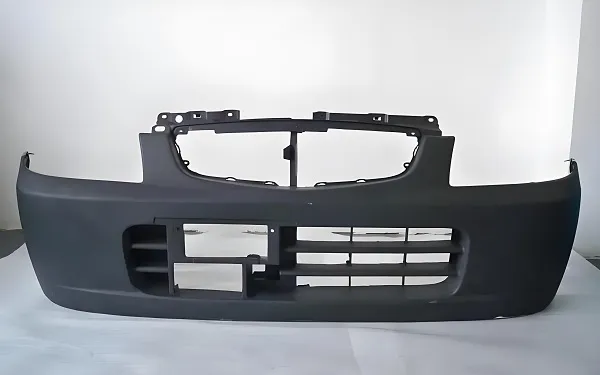

- Appearance Quality Standards: The appearance of hardware accessories should have no obvious scratches, dents, oxidation spots, etc. The surface should be smooth and free of burrs or other sharp parts.

- Structural Quality Standards: The structure of hardware accessories should be sturdy and should not exhibit looseness, deformation, or other issues. Especially for angles or curved parts, there should be no cracks or deformation.

- Durability Standards: Hardware accessories should withstand long-term use and should not exhibit easy breakage, deformation, rusting, or other issues.

VII. Introduction to Hardware Processing Equipment

- Lathes: Lathes are one of the most basic equipment in hardware processing and can be used to process various shaft parts, sleeves, internal and external threads, and various surface shapes. CNC lathes offer high precision, efficiency, and flexibility.

- Milling Machines: Milling machines can be used to process various planes, curved surfaces, and cams. CNC milling machines offer high automation and processing efficiency.

- Drilling Machines: Drilling machines are commonly used equipment for processing hole-type parts and can drill various sizes of holes, as well as process various internal and external threads. CNC drilling machines offer high automation and processing efficiency.

- Shearing Machines: Shearing machines are used in hardware processing to cut metal sheets and can cut metal sheets of different materials and thicknesses. Hydraulic shearing machines offer high cutting precision and speed.

- Punch Presses: Punch presses are used in hardware processing to punch metal materials and can process various shapes of parts, such as covers, brackets, frames, etc. CNC punch presses offer high automation and processing efficiency.

VIII. Evaluations of Xiamen Goldcattle Hardware Accessories

As a professional customized hardware accessory service provider, Xiamen Goldcattle boasts rich processing experience and advanced production equipment. Its CNC processing technology is superb, capable of producing high-precision, high-quality hardware accessories. Additionally, Xiamen Goldcattle emphasizes environmental protection and sustainable development, adopting eco-friendly materials and processes to reduce waste emissions and environmental pollution. Customers have highly praised its product quality and service attitude.

Customized Hardware Accessories Service FAQ

Q1: What is the delivery time for customized hardware accessories?

A1: The delivery time depends on the order quantity, complexity, and production equipment scheduling. Generally, we will complete production and delivery within 1-2 weeks after receiving the order.

Q2: How do you ensure the quality of customized hardware accessories?

A2: We utilize advanced CNC processing technology and equipment and strictly adhere to operational norms. From raw material procurement, the processing process, to finished product inspection, we conduct rigorous quality control to ensure that product quality meets customer requirements.

Q3: Do you offer sample testing or pilot production services?

A3: Yes, we offer sample testing or pilot production services so that customers can verify product quality and performance before placing a formal order.

Q4: Do you support personalized customization?

A4: Yes, we offer personalized customization services, whether it’s shape, size, material, or precision requirements, all can be customized according to customer requirements.

Through this detailed introduction, we hope you have a deeper understanding of customized hardware accessory services. If you have any questions or needs, please feel free to contact us, and we will be happy to serve you.