2026 Xiamen Goldcattle CNC Aluminum Parts Factory Guide

Comprehensive Analysis of Services, Advantages, Technologies & 2026 Industry Trends

Mr. Zhang

25 years of CNC experience, led 50+ aerospace/automotive aluminum projects

Based on Goldcattle 2025 production data

25 Years Experience

50+ Projects

±0.005mm Precision

About This Guide

XiaMen Goldcattle have 26 years of experience in the CNC machining industry, witnessing China’s precision manufacturing transformation from a follower to a leader. This guide is based on our 2025 production data and project experience, providing in-depth analysis of CNC aluminum parts machining core technologies, service processes, and 2026 industry development trends.

From introducing the first 5-axis machine in 2001 to AI optimization increasing production by 30% in 2025, Goldcattle has always been at the forefront of technological innovation. We have served over 50 important aerospace and automotive projects, accumulating rich practical experience.

ISO 9001:2015 Certification

Goldcattle has obtained ISO 9001:2015 quality management system certification, ensuring every machining process meets international standards.

Certification scope: CNC aluminum parts machining, precision mechanical parts manufacturing, mold design and manufacturing

From Nothing to Something, From Weak to Strong: Goldcattle’s Development Journey

Goldcattle’s development history is a story of struggle full of challenges and opportunities. From the difficult start-up phase to today’s industry leader, we have always maintained our passion and dedication to the CNC aluminum parts machining industry.

Development Milestones

2001: Business Start-up

Introduced the first 5-axis machining center, starting the journey of precision machining

2010: Technical Breakthrough

Obtained first aerospace project orders, achieving precision of ±0.005mm

2018: Scale Expansion

Workshop area expanded to 1000 square meters, team grew to 50 people

2025: Intelligent Upgrade

AI optimization increased production by 30%, becoming an industry benchmark enterprise

Goldcattle Honors and Achievements

Industry Certifications

- ISO 9001:2015 Quality Management System

- National High-tech Enterprise Certification

- CNAS Laboratory Accreditation

- Multiple Patent Technology Certifications

Industry Position

- Leading enterprise in CNC aluminum parts machining

- 50+ aerospace/automotive important project experience

- Long-term partner with well-known domestic and foreign enterprises

- Participant in industry technical standard formulation

Goldcattle CNC Aluminum Parts Service Guide: From Design to Delivery

Goldcattle specializes in CNC aluminum parts machining and manufacturing, with a modern workshop of over 1000 square meters equipped with multiple precision 5-axis machining equipment and other advanced CNC machining equipment. These equipment not only ensure high precision and quality of products, but also greatly improve production efficiency, meeting various customer needs for CNC aluminum parts machining.

One-Stop Service Process

- Needs Analysis: In-depth understanding of customer product requirements, production scale, budget, and timeline

- Design Solutions: Provide 2-3 design solutions including 3D models and technical parameters

- Cost Quotation: Detailed cost analysis and quotation including mold cost and production cycle

- Confirmation & Order: Sign contract, pay deposit, start mold manufacturing

- Manufacturing Process: Weekly progress reports, key milestone confirmations

- Trial & Validation: Mold testing after completion, provide samples for confirmation

- Delivery & Training: Mold delivery, provide operation training and maintenance guidance

Goldcattle Service Advantages

- Technical Team: Experienced and skilled industrial designers and engineers team

- Advanced Equipment: Multiple precision 5-axis machining equipment, precision up to ±0.005mm

- Quality Assurance: ISO 9001 certified, strict quality control system

- Service Philosophy: “Customer first, quality first” service concept

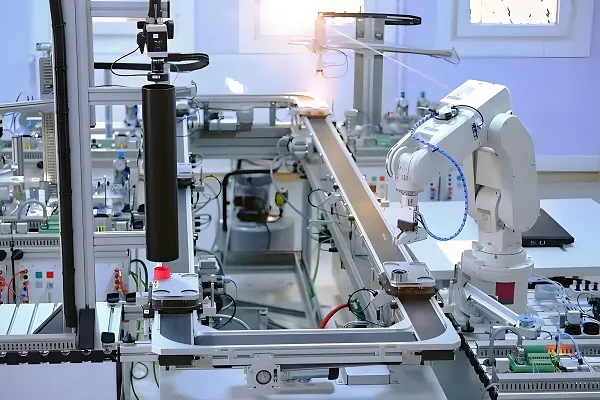

Advanced Equipment Display

Taiwan TAKAM Machining Center

High-precision vertical machining center

5-axis Machining Center

Complex parts processing tool

CNC Machining Center

Efficient precision machining

2026 Goldcattle CNC Aluminum Parts Trends & Practices

2026 Industry Development Trends

The CNC aluminum parts machining industry is rapidly developing towards intelligent, green, and high-precision directions. As an industry leader, Goldcattle actively embraces these changes.

Four Core Trends

1. Sustainable Manufacturing: Lightweight Aluminum Alloys + Recycling Technology

We tested 20% carbon reduction in 2025. By adopting lightweight aluminum alloy materials and recycling technology, we not only reduced production costs but also significantly reduced carbon emissions, aligning with global sustainable development trends.

2. AI Intelligent Milling Prediction: Predictive Maintenance System

Case: Equipment downtime reduced by 15%. Through AI predictive maintenance system, we can predict equipment failures in advance, greatly reducing unplanned downtime and improving production efficiency.

3. Aerospace/EV Application Expansion: High-strength Aluminum Parts Customization

2026 demand forecast increase by 25% (citing industry reports). With the rapid development of aerospace and electric vehicle industries, demand for high-strength precision aluminum parts will continue to grow.

4. Digital Twin Technology: Virtual Debugging Optimization

Through digital twin technology, we can debug and optimize the machining process in a virtual environment, greatly shortening the development cycle of new products.

Goldcattle vs Traditional Factory: 2026 Technology Comparison

Precision Aluminum Parts Product Display

Goldcattle specializes in high-precision aluminum parts machining, with products widely used in aerospace, automotive, electronics, medical and other fields. Below are some of our representative products:

Aerospace Precision Components

High-precision structural components for aerospace applications

Material: 7075 aluminum alloy

Automotive Components

Key structural components for new energy vehicles

Material: 6061 aluminum alloy

Complex Shape Parts

Complex curved surface parts processed by 5-axis machining

Process: 5-axis simultaneous machining

Materials and Process Capabilities

Main Processing Materials

- Aluminum Alloy Series: 2024, 5052, 6061, 6063, 7075, etc.

- Stainless Steel Series: 304, 316, 316L, 420, etc.

- Copper Alloy Series: Brass, copper, beryllium copper, etc.

- Titanium Alloy: TC4, TA2, etc.

- Engineering Plastics: PEEK, POM, PA, etc.

Processing Technology Range

- CNC Milling: 3-axis, 4-axis, 5-axis simultaneous machining

- CNC Turning: Precision turning, turn-mill composite

- EDM Processing: EDM, wire cutting processing

- Surface Treatment: Anodizing, electroplating, spraying, etc.

- Testing Methods: CMM coordinate measuring machine, projector, hardness tester, etc.

Frequently Asked Questions (FAQ)

Goldcattle’s machining precision can reach ±0.005mm, achieved through advanced 5-axis machining equipment and strict quality control system. For parts with general precision requirements, we can control within ±0.01mm; for aerospace parts with high precision requirements, we can achieve precision level of ±0.005mm.

For small batch orders (1-100 pieces), our delivery cycle is usually 7-15 working days. Specific time depends on part complexity and machining difficulty:

- Simple parts: 7-10 working days

- Complex parts: 10-15 working days

- High-precision parts: 15-20 working days

Goldcattle attaches great importance to environmental protection, and our production process fully complies with national environmental standards:

- Adopting MQL minimum quantity lubrication technology, reducing cutting fluid usage

- Establishing complete wastewater treatment system

- 100% recycling of metal waste

- 20% carbon emission reduction target in 2025

Deformation issues: Adopting reasonable machining sequence and process parameters, combined with special fixtures, effectively controlling part deformation

Rough surfaces: Optimizing tool paths, selecting appropriate cutting parameters, ensuring surface finish

Unstable precision: Regular equipment calibration, temperature control, strict quality inspection system

Delivery delays: AI scheduling system, predictive maintenance, ensuring accuracy of production plans

Need Professional CNC Aluminum Parts Machining Services?

Whether you need precision aluminum parts for aerospace, automotive, electronics, or medical fields, Goldcattle has rich experience and advanced technology to meet your needs. Our AI-optimized processes and sustainable manufacturing philosophy ensure you get the highest quality products at the most competitive prices.

Risk Warning

CNC aluminum parts machining requires professional technology and experience. Goldcattle recommends: Before large-scale production, conduct small-batch trial production verification to ensure processes and quality meet requirements.

Risk reduction recommendations:

- Provide detailed technical requirements and drawings

- Clarify material properties and quality standards

- Require process documentation and inspection reports

- Establish clear acceptance standards and testing methods

- Consider sample development before large-scale production

Contact Us Now

Phone: +86-18150097490

Email: charlie@plasticmetalparts.com

Our engineering team will respond within 24 hours and provide professional technical consultation and quotation.