Thank you for choosing us as your brass CNC machined parts manufacturing partner. The purpose of this brochure is to introduce our expertise in CNC machining of brass, advanced technology, high-end equipment, production cycle and the wide range of products, to ensure that your project can achieve the best quality from the selection of raw materials to the delivery of the final product.

1.High quality brass material

Brass is an alloy of copper and zinc, with excellent electrical and thermal conductivity, corrosion resistance and good machinability, it is ideal for CNC machining. We offer a wide selection of brass materials, including H62 (ordinary brass), H65 (brass with higher zinc content), H70 (high copper brass), HPb59-1 (leaded brass with good cutting and machining properties), etc. Each of these materials has its own unique physical and chemical properties, which are able to meet the needs of different application scenarios. We provide the most suitable brass material recommendation according to customer’s specific requirements and budget to ensure the quality and performance of machined parts.

2.Advanced CNC machining technology

We adopt advanced CNC machining technology, combined with CAD/CAM software, to realize high-precision and high-efficiency parts processing. The main process includes:

Design and Programming: According to the design drawings or 3D models provided by customers, use professional software to carry out 3D modeling of parts and machining path planning to ensure machining accuracy and efficiency.

CNC milling: Utilizing high-precision CNC milling machine, we carry out precision milling on brass material to realize the processing of complex shapes.

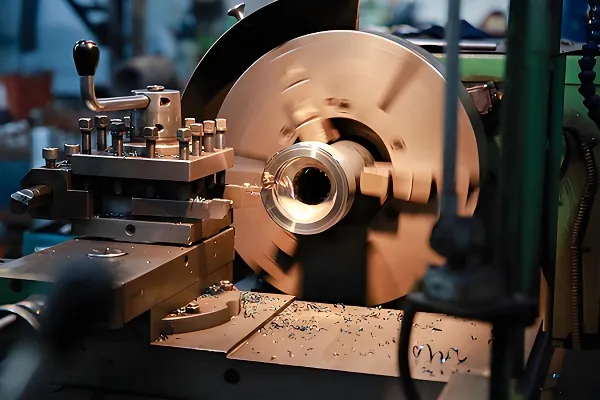

CNC Turning: Through CNC lathe, rotary body machining is carried out on brass bar material, which is suitable for the production of shaft and sleeve parts.

Drilling & Tapping: Using CNC drilling machines or machining centers, brass parts are accurately drilled and threaded.

Surface treatment: Provide various surface treatment services such as polishing, plating, spraying, etc. to enhance the beauty and durability of the parts.

3.High-end production equipment

We are equipped with industry-leading CNC machining equipment, including but not limited to:

High-precision five-axis linkage machining centers, capable of handling complex three-dimensional shapes and improving machining precision and efficiency.

High-speed CNC milling machines, suitable for large-volume, high-efficiency parts processing.

CNC lathe series, covering production needs from small precision parts to large structural parts.

Laser cutting machine, suitable for rapid cutting of thin sheet brass materials.

Coordinate measuring machine to ensure accurate measurement and quality control of processed parts.

4.Production cycle

The production cycle of CNC machined brass parts mainly depends on the complexity and quantity of the parts as well as the required surface treatment process. Generally speaking, the cycle time from design confirmation to finished product delivery is about 7-14 days. We are committed to providing detailed production progress reports after the project has been initiated to ensure that customers can track the project status in real time and communicate in a timely manner to resolve any potential problems. For urgent orders, we will provide expedited service as much as possible according to the factory’s production capacity.

5.Product Coverage

Our brass CNC machined parts service is widely used in many industry sectors, including but not limited to:

Electronic communication: manufacturing of electronic components such as connectors, terminals, heat sinks, etc.

Automotive manufacturing: processing of automotive parts, sensor housings, and decorative parts.

Medical equipment: precision manufacturing of surgical instruments, medical equipment components.

Aerospace: processing of precision parts, sensors, connectors.

Watch & Jewelry: Manufacturing of watch cases, bracelets, ornaments and other fine parts.

Precision Instruments: Processing of optical instruments, measuring instrument parts.

Architectural decoration: manufacturing of architectural hardware such as door handles, decorative parts, lamps and lanterns.

Conclusion:

We know that every processing is a deep understanding and precise response to customer needs. Therefore, we promise to provide one-stop service, from demand analysis, design and development to production delivery and post maintenance, accompanying every customer throughout the whole process to ensure that every customer can obtain a satisfactory product and service experience. We look forward to working with you to create a brilliant future! If you have any questions or needs, please feel free to contact us, we will be happy to serve you. Our professional team will provide customized solutions according to your specific needs to ensure the successful completion of your project.