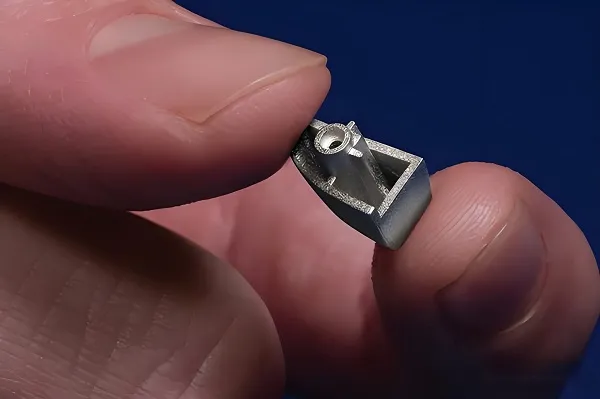

Brass turned parts are brass products that are machined through a lathe. They are usually of precise size and shape and are suitable for a variety of industrial, decorative and mechanical applications. Brass, as an alloy, is mainly composed of copper and zinc and has excellent electrical conductivity, corrosion resistance, good mechanical properties and beautiful golden luster.

1.Brass Turned Parts Characteristics

Brass turned parts have the following remarkable properties:

Corrosion resistance: brass has good corrosion resistance to a variety of chemicals, suitable for a variety of environments.

Conductivity: brass is a good conductor, suitable for electrical connections and conductive parts.

Mechanical properties: brass has good strength and toughness, able to withstand certain loads and deformation.

Aesthetics: brass has a unique golden luster, after processing, it can present a smooth, bright appearance.

2.Production process of brass turned parts

The production process of brass turned parts mainly includes the following steps:

Material preparation: choose high quality brass materials, such as common brass, special alloy brass, etc., to ensure product quality.

Drawing design: design and draw detailed drawings according to customers’ requirements, specifying the size, shape and tolerance requirements of the products.

Lathe machining: use advanced CNC lathe equipment to carry out precision machining according to the drawings to ensure the size and shape accuracy of the products.

Quality Inspection: Conduct quality inspection such as size measurement and appearance inspection on the finished products to ensure that the products meet the design requirements.

Surface treatment: According to the customer’s demand, we carry out polishing, plating and other surface treatment to enhance the beauty and corrosion resistance of the products.

3.Processing technology of brass turned parts

The machining process of brass turned parts mainly includes cutting, drilling, milling, turning and so on. We adopt advanced CNC lathe equipment, combined with precise measuring tools, to ensure the machining accuracy within ±0.01mm. At the same time, we have rich processing experience and technical strength, and can provide personalized processing technology solutions according to customer needs.

4.Surface treatment process of brass turned parts

The surface treatment process of brass turned parts mainly includes polishing, plating, spraying and so on. Polishing can remove the burrs and scratches on the surface of the product, making it present a smooth and bright appearance. Electroplating can form a protective film on the surface of the product to improve the corrosion resistance and aesthetics of the product. Spraying can provide customized color and functional coatings according to customer needs.

5. Application areas of brass turned parts

Brass turned parts are widely used in various fields, including but not limited to:

Electrical industry: for electrical connections, conductive parts, etc.

Decorative industry: used for making decorations, artworks, etc.

Mechanical industry: used for making mechanical parts, fasteners, etc.

Automobile industry: used for making automobile parts, decorations, etc.

Construction industry: used to make architectural hardware, decorative parts, etc.

Customized brass turned parts FAQ

Q1: What is the machining precision of brass turned parts?

A: The machining accuracy of our brass turned parts can reach within ±0.01mm, which ensures the size and shape accuracy of the products.

Q2: What are the options for surface treatment of turned brass parts?

A: The surface treatment of our turned brass parts includes polishing, plating, spraying and other options, which can be customized according to customer needs.

Q3: How long is the production cycle of turned brass parts?

A: The production cycle mainly depends on the complexity and quantity of the product as well as the preparation of raw materials. Generally speaking, it takes 5-15 working days from drawing design to finished product delivery.

Q4: Do you support customized brass turned parts?

A: Yes, we provide a full range of customization services, including material selection, drawing design, machining process, surface treatment, etc., to ensure that the products can fully meet customer needs.

Q5: How to calculate the price of Turned Brass Parts?

A: The price mainly depends on the size, shape, quantity and processing difficulty of the product. We will provide a detailed quotation program according to the specific needs of customers.

By choosing our Customized Brass Turned Parts service, you will enjoy high quality, high efficiency and personalized service experience. We look forward to working with you to create a bright future together!