Customized railing hardware refers to the process of tailoring the hardware required for railings according to customer needs and specific application scenarios. This includes design, material selection, manufacturing and surface treatment to ensure that the hardware matches perfectly with the overall style, functional requirements and usage environment of the balustrade.

What are the processes of customized railing hardware?

The process of customized railing hardware mainly includes the following steps:

Design: According to the style, functional requirements and usage environment of the balustrade, design the shape, size and connection mode of the hardware. The strength, durability and aesthetics of the hardware need to be considered in the design process.

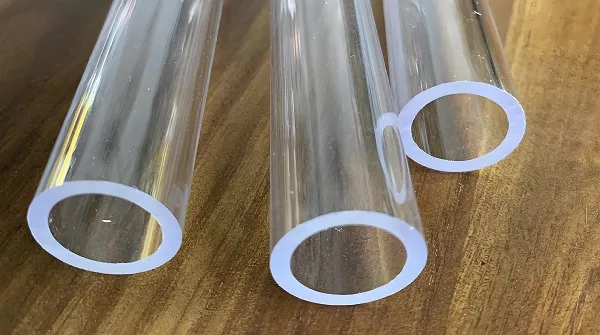

Selection of materials: according to the design requirements and customer needs, select the appropriate materials. Common materials include stainless steel, aluminum alloy, zinc alloy, iron and so on. Stainless steel is favored for its good corrosion resistance, strength and aesthetics.

Manufacturing: Stamping, casting, forging, machining and other processes are used to manufacture hardware. Among them, stamping process is suitable for hardware with large quantity and simple shape; casting and forging are suitable for hardware with complex shape and high strength requirement.

Surface treatment: surface treatment of hardware to improve its corrosion resistance, aesthetics and durability. Common surface treatment methods include electroplating, spraying and polishing. Electroplating can provide bright metal luster and anti-corrosion properties; spraying can give the hardware rich colors and texture; polishing can make the hardware surface more smooth and delicate.

What are the commonly used materials for customized railing hardware?

Commonly used materials for customized railing hardware mainly include:

Stainless steel: with excellent corrosion resistance, strength and aesthetics, it is the preferred material for railing hardware. Stainless steel hardware usually has a bright metallic luster and is not easy to rust.

Aluminum alloy: with the advantages of light weight, high strength and good corrosion resistance, it is suitable for occasions where weight reduction is required. Aluminum hardware usually has good weather resistance and processing performance.

Zinc alloy: It has high strength and hardness, and is easy to process and mold. Zinc alloy hardware usually has exquisite appearance and good durability.

Iron: A traditional material with good strength and moldability. However, iron hardware is susceptible to rust and requires rust prevention treatment.

What are the characteristics of customized railing hardware?

The characteristics of customized railing hardware mainly include:

High strength: customized hardware is usually made of high-quality materials with high strength and hardness, capable of withstanding large forces and impacts.

Corrosion resistance: the surface-treated hardware has good corrosion resistance, which can resist the erosion of harsh environment and prolong the service life.

Aesthetics: customized hardware can be personalized according to customer needs, including shape, size, color and other aspects to meet different aesthetic needs.

Durability: The hardware is carefully manufactured and surface treated to provide good durability and withstand long-term use and wear and tear.

Easy to install: customized hardware is usually designed with reasonable connection methods, which is easy to install and maintain, and reduces construction difficulties and costs.

Conclusion

Customization of railing hardware is a comprehensive work, involving many aspects such as design, material selection, manufacturing and surface treatment. Through customization, it can meet the individual needs of different customers for railing hardware and improve the overall quality and aesthetics of the railing. At the same time, high-quality hardware can also improve the safety and durability of the balustrade, bringing users a better experience.