Introduction: Defining the Technologies

Computer Numerical Control (CNC Machining) and Milling are foundational technologies in modern manufacturing. While often confused, they serve distinct roles:

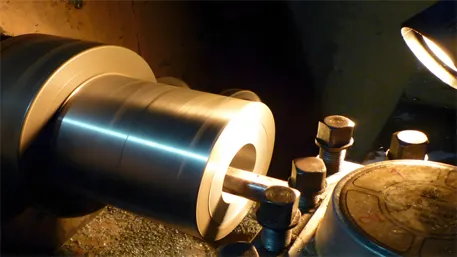

- CNC Machining refers to a broad range of automated subtractive processes (e.g., turning, drilling, grinding) controlled by programmed software.

- Milling specifically involves removing material using rotating cutting tools, typically for flat or contoured surfaces.

Industry Insight:

The global CNC machining market is projected to exceed $100 billion by 2025, with the U.S. dominating 35% of demand (Statista, 2023). This growth is driven by industries like aerospace, automotive, and medical devices seeking precision and scalability.

CNC Machining vs Milling: Technical Breakdown

1. Process Scope

| Aspect | CNC Machining | Milling |

|---|---|---|

| Operations | Multi-process (milling, turning, etc.) | Single-process (material removal via rotary tools) |

| Complexity | Handles 3D geometries (e.g., turbine blades) | Best for 2.5D shapes (e.g., gears, brackets) |

| Equipment | Multi-axis CNC machines (5-axis+) | 3-axis milling machines |

Example:

Aerospace companies use 5-axis CNC machining to produce titanium engine components, while milling machines craft aluminum alloy brackets for automotive frames.

2. Precision and Tolerance

- CNC Machining: Achieves tolerances as tight as ±0.001 mm for critical medical implants.

- Milling: Typically maintains ±0.01 mm tolerance, suitable for industrial tooling.

Industry Applications: Where Each Technology Shinesa

1. Automotive Manufacturing

- CNC Machining: Engine blocks, transmission shafts (high-strength steel).

- Milling: Gearbox housings, brake calipers (aluminum alloys).

Case Study:

Tesla leverages CNC-machined copper connectors for battery modules, ensuring conductivity and heat resistance.

2. Medical Devices

- CNC Machining: Titanium spinal implants (biocompatible, complex geometries).

- Milling: Stainless steel surgical instruments (sterilization-compatible surfaces).

Stat: 78% of medical OEMs prioritize CNC machining for FDA-compliant parts (McKinsey, 2022).

How to Choose: A Decision-Making Framework

Step 1: Evaluate Your Needs

| Factor | Choose CNC Machining If… | Choose Milling If… |

|---|---|---|

| Part Complexity | 3D contours, internal features | Flat/angled surfaces, pockets |

| Material | Exotic metals (Inconel, titanium) | Aluminum, plastics, mild steel |

| Volume | Prototypes & low-to-medium batches | High-volume production |

Step 2: Cost-Benefit Analysis

- CNC Machining: Higher upfront costs (150–150–500/hour) but lower per-unit cost for complex parts.

- Milling: Lower hourly rates (50–50–150/hour) for simpler, high-volume jobs.

Tip: Use AI quoting tools (e.g., Xometry) to compare real-time pricing.

Why Partner with a Custom CNC Service Provider?

- Speed: Rapid prototyping in 3–5 days vs traditional 2-week lead times.

- Certifications: ISO 9001, AS9100, and ITAR compliance for regulated industries.

- Sustainability: 85% material efficiency via CNC optimization vs 65% in conventional milling.